In-situ techniques

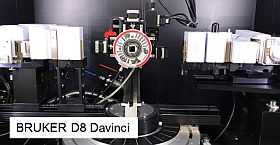

Temperature dependent XRD analyses:

RT ≤ T ≤ 1100°C

- Sample positioned on heating plate (AlN support)

- Application to thin films and bulk.

- Heating device: Anton Paar GmbH

RT ≤ T ≤ 800°C

- Local N2 heat stream.

- Application to single crystals and powders in caillaries.

- Heating device: Stoe & Cie

-150°C ≤ T ≤ 200°C

- Local N2 cooling / heat stream

- Application to single crystals and powders, liquids and suspensions in capillaries

- Cooling / Heating device: Oxford Cryosystems

Reactions on the XRD Instrument:

T ≤ 600°C

- Gas mixtures of N2, H2, NH3, C2H4 (atmospheric pressure, flow mode)

- Surface treatment with HCl

- Large (20 mm × 5 mm) sample size

- Applicable to Bruker D8, Panalytical X‘Pert

- Custom built by FH Bern/Empa

Mechanical stresses on the SAXS / WAXD instrument:

Stress-strain analysis

- Adaptable on Nanostar and Molmet systems

- Accessible 2Ɵmax=22°

- Application to membranes, fibers and thin films

- Tensile stage: Anton Paar GmbH

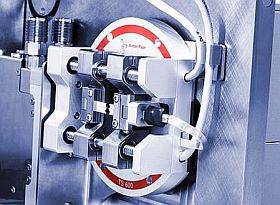

Fluidics on the SAXS instrument:

Fast dynamical studies ( <1s )

- Accessible qmin=0.04 nm-1

- Application to particle agglomeration in-vitro self-assemblies, biosynthesis and crystal nucleation and growth

- Equipped with four low pressure neMESYS pumps

Humidity studies on micro-CT and phase contrast-CT:

Climatic chamber:

- Relative humidity control

- Temperature range: ambient to 85°C

-

GenRH-Temperature and humidity generator

Mechanical stresses on nano-CT:

Deben CT5000-RT in-situ tensile stage:

- tensile and compression testing

- operating at room temperature

- Exchangeable load cells 500N, 2kN, 5kN

-

Share