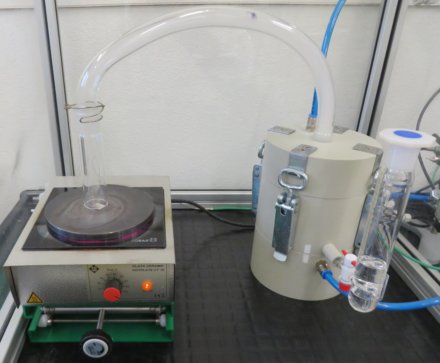

Thin films by aerosol-assisted chemical vapor deposition (AA-CVD)

Thin films are indispensable for a wide range of applications, not only as protective, but also as functional coatings. AA-CVD is a cost-effective chemical vapor deposition technique applying a simple, non-vacuum spray pyrolysis setup in open atmosphere (air). It allows reproducible deposition of homogeneous mixed metal oxide or noble metal thin films with controlled microstructures. As the thin film precursors are transported as an aerosol, requirements for volatility and temperature stability of the metal precursors are less stringent than for conventional CVD techniques, and constant film growth rates are assured. Depending on the application, the deposition conditions can be tuned to obtain granular (randomly oriented) or columnar (preferentially oriented) thin films with nano-porous or dense microstructures. Dense (Zr,Y)O2-δ and (Ce,Gd)O2-δ layers with good oxygen ion conductivity have successfully been applied as thin film electrolyte membranes and diffusion barrier layers for solid oxide fuel cells, while Pt, Ni, and cermet (e.g. Ni-YSZ) thin films show great potential to increase interfacial reactions at electrodes.

Platinum Thin-Film Electrodes: Adv. Eng. Mater., 2016.

Thin film SOFC membranes: Adv. Energy Mater., 2014, 4, 1301383.

Gadolinia doped ceria thin films: Fuel Cells, 2013, 13, 658-665.

Microstructure of yttria stabilized zirconia thin films: Adv. Energy Mater., 2013, 3, 375-385.

Growth of yttria stabilized thin films: J. Power Sources, 2012, 202, 47-55.

-

Share