Liquid-core Fibers

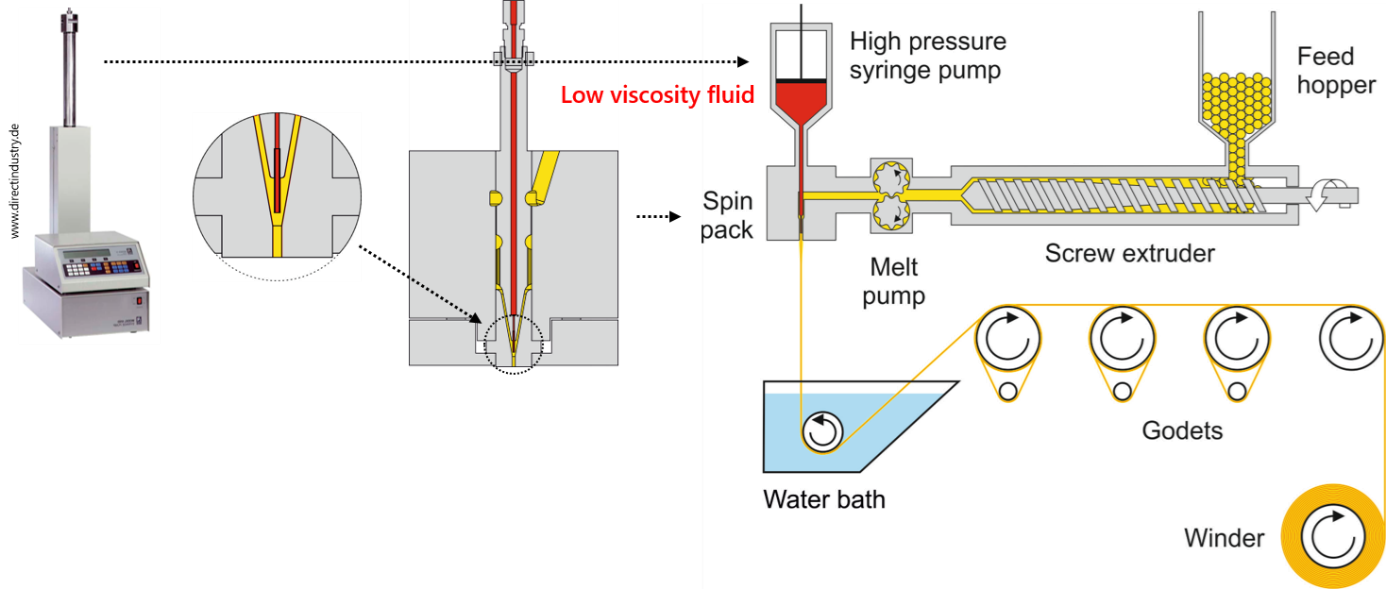

One of our core competences is the manufacturing of liquid-core fibers through melt-spinning. A suitable liquid (high thermal stability, low vapor pressure (< 1 atm) at processing temperatures) is injected into the polymer melt using a special spinneret die.

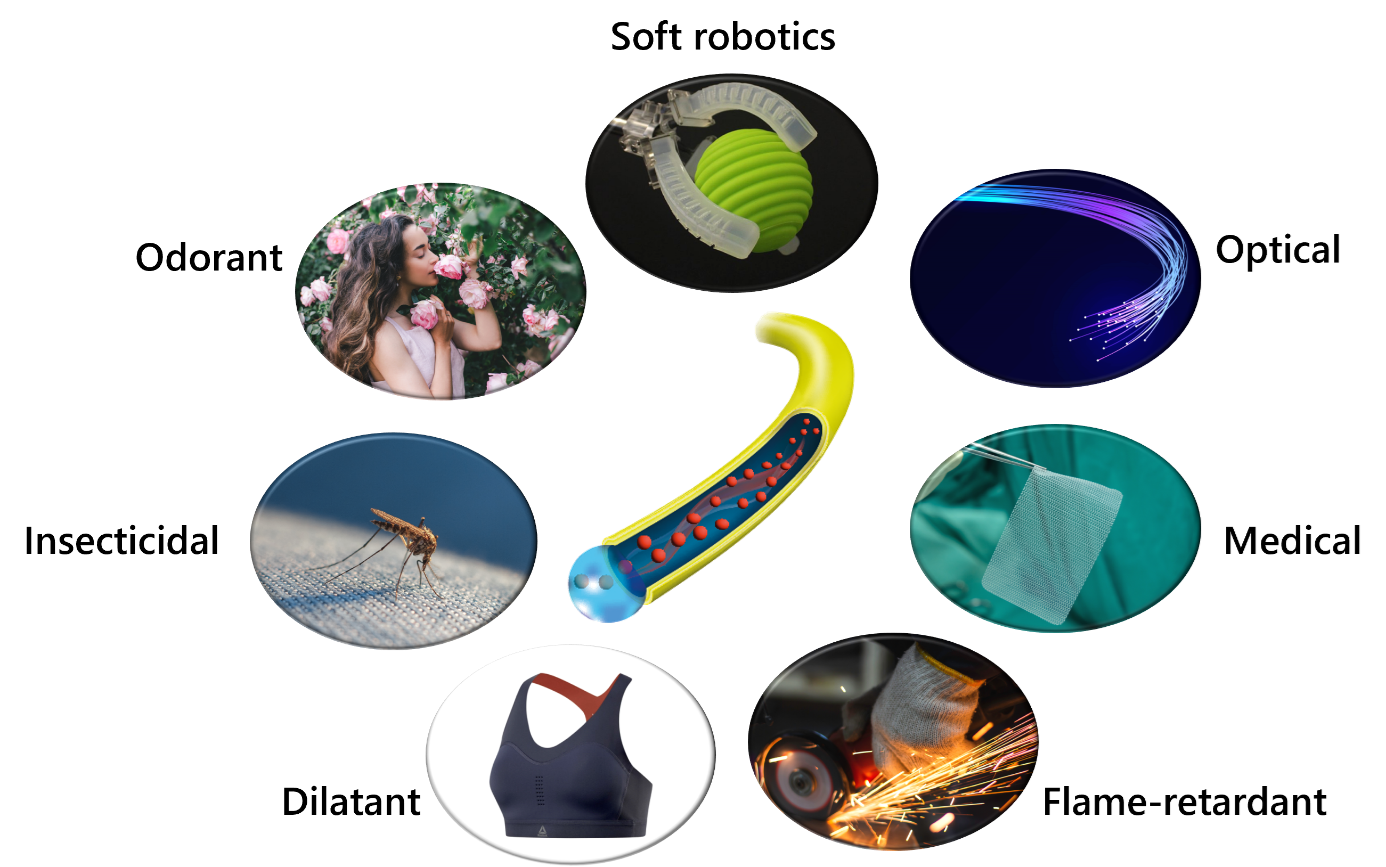

Liquids in the core of a synthetic filament can provide unprecedented properties to textiles and composites, without compromising mechanical properties, dyeability or washability. We pursue various industry-relevant applications of liquid-core fibers.

Highlight: Medical liquid-core fibers

We recently added medical drugs to liquid-carrier materials with the intention to develop a new generation of melt-spun medical fibers for targeted and local drug-delivery (Röthlisberger, M., et al. (2024). "Drug delivery with melt-spun liquid-core fibers." Polymer 298: 126885). A project starting on 1.4.2025 focuses on developing anti-pain, anti-inflammatory and antimicrobial hernia repair meshes based on this new technology.