"At NEST, the MESH technology has achieved the breakthrough"

-

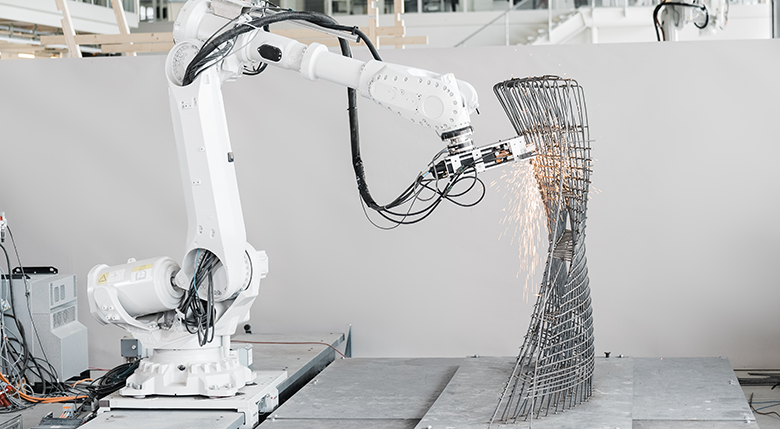

The innovative MESH technology uses robots to produce a 3D grid structure that simultaneously forms the reinforcement and formwork. This enables the production of complex, customized concrete structures.

-

In 2018, the ETH researchers used their process for the first time on the construction site during the construction of the NEST unit DFAB HOUSE. In this way, they were able to demonstrate that their research works in practice.

-

They now reached another milestone on the way to market maturity: the founding of the ETH spin-off MESH AG.

The goal of NEST is to support partners in bringing their innovations from the laboratory into practice. With the foundation of the ETH spin-off MESH AG in 2022, this goal could be achieved once again.

More efficiency by combining functions

The MESH technology was developed at ETH Zurich during ten years of intensive research. With this robot-assisted technology, it is possible to manufacture complex or curved reinforcement cages using an automated prefabrication process – more easily, more cost-effectively and more material-efficiently than the current manual production. These reinforcement structures allow the realization of customized concrete structures in a wide range of dimensions. The robot sets and welds a 3D grid structure that is specified by a digital model. A special concrete mix is then filled into the grid. This is not only the reinforcement, but also the formwork of the concrete structure.

From the lab to the construction site

On its way to market maturity, the innovative MESH technology also made an important stop at NEST. In 2018, the researchers used it in the NEST unit DFAB HOUSE to build the s-shaped wall on the first floor of the three-story module. It measures a total of 12 meters and supports the approximately 100-ton load of the upper two floors. The ETH team was thus able to demonstrate that the technology not only works in the laboratory, but also on the construction site – a breakthrough for the researchers.

Entry into the market

In recent years, the team transferred the innovative process into an industrial construction process in collaboration with PERI and Sika. The latest milestone: the official foundation of the spin-off MESH AG, in which the two companies are also involved. For Ammar Mirjan, CEO of MESH AG, it is clear: "With the foundation of our MESH AG and the partnership with PERI and Sika, we can now jointly establish our technology in the construction industry and thus help it to achieve greater freedom of form, sustainability and efficiency."