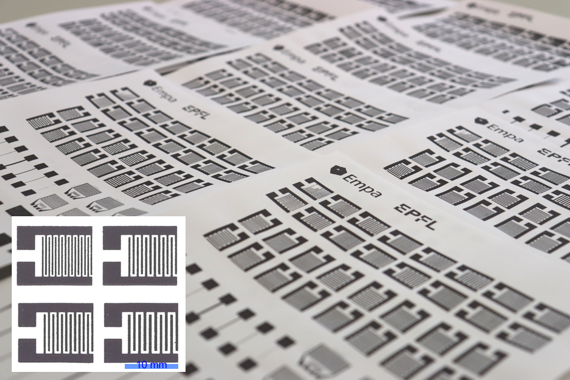

Screen Printing

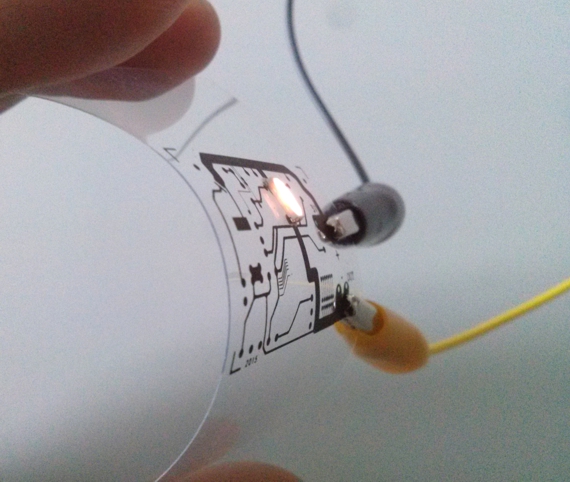

Screen printing is a very versatile printing technique for different applications. A fine mesh is used to transfer the ink onto the substrate. To print structures, the mesh has impermeable and permeable areas, where the ink is either blocked or not.

Key features

- Stencil is information carrier and screen

- Small components and large areas are possible

- Versatile process

- Usually high viscous inks are used

- Many different substrates possible

- Printing on different geometrical objects possible

- Web speed < 100 m/min

- Resolution ≤ 130 dpi, ≥ 25μm

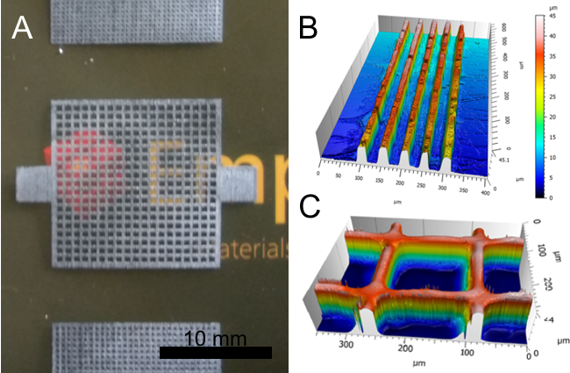

- Film thickness: 0.5 – 100 μm

Functional inks

Screen printing inks are usually high viscous liquids or pastes. This is an advantageous feature for functional inks, because the fraction of functional material in the ink (e.g. silver particles) can be very high. So the amount of functional material within the printed structure is also high, which yields a good performance (e.g. high conductivity). Compared to other printing techniques the film thickness of screen printed layers is much higher.

Turning Trash into Treasure: Additive Free MXene Sediment Inks for Screen‐Printed Micro‐Supercapacitors. Adv. Mater. 2020, 2000716. https://doi.org/10.1002/adma.202000716

-

Share