STEP2 news update

The path to the completed STEP2 unit consists of many different decision-making and development processes. The STEP2 news update takes you along this path and shows the most important milestones until the completion of the unit.

The STEP2 façade is installed

March 2024 – The prefabricated STEP2 façade was integrated into the unit in just two days in mid-March. The modules were produced at Aepli Metallbau AG. The design of the building envelope allows certain elements to be easily re-placed. This means that new innovations can also be integrated into the façade in the future at a reasonable cost and with few restrictions on operation. Innovative shading solutions, controlled natural ventilation and new insulation systems will be implemented in the initial phase of operation – planned in cooperation with the other unit partners BASF, WaltGalmarini AG and ROK Architekten. Detailed information on the STEP2 building envelope can be found here.

Prominent visitor to the STEP2 unit

March 2024 – Innovations are created faster and better in close cooperation between industry and research. This is precisely why BASF is involved in NEST as the main partner of the STEP2 unit. In March, BASF CEO Martin Brudermüller visited the site to see the construction progress for himself and was impressed by the first visible innovations. Together with Empa Director Tanja Zimmermann and ETH Board President Michael Hengartner, he discussed the importance of close collaboration between research and industry for a sustainable use of our natural resources.

Start of construction

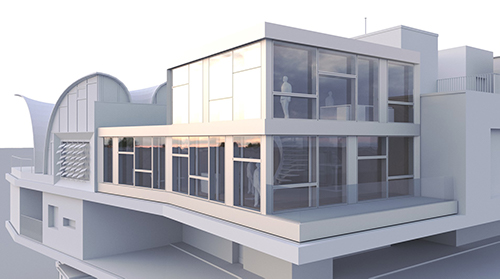

October 2023 – After the three-year planning phase in which partners from different disciplines jointly developed market-ready innovations, construction of STEP2 has now started. Read more here.

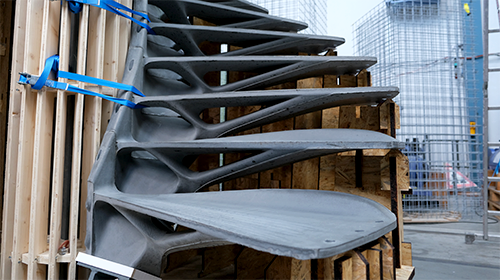

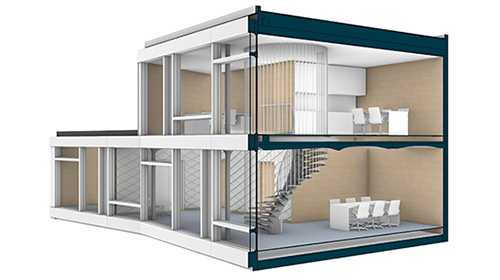

Successful assembly of the STEP2 staircase

August 2023 – Over the past few weeks, the project team has assembled the STEP2 staircase system, which now goes by the name "Cadenza". First, the individual prefabricated steps were stacked on top of each other in Empa's construction hall. The ultimate test was the subsequent prestressing with steel elements made of a memory alloy. This was successful on the first attempt, and the staircase is now ready to be transported as a single element from the construction hall to NEST later in the year and then installed in the unit. Comprehensive information on the STEP2 staircase can be found here.

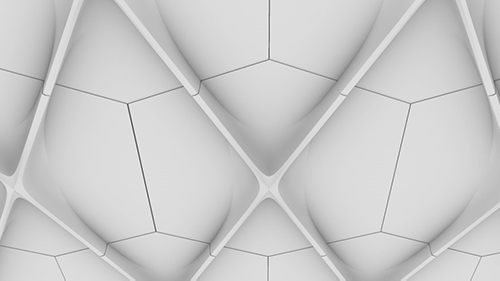

Successful filling of the acoustics boxes

June 2023 – 3D-printed acoustics boxes will be used in the slab project. These will be discreetly integrated into the filigree ceiling and enable a high acoustic quality despite the sound-reflecting surface. Following production of the boxes, the team has now successfully filled them with the mineral-based insulation material Cavipor, which will provide the acoustic absorption. With that step, they are now ready for their application in the slab. Please find further information on the subject here.

The platform is ready for the construction of the unit

Juni 2023 – The preparations for the start of construction are in full swing. The NEST platform on which the unit will be built is now prepared. The STEP2 partners celebrate this milestone together with a symbolic "broom sweep".

Go-ahead for STEP2 staircase

February 2023 – The globally unique staircase system that the partners have been working on for the past two years has reached an important milestone. The staircase, which is manufactured using computational design and 3D-printed formwork, has passed the final prototype tests and can now be built. The full story can be found here.

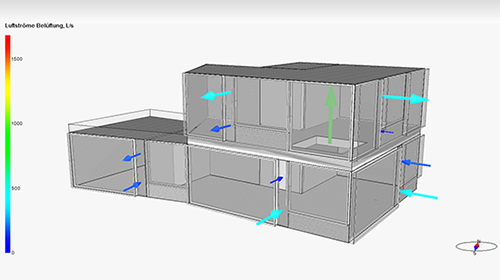

Finished energy and thermal comfort concept

Spring 2022 – The energy and thermal comfort concept of the unit was successfully finalized. It defines the interaction of the various components - such as the innovations in the façade or the heating and cooling system - with the aim of optimizing the energy efficiency and comfort of the STEP2 unit.

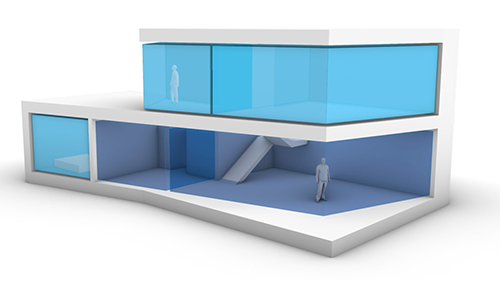

Completed preliminary planning of the building envelope

Spring 2022 – The team has completed the preliminary planning of the building envelope. Various shading and insulation innovations will be used. These include high-performance glass, a new type of shading system in the spaces between the windowpanes, and a light control system for large room depths - all integrated into a next-generation closed cavity façade. The project team is now working on the execution planning of the façade and the development of the different innovation objects.

Slab planning completed

Spring 2022 – The planning for the ribbed filigree slab, which will set new standards in terms of resource and cost efficiency, is now complete. In the next step, the project team will produce a prototype of the slab and put it through different practical tests. At the same time, this project is already delivering another market-ready solution: ROK's newly developed digital design and planning tool, with which this new floor system can be generated automatically from the design to the production geometry in a very short time.

Successful first stair prototype

Winter 2021 – Digital planning methods and 3D-printed formwork are used to realize the staircase in the form of a human spine. The first prototype has already shown that the planned manufacturing process works in practice. A first stair step was put through a load test at Empa and achieved consistently positive results. In the next step, a second prototype consisting of three to five steps will be manufactured and undergo further structural tests.

The main partner BASF draws a first conclusion

November 2021 – Almost one year after the official launch of the STEP2 unit, the main partner in the project – BASF – looks back on what has already been achieved and talks about the potential of STEP2. Please find further information in the statement video here.

First prototypes successfully realized

Summer 2021 – The STEP2 team was able to reach an important milestone in both the slab and the stair project: The realization of the first prototypes. In the case of the slab, an innovative acoustics box from the 3D printer was successfully produced and integrated into a prototype of the slab. Read more about this in the success story. For the staircase, the first steps were manufactured and are now undergoing a load test.

What has happened so far

Prior to the launch of the STEP2 news update in December 2020, several milestones have already been reached in the project. Please find an overview of the most important ones below.

Breakthrough in material requirement of the floor slab

A ribbed filigree slab already requires around a third less material than a conventional filigree slab. With the help of its specially developed design tool, the ROK architects' office succeeded in September 2020 in reducing the resource consumption even further. The latest design requires only one quarter of the material of former designs.

Overall energy concept completed

A main emphasis of the STEP2 unit is energy management. WaltGalmarini AG contributes its expertise in this field of research. The company has been involved since the beginning of 2019 and has developed a comprehensive energy and building physics concept for STEP2. In addition to energy efficiency, the focus lies on optimizing user comfort. WaltGalmarini AG completed the overall energy concept at the end of June 2020.

Financing secured

The project team's funding application for STEP2 was approved in June 2020.

Development of a digital design tool

In early 2020, ROK launched an innovative digital design tool developed specifically for the planning of the ribbed filigree slab. This was an important step in the planning process of the floor slab.

Industry partner aboard the floor slab project

Experience from previous NEST units had shown that the prefabrication of concrete slab elements using 3D printing offers enormous potential. For STEP2, the project team developed a business case for a marketable, resource-efficient floor slab that can cover spans of up to 20 meters. In fall 2019, Stahlton AG expressed its interest in participating in the project and committed to realizing the innovative floor slab concept.

Convincing business case for the building envelope

The building envelope and the related energy concept are central elements of STEP2. In order to find further industry partners for the project, BASF, NEST and ROK worked out a business case for the building envelope - and convinced Aepli Metallbau AG to participate as a project partner in late summer 2019.

The staircase becomes an innovation object

At first, the staircase that will lead to the second floor of the unit was not perceived as an innovation object. However, through discussions with researchers from the ETHZ Institute "Digital Building Technologies", the project team recognized the potential of using construction technologies developed at ETHZ to design an innovative spiral staircase. The stairs will be manufactured by 3D printing. In addition to the ETHZ researchers, BASF's subsidiary "BASF Forward AM" is contributing its expertise in industrial 3D printing to the project. SW Umwelttechnik, which joined the project in autumn 2019, will manufacture the innovative staircase.

Birth of an idea

The idea for the STEP2 unit was born in 2018, driven by BASF's strategy to develop innovative solutions along the value chain together with partners. The company recognized that NEST would be the ideal platform to put this strategy into practice and therefore approached the NEST team early in the process. The decision to realize a new NEST unit was quickly made. After that, the architectural office ROK joined the core team as planning partner. The team defined suitable innovation objects for the unit as well as the room layout. With ROK conducting the first volume study the architectural process officially started.

About STEP2

Abo

Want to stay up to date on how the construction of STEP2 is progressing or what exciting things are happening at NEST and Empa in general? Then sign up here for our media subscriptions.