Nanopowders and ceramics

Our group explores the frontiers of high-entropy ceramics, advanced colloidal processing including light based 2PP/MPP and DLP shaping as well as FAST/rapid sintering techniques. We aim to develop materials with exceptional properties while using energy and resources in the most sustainable manner.

Our research emphasizes the intricate morphological, chemical, and crystallographic features of ceramic powders, materials, and composites. Moving beyond traditional parameters like density and grain size, we investigate the multidimensional design space and its influence on material performance. This approach enables us to push the boundaries of microstructure and grain boundary engineering, ultimately guiding the creation of next-generation ceramics with tailored properties.

We actively engage in R&D collaborations within national and international projects, partnering with both industry and academic institutions.

Synthesis of complex non-oxide ceramics

Advanced functional ceramics are key components in high-end applications ranging from large-scale technological applications in aerospace, transport, or energy to nanoscale electronics. Often subjected to extreme atmospheric conditions, these ceramics must maintain their structural and functional integrity at high temperature, in high vacuum, oxidizing atmosphere, corrosive media, and/or erosive flows. The broad family of electrically conductive non-oxide ceramics offers a wide range of functional and refractory properties that are tunable through their (micro)structural and compositional tailoring. However, the key challenge lies in achieving high phase purity.

Current research example: stabilizing atomically layered ternary ceramics through chemical complexity

Ternary carbide/nitride ceramics with the Mn+1AXn stoichiometry are known as MAX phases. The M is typically an early transition metal, A is an A-group element, and X denotes carbon and/or nitrogen. MAX phase ceramics have a layered crystal structure with distinct covalent and metallic bonding. Their hybrid structure results in a peculiar combination of material properties, some of which are metal-like (e.g., metallic luster, low hardness, plastic deformability, machinability using conventional tools), some of which typically ceramic (e.g., refractory, high strength and stiffness at high temperature, high resistance to thermal shocks, and chemically inert). Additionally, all elements in a MAX phase structure can form solid solutions, enabling virtually endless possibilities to tailor their structure and chemistry. However, MAX phase stability only exists in a small processing window, facing strong competition of binary carbide/nitride and intermetallic phases.

Our research focusses on the high-purity synthesis of MAX phase-based ceramics through structural stabilization, optimized feedstock (pre-)processing, and the use of advanced pressure-assisted reactive sintering techniques. Moreover, we explore the potential of high-entropy MAX phase ceramics through the controlled formation of chemically complex solid solutions to entropically stabilize the MAX phase.

Powder synthesis

Our expertise includes the synthesis of functional oxide nanoparticles - particularly via flame synthesis - along with their characterization and processing.

These powders can serve as fillers in polymer composites and coatings, as catalysts or as starting materials for advanced ceramic components. We place particular emphasis on particle characteristics such as shape, size, and phase, aiming to enable the development of materials with enhanced or novel properties. High-quality, engineered powders are essential for driving innovation and achieving optimal performance and added value in materials.

Current research example: synthesis of defected amorpheous silica to study their effect on the chemical and physical properties

Three-dimensional shaping of ceramics

Light-based ceramic 3D printing is among traditional precision shaping techniques another key focus of our group. We work across the entire process chain: from powder feedstock and slurry formulation to high-resolution shaping using Digital Light Processing (DLP) and two-/multi-photon polymerization (2PP/MPP).

Our research aims at addressing the main challenges in these technologies, including controlling light scattering in dense ceramic slurries, minimizing defects during printing, and achieving uniform densification in post-processing. By optimizing materials and processes, we aim to create complex ceramic components with enhanced microstructure, properties, and performance, pushing the boundaries of additive manufacturing.

Current research example: Selective Laser Sintering and Melting

Shaping of complex shaped, high precision and reliable parts as well as the long processing time and cost-intensive post processing is a key challenge in ceramics processing. Selective laser melting could be a solution of these problems. Although it is already a well-controlled and extensively used technology in the field of metals, alloys and polymers, key problems still have to be resolved for its use on brittle materials, and especially high performance ceramics.

The inability to closely monitor and fine tune the interaction of laser light sources with ceramic based powders remains a problem. Combined with the slow sintering kinetics of ceramics, a whole research field is left to explore. This highlights the current absence of industrial SLS processes to consolidate ceramic powders into dense structures with controlled material properties.

In our research, nanosized ceramic powders are granulated by spray drying to improve the powder handling especially from a flowability and safety point of view. Focus is put on maximizing the powder bed packing density and its influence on the solid and liquid phase sintering. Furthermore, the influence of the composition and morphology of these composite granules on the light absorption is studied, which in addition to minimizing thermal stresses and cracks is a key challenge for the future.

Ceramic based filters and membranes

Filters and membranes play an increasingly important role in technological breakthroughs, delivering environmental, societal, and economic benefits. Ceramic-based materials are particularly valuable in this field due to their exceptional heat and chemical resistance, as well as their structural stability.

Our research focuses on advanced microstructural control through careful powder selection and processing, combined with targeted doping and optimized sintering strategies. A special emphasis is placed on the controlled shaping of textured ceramic membranes, based on a technology developed for the shaping of precision ceramic medical devices for dermatological application (e.g., ceramic star structures), allowing to unite versatility and precision. By tailoring the microstructure and geometry at multiple scales, we aim to enhance performance, functionality, and durability in filtration and membrane technologies.

Current research example: Virus Filtration applying surface modified ceramics and carbon nanotubes

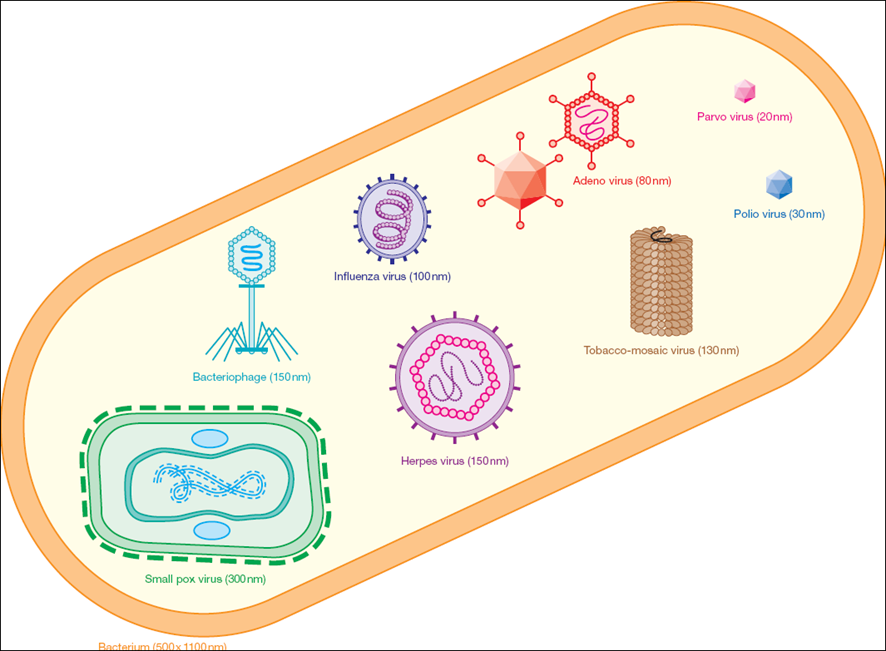

Water purification is necessary to prevent the spread of different diseases, caused by water-borne germs like bacteria, protozoa, and viruses. The germs may be separated from the water by a physical process, where the contaminated water is passing a porous medium like a filter or by adsorption driven separation processes. Our projects are focused on the adsorption based separation of viruses from water applying nanostructured, ceramic based filters as well as modified nanofibers originating from carbon nanotubes CNT and graphene. The biggest challenge results from the required filtering scale, namely the size of the viruses 20-50 times smaller than bacteria.

Recently we could evaluate the application of surface modified ceramic water filters for virus removal. Virus separation efficiencies (MS 2 bacteriophages and PhiX 174 bacteriophages ; size 25 nm, PZC 2 and 7 respectively) of 99 % to 99.99 % could be achieved. Such efficiencies being limited to narrow pH conditions more research is necessary to improve the systems to be compatible with common water sources. Modification of the highly active, porous ceramic surface was achieved by incorporation of nanosized inorganic particles.

As an alternative and promising solution for a broad pH spectrum, we apply CNT based fibers, after modification of the nanostructured surface.