Gravure Printing

Gravure printing is a widely-used high quality, fast speed printing technique e.g. for magazine printing. It utilizes engraved cells on a printing plate or cylinder to transfer the ink to the substrate.

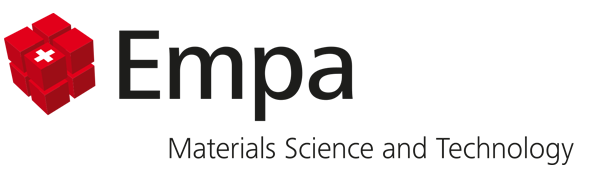

Schematic of the Gravure printing process and Photograph (left) and microscopic image (right) of engraved cells.

Key features

- Engraved elements on gravure cylinder.

- Mass-printing technique

- High variety of low viscosity inks can be used (UV, solvent, waterbased etc.)

- Web speed ≤ 100 m/min

- Resolution ≤ 355 dpi, ≥ 10μm

- Film thickness: 0.02 – 8 μm

Empa's gravure cylinder

Empa's gravure cylinder is specially designed for printing very fine details and structures required for printed electronics (down to 9 Micrometer). It is also has the capability to print very thin layers of functional inks.

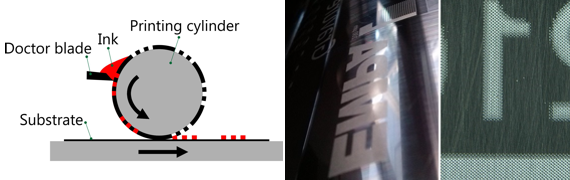

1 Printed Ag grids for use as transparent electrodes (https://doi.org/10.1007/s00170-019-03835-7).

2 Printed dot structure of polymeric material on PET foil.

3 Printed Ag current collector on CIGS solar cells.

4 Flexible and transparent electrode: A gravure printed conductive Silver grid and busbar on PET foil.

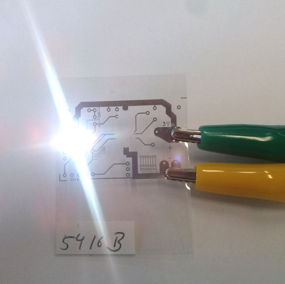

Circuit with a glue-bonded SMD-LED to prove conductivity of the gravure printed nano-silver ink.

Labratester

The CCC is also home to a small lab gravure printer for ink testing on flexible A5-sized substrates. Here, gravure plates are used, which allow a very fast workflow. A gravure plate with various cell parameters (e.g. depth, size) as well as a gravure plate with very fine structures are available.

Labratester

-

Share