High-energy X-ray Imaging

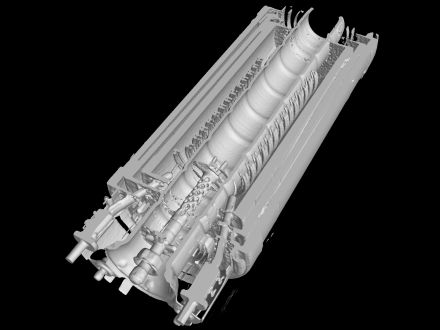

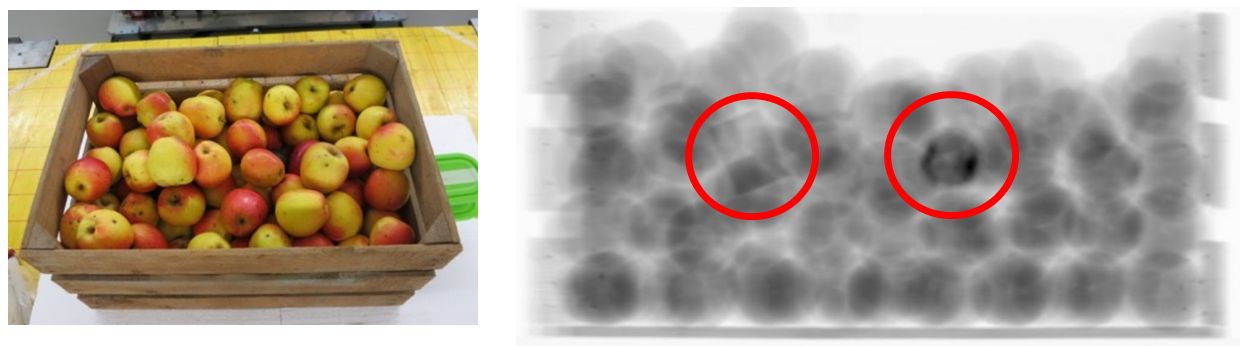

Are you interested why your component broke, how to measure the geometry of your sample accurately or how your product changed after intense operation? All these questions can be addressed with X-ray computed tomography.

The Empa Center for X-ray Analytics is a member of the ANAXAM Technology transfer center and contributes and supports especially in area of high-energy imaging and image processing problems. E-paper from polyscope': Ausgabe 02/2022.

The X-ray sources available at the Center for X-ray Analytics cover a broad range up to an X-ray energy of 6 MeV, which allows to penetrate steel up to 300mm. High spatial resolution can be achieved using a 300 kV high energy microfocus tube. Typical applications are failure analysis in broken appliances to identify defects non-destructively, 3D modelling of structures, metrology for first article inspection, and the monitoring of dynamical processes.

Furthermore we develop new methodologies for airport security and cargo inspection, high energy specific X-ray data acquisition procedures and application tools for image data processing. For the design and optimization of computed tomography systems we apply Monte Carlo simulations.

-

Share