Chemical Vapor Deposition (CVD)

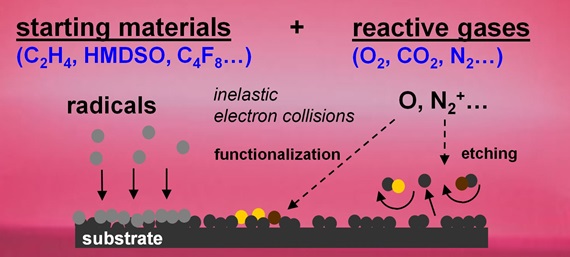

Plasma-enhanced Chemical Vapor Deposition (PECVD) is a process that converts the gaseous starting material (vapor) into thin films (deposit) via chemical reactions in the plasma and at the surface. Due to the energy delivered by the plasma, low process temperatures are feasible.

Film characteristics

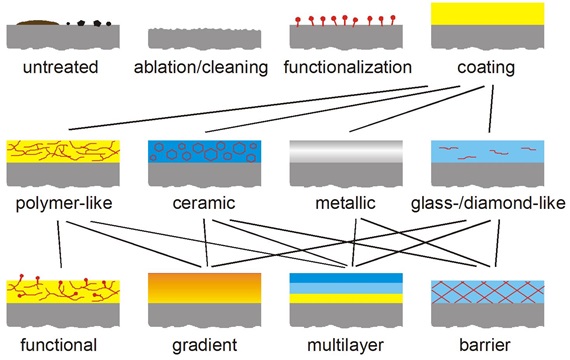

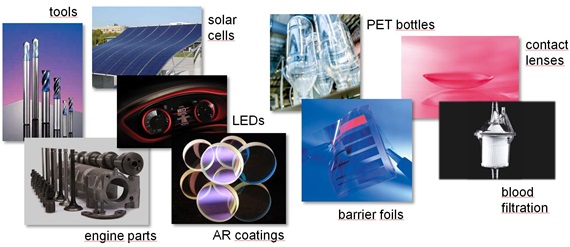

The selection of the starting materials (hydrocarbons, fluorocarbons, silanes, siloxanes, organometallics etc. mixed with reactive gases) and the plasma conditions (weak to strong chemical reactions) enable the deposition of a broad range of materials with polymer-like (functional films) and inorganic character (semiconductor, ceramic and diamond-like films). Furthermore, nanostructuring as well as vertical and lateral gradients can be achieved for advanced surface functionalities.

Plasma polymer films

Plasma polymer films are typically deposited at rather mild plasma conditions to enable incorporation of functional groups such as carboxyl, hydroxyl, amino, thiol or fluorocarbon. Nonetheless, cross-linking under well-defined plasma conditions enables stable and permanent films that are demanded e.g. for biomedical applications. Increasing cross-linking and densification finally results in the deposition of diamond-like carbon films.

Inorganic films

Pilot-scale reactors

-

Share