Microstructural analysis

Microstructural analysis provides insight in the sequence of ASR and the products formed. Doping of concrete with caesium leads to its incorporation in the ASR products. This allows observing their formation in the scanning electron microscope from the initial state of the reaction due to the increased backscattering contrast (Figure 1).

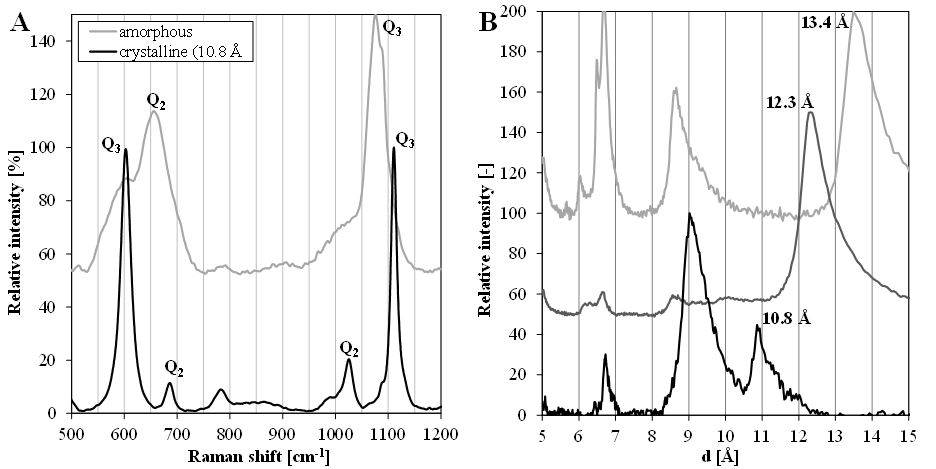

When larger amount of ASR products have formed with ongoing reaction, their composition can be analyzed with energy-dispersive X-ray spectroscopy. Raman microscopy provides insights in the structure of amorphous and crystalline ASR products (Figure 2A, link to Synthesis page). The extraction of samples in the range of a few micro-grams makes it possible to analyze them with capillary X-ray diffraction (XRD) (Figure 2B) or synchrotron-based µ-XRD.

Figure 2: Raman spectra of amorphous and crystalline (10.8 Å phase) ASR products (A) and the three crystalline ASR products with different d-spacing formed from ambient up to 40 °C (12.3 Å and 10.8 Å phase) and ≥ 60 °C (13.4 Å phase) analyzed by capillary XRD (B, link to X-ray center).

If larger samples can be extracted, their behavior in the presence of moisture can be investigated with dynamic vapor sorption. The application of micro-X-ray tomography as a non-destructive technique allows following the formation of both cracks and ASR products in 4D (link to tomography page). The complexity of ASR makes a multidisciplinary research approach necessary to improve the current knowledge (link to Webinar).

-

Share