Thin Film Deposition

Atomic & Molecular Layer Deposition

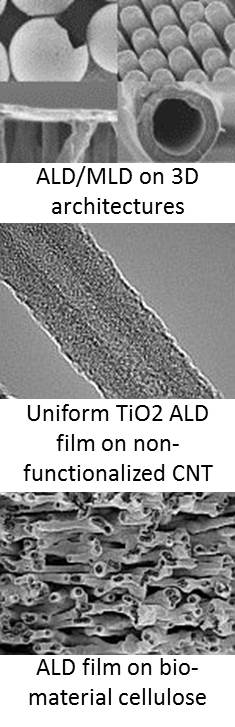

Examples of conformal ZnO/Al2O3 ALD films on 3D substrate architectures: polystyrene spheres, Si NWs, porous polycarbonate membranes.

ALD and MLD are essential thin film synthesis routes for nanoengineering. ALD & MLD rely on self-limiting surface reactions between the alternating gas precursors with a solid surface to deposit uniform ultrathin films with a subnanometer precision on geometrically complex nanostructures. We investigate ALD & MLD to develop:

• Novel concepts for conformal coatings of high-surface and heat sensitive materials.

• Nanolaminates for tuning materials properties and adhesion.

• Fundamental understanding of ALD & MLD precursor chemisorption and bonding on surface sites which will determine interfacial electrical and

mechanical properties.

• To design novel model materials for fundamental studies.

Constituent materials involve presently ZnO, TiO2, Y2O3, MnO, Al2O3, Al(Eg), and Al(Gl) while substrates span the wide range from oxides to metals to semiconductors having planar geometries or complex open-porosity three-dimensional architectures with applications in energy production and storage. The nanomaterials used in these supports include carbon nanotubes, graphene, nanowires and quantum dots.

Home-built ALD reactors

We have one commercial Arradiance reactor and three state of the art lab-built ALD & MLD reactors, with the possibility to be modified further for specific applications:

• A stationary reactor for the deposition of metal oxides. It also coats efficiently meso-porous materials with high specific surface area like aerogel or zeolite. This reactor can be modified to use plasma and/or ozone.

• A mobile-reactor reactor to connect to characterization equipment for in-situ studies.

• A commercial reactor with vapour push through option for low volatility precursors.

• An automated ALD-PVD (Mantis) system to deposit nanolaminates of metals and metal oxides without breaking vacuum.

Book chapter: C. Guerra, H. G. Park, I. Utke, ALD for interface engineering in: Atomic layer deposition in energy conversion applications. J. Bachmann, Wiley-VCH (2017) ISBN: 978-3-527-33912-9.

C. Guerra-Nunez, M. Dobeli, J. Michler, I. Utke, Reaction and Growth Mechanisms in Al2O3 deposited via Atomic Layer Deposition: Elucidating the Hydrogen Source, Chemistry Of Materials 29 (20) (2017) 8690-8703, DOI: 10.1021/acs.chemmater.7b02759.

Physical Vapour Deposition

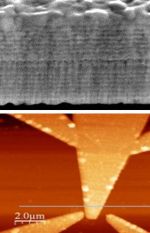

We develop physical vapour deposition for multilayer thin films with enhanced mechanical properties. Adapting the multilayer film thicknesses to characteristic dimensions associated to dislocation generation and cracking the materials properties can be tuned beyond the constituent materials. We also use resist based e-beam and UV lithography together with the in-built mini electron beam evaporator for conventional lift-off processing to prepare electrical contact pads for electronic nanodevices and solar cells.

-

Share