μCT (micro Computed Tomography)

Characterisation

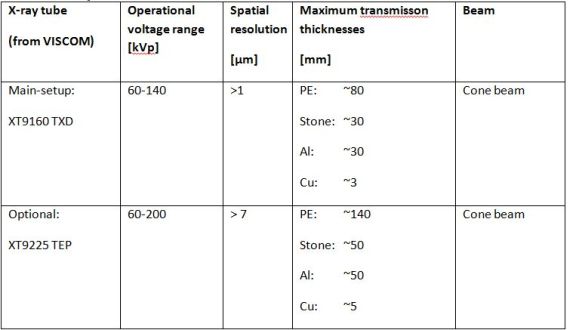

Because of the modular design the uCT setup can be flexibly adapted to different measurement requirements and therefore invites for additional and new setup components, for instance heating systems or differential phase contrast options.

Typical samples are in the dimensions from Milimeters to Centimeters, resulting in spatial resolution ranges from around 2 to >50µm.

Environment

- Air conditioned and temperatur regulated room

- Pressured air connection

- Air exhaust

Sample limitations for CTs

Maximum sample scanning height: 190mm

Maximum sample width: 80mm

Maximum sample weight: 5kg

Sample limitations for radiographies

Individual assessment.

- Filters (thin layers of different metals) can be mounted on the X-ray source in order to narrow the spectrum of the X-rays. An Al-filter can be mounted in front of the detector to reduce the detection of scattered photons.

- A high precision rotation table “UPR-160F air” from Micos mounted on a XYZ-stage made of three linear stages “LS-270” from Micos.

- The XYZ stage “LS-270” allows a positioning with a bidirectional repeatability of ± 2.5 μm and the rotation table “UPR-160F air” can rotate a load up to 5 kg with an accuracy of 0.05 μrad.

- The digital X-Ray detector is a “XRD 1621 CN3 ES” from Perkin Elmer, based on a 16'' amorphous silicon sensor operating as a two-dimensional photodiode array. X-Rays are converted into light using CsI (Tl) Scintillator, on which needles are directly deposited on the aSi photodiode. It has a a pixel size / pitch of 0.2 x 0.2mm2 and an image size of 2048 x 2048 pixels, resulting in a sensitive area of 409.6 x 409.6mm Transmission information is digitized in 16bit data range.

Currently available additional setups

- Differential phase contrast setup (limited field of view)

- Oven for heating examinations with radiographic time series

- Mini climatic chamber for temperature and humidity control.

Processing

The acquisition of the CT data is controlled by an in-house Labview©-software with an integration time of less than a second per projection. The projected images are corrected for pixel errors, offset and pixel gain (with the help of a dark and flat image). The 3D tomograms are reconstructed using GPU based, flexible in-house software tools which allow for optimal parameter settings for different materials. The reconstructed data-sets are finally processed and assessed by trained scientists to guarantee an optimal image quality.

-

Share