NEST – Exploring the Future of Buildings

NEST is the modular research and innovation building of Empa and Eawag. At NEST, new technologies, materials and systems are tested, researched, further developed and validated under real conditions. Close cooperation with partners from research, industry and the public sector ensures that innovative construction and energy technologies are put onto the market faster. NEST contributes to making the use of resources and energy more sustainable and circular.

Innovative building materials for NEST's Beyond.Zero unit

Omya and NEST, the research and innovation platform of Empa and Eawag, have entered into a new partnership. Together with additional partners, they will begin planning and constructing the new NEST unit Beyond.Zero in August 2025. The goal is to develop and test CO₂-reduced and CO₂-negative materials and technologies across the entire life cycle of buildings.

The die is cast

For several weeks now, visitors to Empa have been greeted by a special eye-catcher: ten Empa cubes, including nine planted cubes and one copper-colored Corten steel cube with the Empa logo, have redesigned the entrance area. These plant cubes not only create a green accent on the campus, but also invite visitors to slow down and promote biodiversity.

New technologies for resource-efficient construction developed to market readiness

A digitally manufactured staircase that winds its way up to the second floor. A wafer-thin, perforated concrete ceiling that absorbs sound. Floor and wall materials made from recycled waste. The latest unit in the NEST research and innovation building at Empa is a beacon for material-saving and energy-efficient construction technologies. The STEP2 unit is officially opened.

Selected success stories

When façades learn to speak: How applied design can promote the energy transition

How can design and visual communication accelerate the energy transition? Design student Jenna Wittkopf addressed this question as part of her bachelor's thesis. She has designed multifunctional PV modules that serve several purposes simultaneously: In addition to efficient energy production, the modules can be visually integrated into the building and also serve as a call to action.

"NEST provides the ideal environment to further develop our innovation"

As part of the HiLo project at NEST, researchers from the Chair of Architecture and Building Systems at ETH Zurich have developed an innovative adaptive solar façade that simultaneously optimizes electricity production and energy savings. Demonstrators of the façade were tested at the HiLo unit. With the founding of the ETH Zurich spin-off "Zurich Soft Robotics", the product is now to be brought to the market under the name "Solskin".

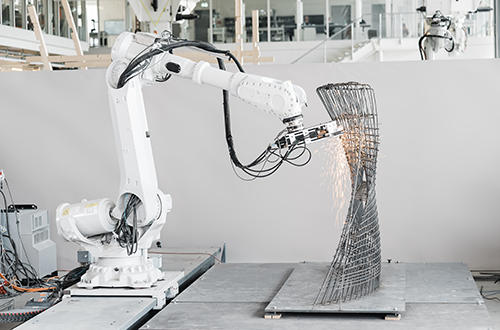

"At NEST, the MESH technology has achieved the breakthrough"

The innovative MESH technology uses robots to produce a 3D grid structure that simultaneously forms the reinforcement and formwork. This enables the production of complex, customized concrete structures. The ETH researchers used their process for the first time on the construction site during the construction of the NEST unit DFAB HOUSE showing They now reached another milestone on the way to market maturity: the founding of the ETH spin-off MESH AG.