Ceramic Electrodes & Electrolytes

Our group investigates ceramic materials for energy conversion, storage, and related technologies. We study how electronic and molecular structure, transport properties, and functionality are linked, and how surfaces, interfaces, and defects influence material performance under realistic device operating conditions.

In collaboration with leading researchers and institutions worldwide, we have pioneered operando and in-situ characterization techniques ahead of their time, several of which are now widely adopted in the field. These joint efforts have helped to define the modern understanding of structure–property–function relationships in energy materials.

Using and developing operando and in-situ X-ray and neutron scattering and spectroscopy techniques, we study batteries, fuel cells, solid electrolytes, photoelectrochemical cells, and hybrid bio-inorganic assemblies—linking microscopic mechanisms to macroscopic behaviour.

Our research connects atomic-scale understanding with device-level functionality. By combining advanced characterization with mathematical modeling, we aim to uncover the mechanisms that govern performance and stability in electrochemical and photoactive materials, providing a foundation for informed materials design and responsible technological progress.

Our Research Topics

Our work explores how structure, transport, and reactivity interact in ceramic and hybrid materials for electrochemical and photoactive applications. The topics below reflect our main lines of inquiry and their natural extensions.

Core Areas

- Proton- and oxide-ion–conducting ceramic electrolytes (core)

Defect chemistry, hydration dynamics, and charge-transport mechanisms in perovskite and related oxides such as BaZrO₃ and BaSnO₃ derivatives. - Operando / in-situ scattering and spectroscopy (core)

Development and application of X-ray and neutron methods to observe structure and electronic states in working electrochemical systems. - Electrochemical energy devices based on ceramics (core)

Structure–interface–performance correlations in fuel cells, electrolyzers, and solid-state batteries using ceramic electrodes and electrolytes.

Emerging and Cross-Cutting Directions

- Photoelectrochemical materials and interfaces (emerging)

Semiconductor and oxide photoelectrodes, charge-carrier dynamics, and light-driven reactions for H₂, CO₂, and N₂ conversion. - Hybrid inorganic–biological assemblies (emerging)

Bio-photoelectrochemical architectures that couple biological components with inorganic semiconductors for new forms of energy conversion. - Gas-sensor and nanostructured oxide materials (complementary)

Morphology, defect states, and transport relationships in metal-oxide nanoparticle sensors. - Pattern formation, self-organization, and morphology control (cross-cutting)

Structural ordering and strain engineering to tailor transport and reaction pathways in ceramic architectures. - Quantitative modeling and data analysis (cross-cutting)

Mathematical and computational approaches supporting interpretation of complex operando datasets and design of functional materials.

Global Collaboration and Capacity Building

Our group maintains a long-standing international network that spans Europe, the United States, Asia, and Africa. Artur Braun’s scientific career itself bridges continents: after research appointments at Lawrence Berkeley National Laboratory (California) and the University of Kentucky, he joined Empa through a Marie Curie Re-Integration Grant from the USA to Switzerland. Subsequent sabbaticals at the University of Hawai‘i at Mānoa (USA), Yonsei University (Korea), and the Weizmann Institute of Science (Israel) further strengthened collaborative ties.

Bilateral projects with partners in Belgium, Ethiopia, Hungary, India, Israel, Korea, Lithuania, the Philippines, Poland, and South Africa have enabled joint research, student exchange, and mentorship—contributing to human-capacity building in materials science and electrochemistry. The group has co-organized more than twenty international symposia, workshops, and conferences in Europe and the USA on energy materials and operando characterization, and has represented user boards at major synchrotron and neutron facilities—PSI Villigen, ALS Berkeley, and ESUO. Many former collaborators and students of the group now hold faculty and research positions worldwide.

Our Research Topics

News

- October 2025 — Artur Braun and Lebogang Kotsedi secure a research grant for collaboration between Empa and iThemba LABS in South Africa on semiconductor photoelectrochemistry.

- October 2025 — Artur Braun and Igor Lubomirsky secure a research grant for collaboration between Empa and the Weizmann Institute of Science on ceramic proton conductors.

- October 2025 — We congratulate Glennise F. Mejica (University of the Philippines Diliman) for winning the ERDT Fellowship to visit Empa in 2025/2026 for PhD research on electrosynthesis of ammonia.

- September 2025 — We welcome Mr. Mun Jinwook from Yonsei University’s Ryu Group / BMES Lab for Bio-PEC experiments.

- September 2025 — New paper *Cover Story* published on operando NRVS of LiFePO4 batteries: Lattice Dynamics of Phase Transformations in LFP via 57Fe Nuclear Resonance Vibrational Spectroscopy and Atomistic Modeling, Crystals 15(10) 841. DOI 10.3390/cryst15100841.

- July 2025 — New paper accepted: Resilience of Hybrid Bioelectrodes in an Ionizing Environment: A Space Simulation Study of Limnospira indica Under Gamma Radiation, Astrobiology 25(8). DOI 10.1177/15311074251365212.

- April 2025 — New paper on NRVS of proton conductors: Phonon Density of States in Proton-Conducting Ceramics Probed by 119Sn Nuclear Resonance Vibrational Spectroscopy, Crystals 15(5) 440. DOI 10.3390/cryst15050440.

- March 2025 — New paper: Operando X-ray Raman Spectroscopy of a Working Lithium-Ion Battery, MRS Energy Advances. DOI 10.1557/s43580-025-01397-3.

- March 2025 — Media coverage by SRF1 Wissenschaftsmagazin (18:50–20:50) of our cyanobacteria campaign at Jungfraujoch.

- March 2025 — Artur Braun elected to the MRS Fellows Class of 2025.

- March 2025 — We welcome Physics Professor Dr. Selma Erat (Mersin University) for her SNF Research Visit.

- January 2025 — We welcome project collaborators Prof. Joey Ocon and Dr. DJ Matienzo (UP Diliman) for their project visit.

- January 2025 — New paper accepted with Qianli Chen’s group and colleagues from Korea, USA, and France on ambient-pressure XPS of proton conductors (ACS Applied Materials & Interfaces).

- December 2024 — We congratulate PhD student Kidan G. Gebremariam for her L’Oréal-UNESCO 2024 Award.

- September 2024 — We welcome Ethiopian physicist and ESKAS Fellow PhD student Kidan G. Gebremariam to the group.

- August 2024 — New paper published: “Restructurable materials for soft actuators,” Q. Chen (Invited Feature Paper — MRS Distinguished Invited Speaker), Journal of Materials Research. DOI 10.1557/s43578-024-01423-4.

- August 2024 — New paper published: “Fluorescence and electron transfer of Limnospira indica functionalized biophotoelectrodes,” Photosynthesis Research. DOI 10.1007/s11120-024-01114-5.

- July 2024 — 2nd edition of Artur Braun’s book published: X-Ray Studies on Electrochemical Systems — Synchrotron Methods for Energy Materials. DOI 10.1515/9783110794038.

- July 2024 — New paper published: “Electric Polarization-Dependent Absorption and Photocurrent Generation in Limnospira indica Immobilized on Boron-Doped Diamond,” ACS Omega. DOI 10.1021/acsomega.4c03925.

- May 2024 — New paper published: “Hygro-Dynamic and Conductive Actuator That Restructures and Heals by Water,” Advanced Functional Materials. DOI 10.1002/adfm.202402924.

- May 2024 — PhD student Kidan G. Gebreegziabher (Addis Ababa University) selected for the Swiss Government Excellence Scholarship 2023–2024; she will research in Braun’s group at Empa from 1 September 2024 to 31 August 2025.

- April 2024 — Braun and Profs. Danielle Mai (Stanford), Minkyu Kim (University of Arizona), and Newaye Tegegne (Addis Ababa University) organize the symposium “Bio-based and Biomimetic Polymers in Soft Robotics” at the MRS Spring Meeting 2024 (Seattle). Best Poster Award news. This symposium is inspired by the COgITOR project.

- 11 February 2024 — We welcome “returning” Visiting Professor Joey D. Ocon (UP Diliman), who begins his second stay at Empa.

- 11 February 2024 — We welcome Professor Julie Anne Del Rosario Paraggua (UP Diliman), who will stay for one week and deliver the seminar “Levelized cost of hydrogen produced via solar- and wind-powered electrolysis in the Philippines.”

- 1 February 2024 — We welcome PhD student Ms. Glennise Faye Mejica (UP Diliman), who will research for two months on photoelectrochemical ammonia synthesis funded by the Swiss–ASEAN project “Aurora.”

- 23 November 2023 — Dr. Nikolay Ryzhkov visits UP Diliman and presents “Bio- and biomimicking interfaces for smart materials design and alternative energy harvesting.”

- 7 October 2023 — Artur Braun experiences rocket attacks during his sabbatical at the Weizmann Institute of Science, Rehovot, Israel.

- 28 September 2023 — Manuscript accepted by Advanced Science (Wiley, IF 17): “Entropy and Isokinetic Temperature in Fast Ion Transport,” by Du, Peng; Zhu, Hong; Braun, Artur; Yelon, Arthur; Chen, Qianli.

- 15 September 2023 — Dr. Kwanele Kunene and Dr. Loghman Jamilpanah interview each other for the COgITOR project.

- 30 August 2023 — We congratulate our ESKAS Fellow Dr. Kwanele Kunene on her new position at Chalmers University (Sweden).

- 18 July 2023 — NCSU Professor Michael F. Dickey visits our lab and delivers a seminar (sponsored by EU COgITOR project).

- 9–13 July 2023 — Prof. Joey Ocon and Dr. Donn Matienzo visit our lab and deliver a seminar (sponsored by ASEAN “Aurora” project).

- 23 May 2023 — ASU Battery Professor Candace Chan visits our lab and delivers a seminar (sponsored by EU OpMetBat project).

- May 2023 — PhD student and postdoc, now Professor Debajeet K. Bora (Morocco), appears on German ZDF TV about solar hydrogen and climate: Planet e.: Zukunftsenergie Wasserstoff.

Projects & Funding Agencies

| Project Akronym | Description | Logo | Period |

|---|---|---|---|

| Effect of magnetic spin structure on photoelectrode transport properties of CuFe2O4 | 2025-2028 | ||

| Structure and dynamics of proton incorporation in ceramics | 2025-2029 | ||

| HYMETBAT | Hybrid metrology for sustainable and low-carbon footprint battery materials | 2025-2028 | |

| Kidan Gebremariam | ESKAS project on organic solar cells with Ethiopia | 2024-2025 | |

| SHINE |

Solar Harvesting and Integration to Photoelectrochemical Cell for Nitrogen Economy; with Univ. of the Philippines Diliman, Prof. Joey Ocon |

2024-2025 | |

| 3DCyan |

3D Printed Algal Biophotoelectrochemical Reactor For PV And Solar Fuel Production |

|

2023-2026 |

| Aurora | Renewable Ammonia with Univ. of the Philippines Diliman, Prof. Joey Ocon | 2023 | |

| OpMetBat |

Operando metrology for energy storage materials |

2022 - 2025 | |

| HySPARC | Sustainable hydrogen production in space by radiation hard cyanobacterial biofilms in photoelectrochemical system using B-doped diamond electrodes |  |

2022 - 2025 |

| COgITOR |

A new colloidal cybernetic system towards 2030 |

|

2021 - 2025 |

| Kwanele Kunene | ESKAS project on Electrosynthesis of Ammonia (South Africa) | 2022 - 2023 | |

| PROTONIQUE 3 |

Proton conductivity in epitaxial strained thin films |

2021 - 2025 | |

| PHOGAM |

Flanders/Swiss Lead Agency Process: Charge and energy transfer between cyanobacteria and semiconductor electrodes under gamma-irradiation |

|

|

| SUNRISE | Solar Energy for a Circular Economy | 2019-2020 | |

| Yonsei | Electrochemistry of the thylakoid membrane - metal oxide electrode assemblies | 2017 | |

| GIST |

SNF Korean Swiss project: Molecular and physical aspects of dye sensitization of photoelec-trodes with copper-based sensitizer molecules |

||

| SSAJRP | Production of Liquid Solar Fuels from CO2 and Water: Using Renewable Energy Resources | ||

| Pattern Formation for PEC | Reaction-diffusion processes for the growth of patterned structures and architectures: A bottom-up approach for photoelectrochemical electrodes | ||

| PEC EPFL | Defects in bulk and on surfaces and interfaces of metal oxides with photoelectrochemical properties: In-situ photoelectrochemical and resonant x-ray and electron spectroscopy | ||

| NANOPEC | Nanostructured Photoelectrodes for Energy Conversion | ||

| SOFC-Life | Solid Oxide Fuel Cells – Integrating Degradation Effects into Lifetime Prediction Models | ||

| MetInsTra | X-ray and electrochemical studies on solid Oxide fuel cells and related materials | ||

| HITEMPECHEM | X-ray and electrochemical studies on solid Oxide fuel cells and related materials |

Organized Conferences, Symposia & Workshops

Symposia, Conferences, and Workshops Organized

Selected international scientific events co-organized or chaired by Artur Braun and collaborators.

| Year | Role | Event | Participants | Location |

|---|---|---|---|---|

| 2025 | Co-Organizer (with E. Rozhkova, Q. Chen, W. Ryu) | MRS Spring Meeting Symposium “Protons in Solids, Fluids, and Molecules” | – | Seattle, USA |

| 2024 | Co-Organizer (with M. Kim, D. Mai, N. Tegegne) | MRS Spring Meeting Symposium “Bio-Inspired Soft Robotics” | ≈300 | Seattle, USA |

| 2023 | Area Coordinator (with G. Beck) | EUROMAT H: Materials for Circularity and Sustainability | ≈1000 | Frankfurt, Germany |

| 2021 | Co-Organizer (with N. Gaillard, E. Rozhkova) | PACIFICHEM Symposium “Artificial Photosynthesis” | ≈150 | Honolulu, Hawai‘i USA |

| 2019 | Lead-Organizer (with R. Toth) | SUNRISE Flagship Stakeholder Workshop | ≈30 | Empa, Switzerland |

| 2017 | Co-Organizer (with M. Diale) | MRS Fall Meeting Symposium | – | Boston MA, USA |

| 2017 | Co-Organizer | ALS User Meeting Workshop “Synchrotron Bio-Materials” | ≈30 | Berkeley CA, USA |

| 2015 | Co-Chair (with H. Fan, K. Haenen, L. Stanciu, J. Theil) | MRS Spring Meeting 2015 | ≈5500 | San Francisco CA, USA |

| 2015 | Lead Organizer | International Exploratory Workshop “PEC, Catalysis & X-ray” | ≈30 | Empa, Switzerland |

| 2013 | Lead Organizer | International Workshop “X-ray Electrochemistry” | ≈30 | Empa, Switzerland |

| 2013 | Co-Organizer (with A. Remhof) | ESS Science Symposium “Future Energy” | ≈40 | PSI Villigen, Switzerland |

| 2013 | Co-Organizer (with E. Rozhkova) | MRS Spring Meeting Symposium “Artificial Photosynthesis” | ≈100 | San Francisco CA, USA |

| 2012 | Co-Organizer | MRS Fall Meeting Symposium “Frontier Chemical Imaging” | ≈100 | Boston MA, USA |

| 2012 | Co-Organizer | MSE Symposium D4 “Thin Films” | ≈40 | Darmstadt, Germany |

| 2011 | Lead Organizer | MRS Spring Symposium “Protons in Solids” | ≈80 | San Francisco CA, USA |

| 2011 | Co-Organizer | E-MRS Spring Symposium “Materials for Solar Hydrogen” | ≈80 | Nice, France |

| 2010 | Lead Organizer (with C. Heske, M. Marcus, J. Guo) | MRS Spring Symposium “Diagnostics & Characterization of Energy Materials” | ≈100 | San Francisco CA, USA |

| 2010 | Lead Organizer (with C. Heske, M. Marcus, J. Guo) | ALS Users Meeting Workshop “Soft X-Ray Renewable Energy” | ≈25 | Berkeley CA, USA |

| 2009 | Lead Organizer (with P. Alivisatos, E. Figgemeier, J. Turner, J. Ye) | MRS Spring Symposium “Photoelectrochemistry for Environmental Applications and H₂ Generation” | ≈250 | San Francisco CA, USA |

| 2008 | Co-Organizer S. Erat | Empa PhD Symposium | – | St. Gallen, Switzerland |

| 2006 | Assistant Organizer (with P. Holtappels) | MODVAL-3 Workshop “Modeling & Validation of Fuel Cells” | ≈40 | Empa, Switzerland |

Presentations by Group Members, Visitors & Guests

| Name | Affiliation | Title | Conference | Place | Date |

|---|---|---|---|---|---|

| MSc Kidan Gebremariam | Empa, ETHZ and Addis Ababa University |

Charge carrier dynamics at the electron transport layer/organic interface in organic solar cells |

ESKAS Project | Empa, Dübendorf | 22 July 2025 |

| Dr. Paul J. Janssen | SCK CEN, Mol, Belgium | Sustainable, functional material on biobasis | PHOGAM Project | Empa, Dübendorf | 5 June 2024 |

| Dr. Qing Chen | Braun Group | The Design, Fabrication and Structural Modeling of Biomimetic Soft Materials for Robotic Applications | MRS Spring Meeting; COgITOR; Distinguished Invited Speaker | Seattle, WA, United States | 23 April 2024 |

| Dr. Qing Chen | Braun Group | A hierarchical fabriaction strategy for multi-responsive actuators and with structural reconfiguration-assisted self-healing avbility | DPG Tagung Berlin, invited talk (Hauptvortrag) | Berlin | 22 March 2024 |

| Assoc.-Prof. Julie Anne Paraggua | UP Diliman, Philippines |

Levelized cost of hydrogen produced via solar- and wind-powered electrolysis in the Philippines |

Empa Seminar | Empa, Dübendorf | 13 February 2024 |

| Dr. Nikolay Ryzhkov | Braun Group |

Bio- and biomimicking interfaces for smart materials design and alternative energy harvesting |

DChE Seminar | UP Diliman, Philippines | 23 November 2023 |

| MSc Nora Colson | Hasselt Univ., Braun Group | Welcome Presentation | Internal: ESA HySPARK Project | Empa Dübendorf | 1 September 2023 |

| Dr. Kwanele Kunene | Braun Group | Farewell Presentation of ESKAS Fellow | Internal: ESKAS Project | Empa Dübendorf | 30 August 2023 |

| Dr. Loghman Jamilpanah | Braun Group, Hug Group |

Developing Metallic Multilayers Hosting Different Skyrmion Types Toward Local Control via Electric Fields (Poster) |

13th Joint European Magnetic Symposia | Madrid, Spain | 29 August 2023 |

| Dr. Nikolay Ryzhkov | Braun Group |

Electric polarization effect on photosynthetic efficiency, non-photochemical quenching and photovoltaic performance of intact Limnospira indica based photoelectrodes |

20th Congress of the European Society for Photobiology |

Lyon, France |

28 August 2023 |

| Dr. Qing Chen | Braun Group |

Multi-sensing and self-healing skin for robotic applications |

ACS Fall Meeting 2023 | San Francisco, California | 16 August 2023 |

| Prof. Michael Dickey | North Carolina State University | Shaping a soft future | COgITOR project seminar | Empa Dübendorf | 19 July 2023 |

| Prof. Joey Ocon & Dr. DJ Donn Matienyo | University of The Philippines Diliman |

A Vertically Integrated Research Approach on Catalysis, Electrochemistry, and Energy Engineering |

Seminar of the ASEAN Aurora Ammonia Electrosynthesis project | Empa Dübendorf | 12 July 2023 |

| Prof. Candace Chan | Arizona State University |

Nanostructured Li7La3Zr2O12 Garnet Solid-State Electrolytes: Effect of Synthesis Route on Microstructure, Ionic Conductivity, and Lithium Stripping/Plating Behavior |

OpMetBat project semina | Dübendorf, Empa | 24 May 2023 |

| Dr. Artur Braun | Empa |

Parameterization of Proton Transport in Ceramic Electrolyte Membranes by Elastic Strain |

Colloquim 636 of the European Mechanical Society |

Besancon, France | 23 May 2023 |

| Dr. Qing Chen | Braun Group |

Investigation of strain-induced deformation of polymer thin films with small-angle X-ray scattering (SAXS) as a tool for microstructural study |

Colloquim 636 of the European Mechanical Society

|

Besancon, France | 22 May 2023 |

| Dr. Nikolay Ryzhkov | Braun Group |

Electric Polarization Effect on Photosynthetic Performance of Limnospira Immobilized at Diamond-like Carbon Electrodes |

35th Topical Meeting of the International Society of Electrochemistry |

Gold Coast, Australia | 9 May 2023 |

| Name | Position in Group | Current Position |

| Kidan Gebremariam | ESKAS Fellow | PhD Student, Addis Ababa University |

| Selma Erat | Visiting Professor | Professor, Mersin University |

| Loghman Jamilpanah | Postdoc Scientist | |

| Nora Colson | Visiting PhD Student | PhD Student, Hasselt Univ. |

| Glennise Faye Mejica | Visiting PhD Student | PhD Student, Univ. of the Philippines |

| Qing Chen | Scientist | Associate Professor, China Spallation Neutron Source |

| Yang Luo | Visiting Scientist | Professor, CU Hong Kong |

| Selma Erat | PhD Student ETHZ | Professor, Mersin University |

| Renata Solarska | Postdoc, Swiss BfE | Professor, Warsaw University |

| Debajeet K. Bora | PhD Student Uni Basel | Professor, Ben Guerir University, Morocco |

| Qianli Chen | PhD Student ETHZ | Professor, Shanghai Jiao Tong University, China |

|

Ramin Matloub Aghdam |

MSc Student KTH | PhD EPFL, Entrepreneur, PIEMACS Sarl, Lausanne |

| Kwanele Kunene | ESKAS Postdoc Fellow | Chalmers University, Sweden |

| Jean-Claude Tinguely | MSc Student FH Vorarlberg | PhD, Researcher at Tromso, University of the Arctic, Norway, |

| Jean-Pierre Pierog | MSc Student Univ. de Montpellier | ALSTOM, Engineer |

| Romy Löhnert | BSc Student Ernst Abbe hochschule Jena | PhD, Ernst Abbe Hochschule Jena |

| Dorota Flak | PhD Student AGH | Staff Scientist, Poznan University |

| Simon Tymen | MSc Student Univ. de Pau | PhD Berlin, Univ. de Nantes |

| Mateusz Schabikowski | MSc Student AGH | Adjunct, Polish Acad. of Sciences |

| Min-Kyu Son | Postdoc | Senior Researcher, KICET, Korea |

| Nikolett Nagy | BSc Student, Univ. of Szeged | MSc Univ. of Szeged |

| Krzysztof Szastak | MSc Student, AGH Krakow | Project Manager |

| Mahabubur Chowdhoury | Visiting Scientist, CPUT, Cape Town | Professor, CPUT, South Africa |

| Edvinas Navickas | PhD Student TU Wien | Infineon Technologies |

| Yelin Hu | PhD Student EPFL | BASF |

| Florent Boudoire | PhD Student Uni Basel | R&D Engineer CSEM, Neuchatel |

| Itani Madiba | PhD Student UNISA | Senior Researcher, Univ. of South Africa, Pretoria |

| Gareth-John Moore | MSc Student U Pretoria | PhD Uni Berne, RP Photonics AG |

| Kelebogile D. Mmabong | PhD Student U Pretoria | Senior Lecturer, Univ. of Botswana |

| Niels Burzan | MSc Student Uni Basel | PhD, CEO Mentix Schweiz GmbH |

| Gunnar Nurk | Scientist | Professor, Tartu University |

| Michel Prestat | Scientist | Senior Researcher, French Corrosion Institute |

| George Tsekouras | Postdoc | Research Fellow, Australian National University |

| Jianjun Wang | Postdoc | Professor, Shandong University |

| Tzu-Wen Huang | Postdoc | Sensor Industry, Switzerland |

| Alejandro Ovalle | Postdoc | Teaching |

| Rita Toth | Scientist | Coaching & Counseling |

| Songhak Yoon | Scientist | Staff Scientist, Fraunhofer IWKS |

| Krisztina Schrantz | Scientist, Asst.-Professor | Head EHSS, SOLVO Biotech |

| Santhi Ani Joseph | Professor | St. Teresa College, Ernakulam, Kerala, India |

We were delighted to have eminent scientists visiting our group:

|

U Philippines Diliman |

9 January 2025 |

|

|

SCK CEN - Belgian Nuclear Research Centre |

4 June 2024 |

|

|

North Carolina State University |

18 July 2023 |

|

|

Arizona State University |

24 May 2023 |

|

|

UCSF, San Francisco |

13 March 2019 |

|

|

Xi'an University |

20 August 2015 |

|

|

iThemba LABS |

|

|

|

Technion |

1 September 2015 |

|

|

Univ. of New South Wales |

|

|

|

Univ. of Tokyo |

|

|

|

University of Pretoria |

17-19 August 2015 |

|

|

KAIST, Korea |

17-19 August 2015 |

|

|

University of Bern |

17-19 August 2015 |

|

|

University of Pretoria |

17-19 August 2015 |

|

|

GIST, Korea |

17-19 August 2015 |

|

|

Universität Erlangen-Nürnberg |

17-19 August 2015 |

|

|

Stockholm University |

17-19 August 2015 |

|

|

University of Graz |

17-19 August 2015 |

|

|

Stanford University |

17-19 August 2015 |

|

|

SIMIT, Shanghai |

17-19 August 2015 |

|

|

Xi’an Jiaotong University |

17-19 August 2015 |

|

|

University of Tokyo |

17-19 August 2015 |

|

|

CPUT, Cape Town |

17-19 August 2015 |

|

|

Helmholtz Zentrum Berlin |

3-5 June 2013 |

|

|

Helmholtz Zentrum Berlin |

3-5 June 2013 |

|

|

PSI SLS and ETHZ |

3-5 June 2013 |

|

|

PSI SLS |

3-5 June 2013 |

|

|

TU Berlin and DESY FEL |

3-5 June 2013 |

|

|

Indian Institute of Science |

3-5 June 2013 |

|

|

SPECS GmbH, Berlin |

3-5 June 2013 |

|

|

EPFL |

3-5 June 2013 |

|

|

HZB Berlin |

3-5 June 2013 |

|

|

Gwangju Institute of Technology |

3-5 June 2013 |

|

|

SLS |

3-5 June 2013 |

|

|

Canadian Light Source |

3-5 June 2013 |

|

|

AGH Krakow |

3-5 June 2013 |

|

|

SLAC SSRL |

3-5 June 2013 |

|

|

PSI |

3-5 June 2013 |

|

|

McMaster University |

3-5 June 2013 |

|

|

LBNL Molecular Foundry |

3-5 June 2013 |

|

|

Dr. Matthew Brown |

ETHZ |

3-5 June 2013 |

|

LBNL ALS |

3-5 June 2013 |

|

|

NIMS |

2008 |

|

|

|

|

|

Nanopowders and ceramics

Our group explores the frontiers of high-entropy ceramics, advanced colloidal processing including light based 2PP/MPP and DLP shaping as well as FAST/rapid sintering techniques. We aim to develop materials with exceptional properties while using energy and resources in the most sustainable manner.

Our research emphasizes the intricate morphological, chemical, and crystallographic features of ceramic powders, materials, and composites. Moving beyond traditional parameters like density and grain size, we investigate the multidimensional design space and its influence on material performance. This approach enables us to push the boundaries of microstructure and grain boundary engineering, ultimately guiding the creation of next-generation ceramics with tailored properties.

We actively engage in R&D collaborations within national and international projects, partnering with both industry and academic institutions.

Synthesis of complex non-oxide ceramics

Advanced functional ceramics are key components in high-end applications ranging from large-scale technological applications in aerospace, transport, or energy to nanoscale electronics. Often subjected to extreme atmospheric conditions, these ceramics must maintain their structural and functional integrity at high temperature, in high vacuum, oxidizing atmosphere, corrosive media, and/or erosive flows. The broad family of electrically conductive non-oxide ceramics offers a wide range of functional and refractory properties that are tunable through their (micro)structural and compositional tailoring. However, the key challenge lies in achieving high phase purity.

Current research example: stabilizing atomically layered ternary ceramics through chemical complexity

Ternary carbide/nitride ceramics with the Mn+1AXn stoichiometry are known as MAX phases. The M is typically an early transition metal, A is an A-group element, and X denotes carbon and/or nitrogen. MAX phase ceramics have a layered crystal structure with distinct covalent and metallic bonding. Their hybrid structure results in a peculiar combination of material properties, some of which are metal-like (e.g., metallic luster, low hardness, plastic deformability, machinability using conventional tools), some of which typically ceramic (e.g., refractory, high strength and stiffness at high temperature, high resistance to thermal shocks, and chemically inert). Additionally, all elements in a MAX phase structure can form solid solutions, enabling virtually endless possibilities to tailor their structure and chemistry. However, MAX phase stability only exists in a small processing window, facing strong competition of binary carbide/nitride and intermetallic phases.

Our research focusses on the high-purity synthesis of MAX phase-based ceramics through structural stabilization, optimized feedstock (pre-)processing, and the use of advanced pressure-assisted reactive sintering techniques. Moreover, we explore the potential of high-entropy MAX phase ceramics through the controlled formation of chemically complex solid solutions to entropically stabilize the MAX phase.

Powder synthesis

Our expertise includes the synthesis of functional oxide nanoparticles - particularly via flame synthesis - along with their characterization and processing.

These powders can serve as fillers in polymer composites and coatings, as catalysts or as starting materials for advanced ceramic components. We place particular emphasis on particle characteristics such as shape, size, and phase, aiming to enable the development of materials with enhanced or novel properties. High-quality, engineered powders are essential for driving innovation and achieving optimal performance and added value in materials.

Current research example: synthesis of defected amorpheous silica to study their effect on the chemical and physical properties

Three-dimensional shaping of ceramics

Light-based ceramic 3D printing is among traditional precision shaping techniques another key focus of our group. We work across the entire process chain: from powder feedstock and slurry formulation to high-resolution shaping using Digital Light Processing (DLP) and two-/multi-photon polymerization (2PP/MPP).

Our research aims at addressing the main challenges in these technologies, including controlling light scattering in dense ceramic slurries, minimizing defects during printing, and achieving uniform densification in post-processing. By optimizing materials and processes, we aim to create complex ceramic components with enhanced microstructure, properties, and performance, pushing the boundaries of additive manufacturing.

Current research example: Selective Laser Sintering and Melting

Shaping of complex shaped, high precision and reliable parts as well as the long processing time and cost-intensive post processing is a key challenge in ceramics processing. Selective laser melting could be a solution of these problems. Although it is already a well-controlled and extensively used technology in the field of metals, alloys and polymers, key problems still have to be resolved for its use on brittle materials, and especially high performance ceramics.

The inability to closely monitor and fine tune the interaction of laser light sources with ceramic based powders remains a problem. Combined with the slow sintering kinetics of ceramics, a whole research field is left to explore. This highlights the current absence of industrial SLS processes to consolidate ceramic powders into dense structures with controlled material properties.

In our research, nanosized ceramic powders are granulated by spray drying to improve the powder handling especially from a flowability and safety point of view. Focus is put on maximizing the powder bed packing density and its influence on the solid and liquid phase sintering. Furthermore, the influence of the composition and morphology of these composite granules on the light absorption is studied, which in addition to minimizing thermal stresses and cracks is a key challenge for the future.

Ceramic based filters and membranes

Filters and membranes play an increasingly important role in technological breakthroughs, delivering environmental, societal, and economic benefits. Ceramic-based materials are particularly valuable in this field due to their exceptional heat and chemical resistance, as well as their structural stability.

Our research focuses on advanced microstructural control through careful powder selection and processing, combined with targeted doping and optimized sintering strategies. A special emphasis is placed on the controlled shaping of textured ceramic membranes, based on a technology developed for the shaping of precision ceramic medical devices for dermatological application (e.g., ceramic star structures), allowing to unite versatility and precision. By tailoring the microstructure and geometry at multiple scales, we aim to enhance performance, functionality, and durability in filtration and membrane technologies.

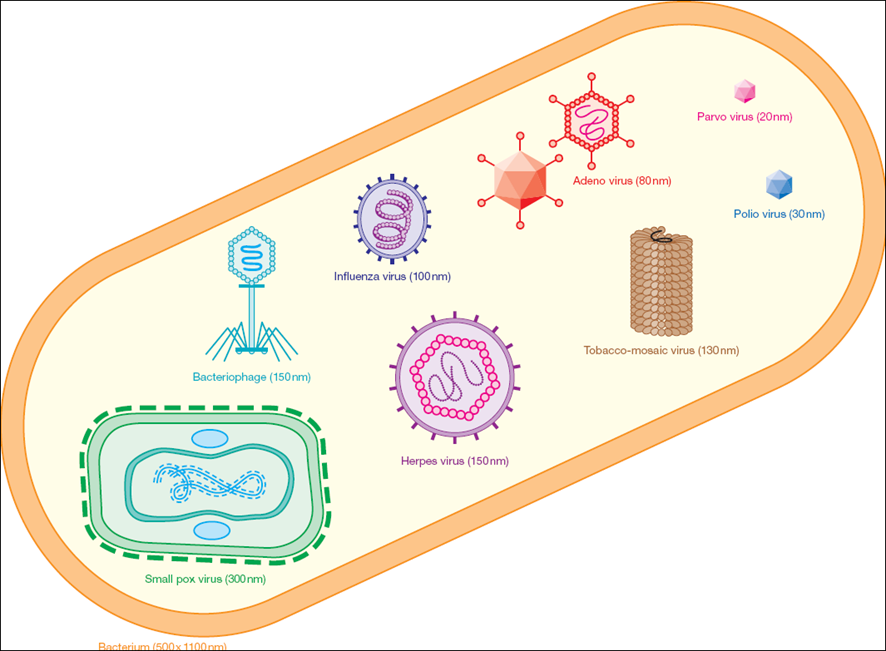

Current research example: Virus Filtration applying surface modified ceramics and carbon nanotubes

Water purification is necessary to prevent the spread of different diseases, caused by water-borne germs like bacteria, protozoa, and viruses. The germs may be separated from the water by a physical process, where the contaminated water is passing a porous medium like a filter or by adsorption driven separation processes. Our projects are focused on the adsorption based separation of viruses from water applying nanostructured, ceramic based filters as well as modified nanofibers originating from carbon nanotubes CNT and graphene. The biggest challenge results from the required filtering scale, namely the size of the viruses 20-50 times smaller than bacteria.

Recently we could evaluate the application of surface modified ceramic water filters for virus removal. Virus separation efficiencies (MS 2 bacteriophages and PhiX 174 bacteriophages ; size 25 nm, PZC 2 and 7 respectively) of 99 % to 99.99 % could be achieved. Such efficiencies being limited to narrow pH conditions more research is necessary to improve the systems to be compatible with common water sources. Modification of the highly active, porous ceramic surface was achieved by incorporation of nanosized inorganic particles.

As an alternative and promising solution for a broad pH spectrum, we apply CNT based fibers, after modification of the nanostructured surface.

Laboratory for High Performance Ceramics

|

Head of Laboratory Dr. Jakob Schwiedrzik |

||||||||

|---|---|---|---|---|---|---|---|---|

|

Assistance and Support Georgiana Schönberg |

||||||||

|

Ceramic based composites Dr. Gurdial Blugan |

Smart ceramic processing Dr. Frank Clemens |

Nanopowders and ceramics Dr. Michael Stuer |

Ceramic electrodes and electrolytes Dr. Artur Braun |

Architectured Materials Dr. Jakob Schwiedrzik |

||||

|

Scientists: Dr. Camila P. Canales Dipesh K. Dubey |

Scientists: Dr. Arun Ichangi Christopher Bascucci |

Scientists: Dr. Marc Brunet-Cabre

Annalena Erlacher

|

Scientists: Dr. Alexey Rulev

|

Scientists: Dr. Kevin Both Martina Birocco

|

||||

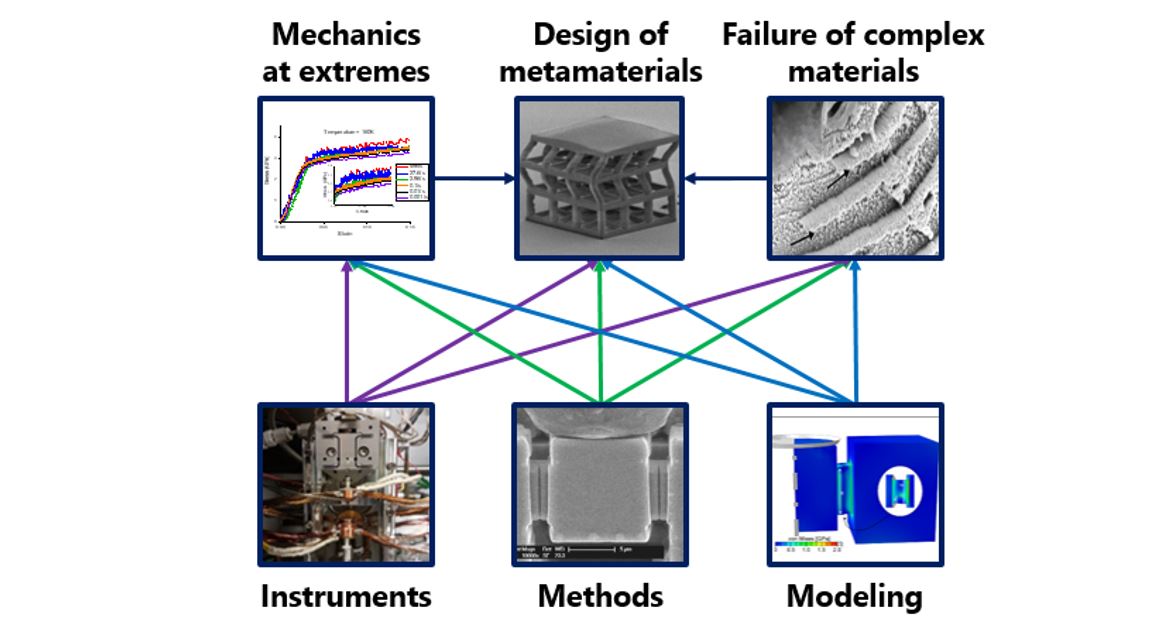

Architectured Materials

The Architectured Materials Group aims at developing novel ceramic-based materials that fill desirable white spaces in the Ashby diagrams and feature additional functionalities. We investigate fundamental processes of plasticity and fracture under extreme conditions and multiscale toughening mechanisms in complex hierarchical materials. We translate this knowledge into the design of novel porous ceramics, composites, and coatings with hierarchical architecture and tailored microstructure that allow us to combine usually mutually exclusive properties and functionalities. To achieve this, we actively develop scientific instruments and methods and closely integrate experimental and modeling approaches.

Fundamental processes of plasticity and failure in brittle materials

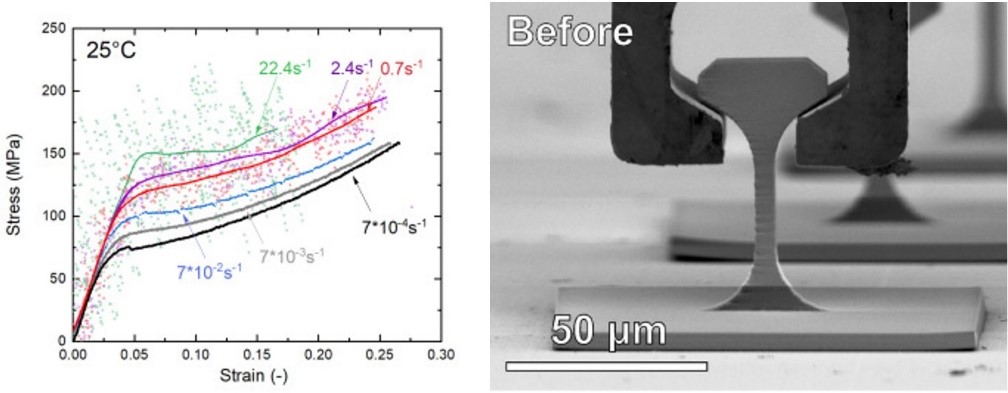

A potential pathway towards high specific strength materials is to make use of both extrinsic and intrinsic size effects. We investigate the fundamental processes of plasticity and fracture at the nanoscale and the effect of grain and component size on the mechanical behavior through a combination of thermal activation analysis, microstructural analysis, and computational modeling. A thorough understanding of the fundamental deformation and fracture mechanisms enables us to find pathways for in-fluencing the mechanical behavior of the material through microstructural design and architecture. To achieve this, we push the limits of what can be measured today through instrument and method devel-opment, e.g. for mode-dependent fracture, variable temperature, or high strain rate experiments. (Acta Materialia 2023, Materials & Design 2022, Materials & Design 2020, JMR 2019, Nano Letters 2019, FFEMS 2018)

Microtensile experiments as a function of strain rate on specimens prepared by 2 photon lithography (Materials & Design 2020)

Multiscale failure of hierarchical materials

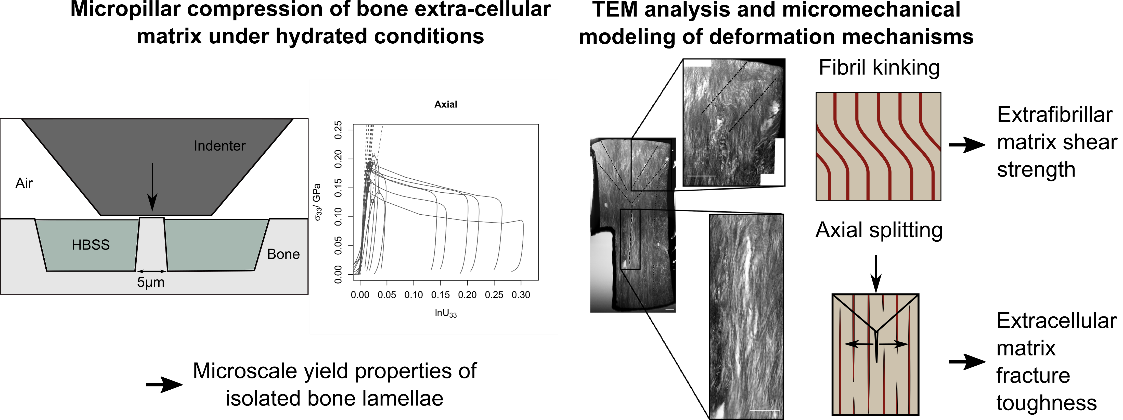

Furthermore, we study the failure of hierarchical materials such as biological nanocomposites to identify how these materials manage to combine toughness and strength with a light weight through multiscale toughening mechanisms. We assess the influence of their complex microstructure, i.e. the role of interfaces, defects, and material inhomogeneity, on their macroscopic failure behavior. Combining mechanical experiments, microstructural analysis, and mechanical modeling spanning from the nano- to the macroscale allows us to investigate and model the underlying physical processes at all relevant length scales. (Bone 2023, Acta Biomaterialia 2021, Acta Biomaterialia 2020, Acta Biomaterialia 2017, Nature Materials 2014)

Study on the deformation and failure mechanisms in lamellar bone through combination of micropillar compression, TEM imaging, and micromechanical modeling (Acta Biomaterialia 2017)

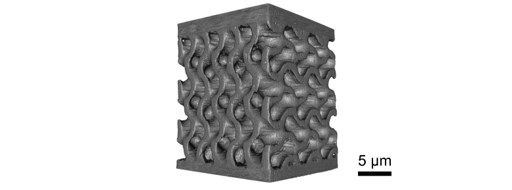

Design, synthesis, and characterization of architecture materials, composites and coatings

Based on the gained knowledge on fundamental processes at the nanoscale and multiscale toughening mechanisms, we develop novel ceramic-based materials that feature advantageous combinations of properties through simulation assisted design. This is achieved by making use of size effects, micro-structural design, and hierarchical architecture through a combination of diverse additive manufacturing and coating techniques such as lithographic and electrochemical methods to prepare materials with unique combinations of properties and functionalities. (Materials & Design 2020)

Smart ceramic processing

The focal point of the tasks lies in the interdisciplinary collaboration in the production of functional materials and composites. Developing prototypes of fibres, hollow fibers, foils and tubes is the main focus in the process development for developing novel system components.

> An overview of Smart Processing for Ceramics and Sensor-Composite Materials you find here:

Overview-PDF (982KB)

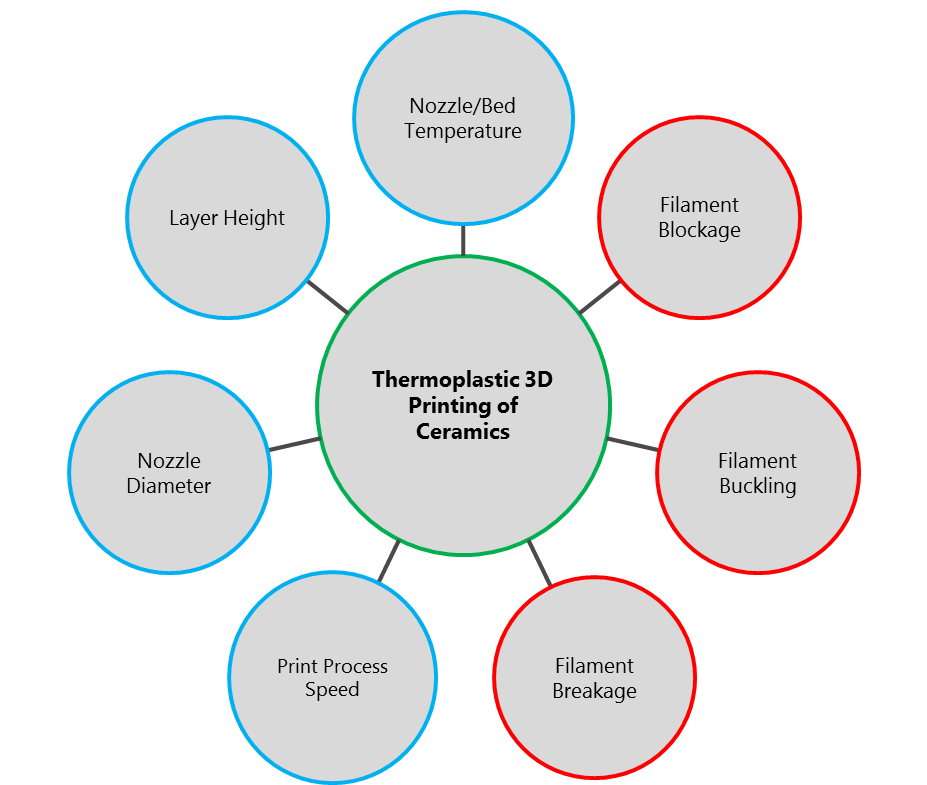

Thermoplastic forming Ceramics

The Laboratory for High Performance Ceramics is engaged in the development of thermoplastic forming and the development of thermoplastic binder systems for pressing, extrusion, injection molding, dip coating and 3D printing of ceramic components. Due to its many years of experience, the group does not focus on a specific binder system, but rather develops and optimizes customer-oriented, individual solutions. In the course of these developments, binder systems for the thermoplastic 3D printing of ceramic powders are also being developed. The additive manufacturing process of thermoplastic composites (Fused Deposition Modeling - FDM or Fused Filament Fabrication - FFF) is a recognized and widespread technology for the production of complex macroscopic structures. Empa develops thermoplastic binder systems, which enable cost-effective printing of ceramic components with conventional (open-source) FDM printers. Figure 1 shows the most important factors that influence the 3D printing of ceramics.

Figure 1: Typical factors influencing thermoplastic 3D printing of ceramic materials

blue = machine factors,

red = material failures

The 3D printing of thermoplastic ceramics offers the possibility to produce components individually via layered deposition. Typically, thermoplastic filaments are fed into a heated nozzle via a Bowden extruder. The polymer binder is melted and deposited in a desired position. After cooling and hardening, a structure with a layer thickness between 0.03 and 1.2 mm can built up.

The process is divided into several production steps:

- Compounding of the ceramic powder and the thermoplastic binder

- Filament or granule production for thermoplastic 3D printing

- 3D printing by melting the filament and layered deposition of the material

- Thermal treatment (debinding and sintering of the components)

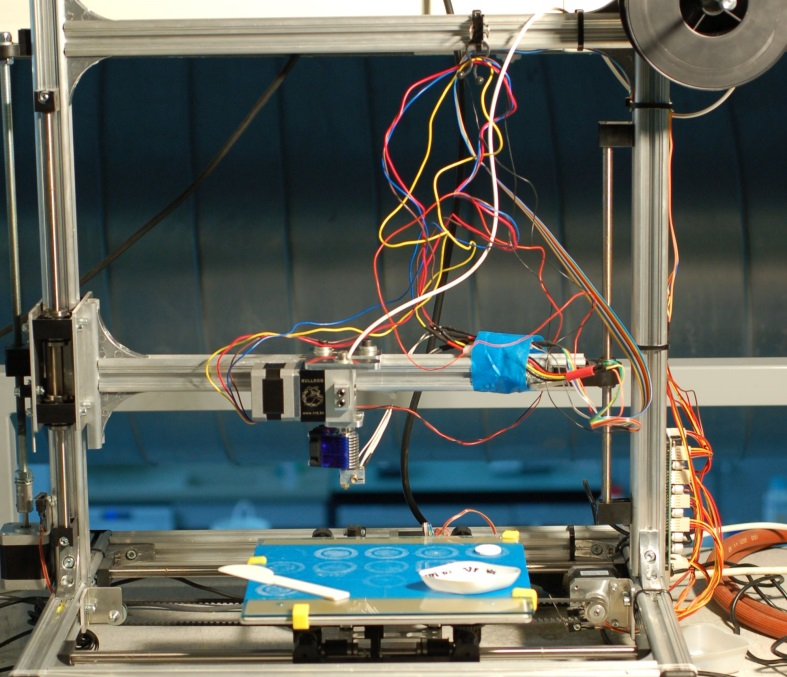

Post-treatment of the component surface can be done on the printed, debinded or sintered state. Figure 2 shows a commercially available simple 3D printer used for materials development.

Figure 2: Commercially available 3D printer for the development of thermoplastic ceramic materials.

Scientists:

Dr. Arun Ichangi

Dr. Elham Montakhab

PhD-Students:

Christopher Bascucci

Sofiia Butenko

visiting PhD-Student: