Success stories

At NEST, partners from business, research and the public sector work together to validate, develop and ultimately make their ideas marketable. Our success stories provide an insight into this collaboration and show what can result from it.

When façades learn to speak: How applied design can promote the energy transition

How can design and visual communication accelerate the energy transition? Design student Jenna Wittkopf addressed this question as part of her bachelor's thesis. She has designed multifunctional PV modules that serve several purposes simultaneously: In addition to efficient energy production, the modules can be visually integrated into the building and also serve as a call to action.

"NEST provides the ideal environment to further develop our innovation"

As part of the HiLo project at NEST, researchers from the Chair of Architecture and Building Systems at ETH Zurich have developed an innovative adaptive solar façade that simultaneously optimizes electricity production and energy savings. Demonstrators of the façade were tested at the HiLo unit. With the founding of the ETH Zurich spin-off "Zurich Soft Robotics", the product is now to be brought to the market under the name "Solskin".

"Thanks to our participation in the NEST project, we can now be part of the change"

In the Sprint project, partners from research and industry worked together from the very beginning to build a new NEST unit in the shortest possible time, largely with reused materials. In this interview, Maike Stroetmann from Bouygues Energies & Services talks about the challenges of the project for her and her team and the knowledge they gained in the process.

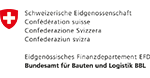

"At NEST, the MESH technology has achieved the breakthrough"

The innovative MESH technology uses robots to produce a 3D grid structure that simultaneously forms the reinforcement and formwork. This enables the production of complex, customized concrete structures. The ETH researchers used their process for the first time on the construction site during the construction of the NEST unit DFAB HOUSE showing They now reached another milestone on the way to market maturity: the founding of the ETH spin-off MESH AG.

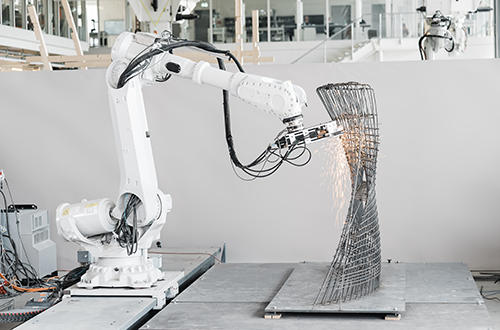

Acoustics from the 3D printer

In the STEP2 unit's floor slab project, the team developed a novel acoustics solution that will be discreetly integrated into the ribbed filigree slab: A box from the 3D printer. It enables a high acoustics quality of a room despite a sound-reflecting surface and extends the design freedom for the architects.

"NEST offers startups a real environment equipped like a perfect laboratory"

The Zurich-based startup Oxygen at Work uses selected plant species to improve the air quality and energy efficiency of office buildings. In order to further optimise its services, the company works together with NEST. In the Meet2Create Unit, new plant concepts in combination with new technologies are being validated and further developed.

"Wastewater is a source of nutrients, energy and water"

Circular economy holds great potential when it comes to wastewater. At NEST, Eawag, Keramik Laufen AG and Vuna are working together to further advance this topic by processing urine into a marketable fertilizer.

"At NEST we were able to show that our algorithm can save 25 percent energy"

Empa researchers used NEST as a research platform to test and further develop an innovative, self-learning heating control system. The result: the intelligent control system achieved a higher level of comfort with less energy.

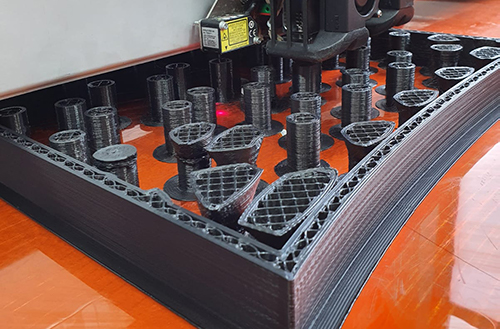

"The collaboration with research was very inspiring"

The NEST unit DFAB HOUSE is the first house in the world that was largely built digitally. ERNE AG Holzbau acted as general planner. The company now also uses a robotic production method, which was applied in DFAB HOUSE for the first time, for its own projects.

"The partnership enables a worldwide unique product portfolio"

The NEST partners 3E Flow and Georg Fischer AG are launching a partnership. In autumn 2020, the two companies will bring an internationally unique product offer to the Swiss market that greatly optimizes the energy consumption of the water cycle.

"Thanks to NEST, ideas have turned into products"

The office furniture supplier Lista Office LO has been a NEST partner from the very beginning. In cooperation with the Competence Centre for Typology & Planning in Architecture (CCTP) at Lucerne University of Applied Sciences and Arts, the company used the NEST Meet2Create unit to test and further develop prototypes of new furniture systems in everyday life. Several of these further developments are now on the market and are being sold successfully.