Timber Engineering

At the Timber Engineering Group of the Structural Engineering Research Laboratory, we conduct experimental, analytical, and numerical research on topics with high potential to influence the development of timber and hybrid timber structures, aiming at improving their competitiveness, safety, serviceability, durability, robustness, and sustainability.

Our current research activities focus on:

- multi-storey buildings and complex structures – lateral force resisting systems, timber connections, structural robustness, and reliability of timber structural systems;

- design for extended service life and circularity;

- structural applications of hardwoods;

- development of structural design codes on national and European levels.

In our large testing hall, we perform research experiments and tests under ISO/IEC 17025 accreditation, including large-, medium- and small-scale quasi-static, fatigue, and dynamic tests.

Team

Ongoing research projects

"Think Earth – Regenerative Construction" Innosuisse Flagship

Experience from traditional building techniques with timber and earth is being further developed in a resource-saving and circular way. Subproject 7 creates innovative strategies in timber construction to enhance the reuse of components through advanced connections and digital tools. Connections are tested for disassembly and reuse, while digital tools such as augmented reality (AR) and digital twins streamline planning.

Funding: Innosuisse – Swiss Innovation Agency

Partners: ETH Zurich (Chair of Architecture and Digital Fabrication and Chair of Timber Structures), BFH (School of Architecture, Wood and Civil Engineering), OST Eastern Switzerland University of Applied Sciences, HSLU Lucerne School of Engineering and Architecture

RelyConnect – Reliable and high-performance modern timber structures with modern connections

Connections are a vital part of timber structures, and they are crucial in providing plasticity to the structure. Extensive research has been conducted on the load-carrying capacity of laterally loaded metallic fasteners in timber connections, but there is a lack of knowledge on their stiffness in the serviceability and ultimate limit states. A common design approach of assuming a connection stiffness K_SLS for the serviceability and K_ULS=(2/3)K_SLS for the ultimate limit states is based on research on connections that is no longer representative of modern timber connections but is nevertheless applied to all types of connections. Given their importance in distributing the loads and providing plasticity in timber structures, an approach that better reflects reality is necessary. In this project, the performance of timber connections comprising multiple fasteners is assessed based on existing experimental data, analytical and numerical modelling. Moreover, probabilistic modelling is conducted to ascertain the reliability of timber connections for multiple limit states.

Funding: Swiss National Science Foundation SNSF (Weave)

Partners: Lund University

Publications:

- Cao, A. S., S. Thöns, R. Jockwer, and P. Palma. 2025. “System effects in timber connections comprising multiple fasteners.” Proceedings of the 14th International Conference on Structural Safety and Reliability – ICOSSAR'25, 12. Los Angeles, USA. https://www.dora.lib4ri.ch/empa/islandora/object/empa%3A41637

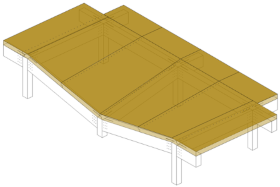

Preventing disproportionate collapse in tall timber buildings

The development of alternative load paths in timber post-and-beam buildings experiencing local damage, such as the loss of a load-bearing column, depends on the ability of the system to redistribute design loads and accommodate deformations. Limited research has examined how different components, particularly the interaction between the frame structure and the floor system, affect the system behaviour.

Due to the additional stiffness and ductility provided by the mechanical fasteners in the floor system, it likely plays a fundamental role in load redistribution under column removal scenarios. This study aims to assess the role of the floor system in developing alternative load paths and establish design methodologies to enhance structural response under such conditions.

Funding: Swiss National Science Foundation SNSF

Partners: ETH Zurich (Chair of Risk, Safety and Uncertainty Quantification and Chair of Timber Structures)

Publications:

- Felicita, M. P., J. Knuppe, K. Zutt, G. Ravenshorst, and M. Mirra. 2025. “Alternative load path analysis of timber post-and-beam modular buildings.” Proceedings of the World Conference on Timber Engineering 2025 – WCTE 2025. Brisbane, Australia. https://www.dora.lib4ri.ch/empa/islandora/object/empa%3A41771

Robustness of timber structures – Experimental characterisation of progressive collapse scenario

As the size and complexity of modern timber buildings grow, resistance to disproportionate collapse and robustness become key requirements in their structural design. A potential measure against progressive collapse after initial damage to a member due to, for example, vehicle impact is the provision of alternative load paths for load redistribution. In timber structures, connections are the critical components to allow load redistribution and ductility.

This project investigates commonly used steel-to-timber connections experimentally and numerically under a sudden column loss scenario. The capability for load redistribution of laterally-loaded dowelled connections with slotted-in steel plates will be assessed under large displacements and combined bending and tensile loading. The connections will be studied at quasi-static and high loading speeds to assess the dynamic effects of a sudden column loss. The objectives are to provide large-scale experimental data for the validation of numerical models, guidance on connection detailing for load redistribution, and guidance on the dynamic effects to be considered in robustness assessments.

Funding: Swiss National Science Foundation SNSF (COST)

Partners: ETH Zurich (Chair of Timber Structures)

Publications:

- Sroka, K., A. Sixie Cao, P. Palma, and A. Frangi. 2025. “Rate-dependency and hysteresis of timber connections with a single laterally-loaded dowel and a slotted-in steel plate.” Wood Material Science & Engineering, 0 (0): 1–21. Taylor & Francis. https://doi.org/10.1080/17480272.2025.2509102

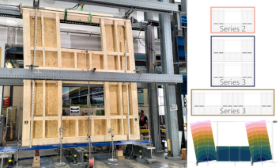

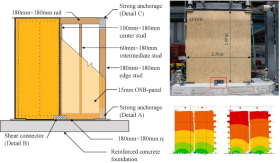

Experimental and numerical investigations of sheathed timber frame shear walls with large openings subjected to lateral loading

In timber buildings, the lateral force resisting system frequently is realized by means of sheathed timber frame shear walls. According to most standards for the design of timber structures, only those wall segments that are continuous from the floor slab up to the top edge of the building may be taken into account to contribute to the lateral load-resisting system. However, in modern architecture, many buildings consist of walls with numerous, sometimes large openings. As a result of this trend, only relying on the wall parts without openings is often not sufficient for ensuring the horizontal structural stiffness of the building. Another major disadvantage when neglecting walls with openings in the lateral load-resisting system is the resulting increased forces in the anchorages. As shown schematically in the figure, fewer anchors would be needed and lower forces would have to be transferred, if the stiffening effect of wall segments with openings is taken into account.

The main objective of the project is to develop an experimentally validated method for the modelling, design and construction of timber frame shear walls with large openings that are assigned by the designer to contribute to the lateral load-resisting system.

Funding: Swiss Federal Office for the Environment (FOEN), Aktionsplan-Holz

Partners: BFH, Department of Architecture, Timber and Construction; ETH, Institute of Structural Engineering; Swiss Timber Engineers; Holzbau Schweiz; Ancotech AG

Publications:

- Manser N., Steiger R., Geiser M., Otti M., Frangi A. (2024). Shear resistance of Oriented Strand Board panel sheathings in timber-framed shear walls. Engineering Structures 316: 118461.

https://doi.org/10.1016/j.engstruct.2024.118461 - Manser N., Steiger R., Geiser M., Kramer L., Frangi A. 2023: Timber-framed shear walls with large openings as part of the lateral force-resisting system - Optimization of the sheathing-to-framing connection layout. Proceedings of World Conference on Timber Engineering WCTE, Oslo, Norway, June 19 – 22, 2023. 2686-2694.

https://doi.org/10.52202/069179-0352

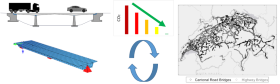

Fatigue behaviour of threaded rods glued into GLT for bridge construction

In the future, more road bridges with high life loads and high traffic volumes will be built in timber. However, there is still a lack of basic knowledge for the safe application of timber construction when designing heavily frequented bridges, particularly regarding the fatigue resistance in service class 2. The project contributed to filling this knowledge gap, hereby focusing on high-performance connections with bonded-in threaded rods. The project results help extending the range of application of timber road bridges involving connections with glued-in threaded rods by providing information for fatigue design regarding (i) the influence of wood moisture (service class 2), (ii) the influence of the angle between the axially loaded threaded rods and the grain direction of the wood (parallel & perpendicular to the grain), (iii) the influence of the wood species (European ash, Norway spruce).

Funding: Swiss Federal Office for the Environment (FOEN) and Cantons (Wald- und Holzforschungsförderung Schweiz WHFF-CH)

Partners: neue Holzbau AG

Publications:

- Steiger, R., Maurer, Kramer, L., B., Strahm, T., Gehri, E. (2025). Fatigue behaviour of threaded rods bonded into glulam for application in bridge construction. International Network on Timber Engineering Research (INTER) – 12th meeting. Istanbul, Turkey. https://holz.vaka.kit.edu/741.php

- Maurer, B., Gehri, E., Strahm, T., Steiger, R., & Affolter, C. (2022). Fatigue strength of axially loaded steel rods bonded in European ash glulam. In B. Franke & S. Franke (Eds.), Timber bridges. International Conference on Timber Bridges ICTB2021PLUS (pp. 223-230). Bern University of Applied Sciences.

https://www.dora.lib4ri.ch/empa/islandora/object/empa:31218

Swiss Center of Excellence on Net-Zero Emissions (SCENE): Action Area "Efficient Technical Cycles"

In a road bridge case study, solutions are developed for: reduction in the use of CO2-emitting materials (e.g. concrete, steel) through the use of advanced manufacturing processes and replacement with sustainable timber-based materials, by:

- changing materials chemistry and processing, and by storing carbon in construction materials

- material savings by using topologically optimized geometries for bridge components instead of conventional prismatic geometries

- use of digitally fabricated formworks, serving as permanent parts of the structure and allowing for complex geometries

- recycling of materials and reuse of components from torn-down structures as reinforcement, integrating them in newly built structures.

Funding: ETH Board

Partners: Empa (Structural Engineering Research Lab, Concrete & Asphalt Lab, and Technology & Society Lab), Eawag, PSI, WSL

Publications:

- Schmidt, T. J., Niesen, B., Whyte, C., Thürig, E., Malfait, W., Steiger, R., … Noukakis, D. (2024). Swiss Center of Excellence on Net-Zero Emissions (SCENE): Annual report 2023.

https://doi.org/10.55402/psi:66609

Timber crane runways

Timber crane runways are a new application for which high-performance hardwood elements are particularly well suited. The project addresses several issues arising from this new application. The behaviour of timber under compression perpendicular to the grain on the behaviour of a new rail system based on standard components is being studied, as well as the effects of different vibration absorbing interlayers. The results will the use of hardwood in other new high-performance applications. Sustainability aspects relating to the use of timber instead of steel for crane runways are also being investigated.

Funding: Federal Office for the Environment FOEN and Cantons (Wald- und Holzforschungsförderung Schweiz WHFF-CH)

Partners: Empa (Structural Engineering Research Lab, Acousitc Lab, Technology and Society Lan), n’H, GERSAG

Finalised research projects

Shear strength and stiffness of glued-laminated timber made from hardwood

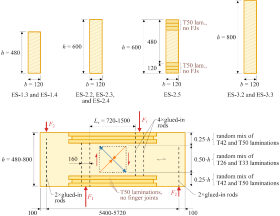

The influence of size effects on the shear strength and stiffness of glued-laminated timber (GLT) made from European ash (Fraxinus excelsior L.) was assessed based on a comprehensive experimental campaign. The experiments were performed on full-scale GLT beams with cross-sections up to h=0.800 m and lengths up to L=5.720 m. The innovative asymmetric 4-point bending test configuration allowed testing shear fields with different shapes and realistic structural dimensions. The results showed the influence of size effects on the shear strength and led to the proposal of structural design rules.

Funding: Federal Office for the Environment FOEN and Cantons (Wald- und Holzforschungsförderung Schweiz WHFF-CH)

Partners: n’H

Publications:

- Palma, P., R. Steiger, T. Strahm, and E. Gehri. (2025). “Shear strength and stiffness of glued-laminated timber made from European ash (Fraxinus excelsior L.).” Eur. J. Wood Prod., 83 (5): 1–14.

https://doi.org/10.1007/s00107-025-02296-y. - Palma, P., R. Steiger, T. Strahm, and E. Gehri. 2022. “Shear stiffness and strength of European ash glued laminated timber.” International Network on Timber Engineering Research (INTER) – Meeting Fifty-five, 225–241. Bad Aibling, Germany: Timber Scientific Publishing.

https://www.dora.lib4ri.ch/empa/islandora/object/empa%3A32278 - Gehri, E., R. Steiger, P. Palma, and T. Strahm. 2022. Festlegung der Schubsteifigkeit und Schubfestigkeit von Trägern, insb. aus Laubholz-BSH. 155. Switzerland: Empa – Swiss Federal Laboratories for Materials Science and Technology.

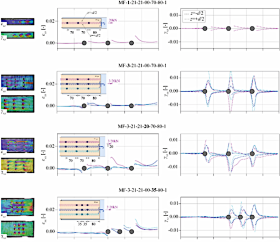

Structural behaviour and reliability of connections in timber structures

The aim of this research project was to study the global behaviour and reliability of timber structures, taking into the account the behaviour and reliability of its members and connections. The part of the project carried out at Empa focused on developing a modelling framework for simulating the load-deformation behaviour and load-carrying capacity of dowelled steel-to-timber connections under non-eccentric and eccentric axial loading. The approach comprised a model to simulate the load-deformation behaviour and load distribution within the connection, based on the load-deformation behaviour of individual dowels, and a model to calculate the stresses within the timber matrix of the connection. The developed modelling framework was calibrated and validated based on an extensive and comprehensive multi-scale experimental campaign, which included experiments at the material, single-fastener, and connection level.

Funding: Swiss National Science Foundation SNSF

Partners: ETH Zürich (Chair of Timber Structures)

Publications:

- Palma, P., and J. Wydler. 2025. “Dataset with results of multi-scale experiments on timber connections.” Zenodo. https://zenodo.org/records/14870762

- Wydler, J. 2023. “Stress-Based Failure Model for Dowelled Steel-to-Timber Connections under Eccentric Loading.” Doctoral Thesis. ETH Zurich.

https://doi.org/10.3929/ethz-b-000599768 - Schilling, P., N. Manser, P. Palma, R. Steiger, and A. Frangi. 2022. “Design of timber trusses with dowelled steel-to-timber connections.” International Network on Timber Engineering Research (INTER) – Meeting Fifty-five, 285–299. Bad Aibling, Germany: KIT Scientific Publishing.

https://www.dora.lib4ri.ch/empa/islandora/object/empa%3A26917 - Schilling, P., P. Palma, R. Steiger, and A. Frangi. 2021. “Probabilistic description of the mechanical properties of glued laminated timber made from softwood.” International Network on Timber Engineering Research (INTER) – Meeting Fifty-four, 333–348. Online. https://www.dora.lib4ri.ch/empa/islandora/object/empa%3A26917

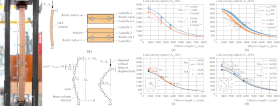

Steel-reinforced columns made of European beech glued-laminated timber

One of the obstacles to the recent trend toward taller timber buildings is the limited load-carrying capacity of softwood columns. With the aim of promoting the structural use of European beechwood (Fagus sylvatica L.) in high-performance applications, the buckling behaviour of beech glued-laminated timber (GLT) columns reinforced with glued-in steel bars was investigated experimentally and numerically. Buckling experiments were carried out on full-scale columns and a finite-element model was developed. The experimental and numerical data demonstrate the high potential of this new structural product for high-strength columns in demanding residential, office, and industrial applications. The glued-in steel reinforcement is also expected to be able to provide an alternative load path for structural robustness, by enabling the columns to carry tensile forces. A design method for corner-reinforced beech GLT columns under axial compression was developed based on the empirical and numerical data.

Funding: n’H

Partners: n’H

Publications:

- Sroka, K., P. Palma, R. Steiger, T. Strahm, and E. Gehri. 2024. “Steel-reinforced columns made of European beech glued-laminated timber.” J. Struct. Eng., 2 (150): 04023228. American Society of Civil Engineers.

https://doi.org/10.1061/JSENDH.STENG-12709. - Sroka, K., P. Palma, R. Steiger, T. Ehrhart, A. Frangi, T. Strahm, and E. Gehri. 2023. “Unreinforced and steel-reinforced columns made of European beech glued-laminated timber.” Proceedings of the 2023 World Conference on Timber Engineering (WCTE 2023), 315–322. Oslo, Norway.

https://doi.org/10.52202/069179-0043

Glued laminated timber made of European beech wood

This project aimed at promoting the use of beech wood for the production of glued-laminated timber of strength classes GL40, GL48 and GL55. Main prerequisites for the design of structural elements (preferably beams and columns in service class 1) are appropriate production technologies, quality control of raw material and final product, as well as knowledge of mechanical properties (bending and shear stiffness and strength, tension and compression strength parallel to the grain, compression strength perpendicular to the grain). Starting from the raw material supply (origin, sawing pattern, drying process, strength grading) all further steps in production (finger jointing, surface gluing of lamellas) as well as the properties (strength and stiffness) of the final product were investigated.

Funding: Federal Office for the Environment FOEN (Aktionsplan Holz)

Partners: ETH Zürich, Institute of Structural Engineering IBK; Bern University of Applied Sciences; neue Holzbau AG; Corbat Holding SA; Richard Lötscher AG; Konrad Keller AG; Koller Sägerei AG; Holzindustrie Schweiz

Publications:

- Ehrhart T., Palma P., Schubert M., Steiger R., Frangi A. (2022). Predicting the strength of European beech (Fagus sylvatica L.) boards using image‑based local fibre direction data. Wood Science and Technology 56: 123 − 146.

https://doi.org/10.1007/s00226-021-01347-w - Ehrhart T., Steiger R., Frangi A. (2021). Brettschichtholz aus Buche. Bautechnik 98: 104 − 114.

https://doi.org/10.1002/bate.202100016 - Ehrhart T., Steiger R., Palma P., Gehri E., Frangi A. (2020). Glulam columns made of European beech timber: compressive strength and stiffness parallel to the grain, buckling resistance and adaptation of the effective-length method according to Eurocode 5. Materials and Structures 53: 91.

https://doi.org/10.1617/s11527-020-01524-6 - Ehrhart T., Steiger R., Lehmann M., Frangi A. (2020). European beech (Fagus sylvatica L.) glued laminated timber: lamination strength grading, production and mechanical properties. European Journal of Wood and Wood Products 78: 971 − 984. https://doi.org/10.1007/s00107-020-01545-6

- Ehrhart T., Steiger R., Frangi A. (2017). A non-contact method for the determination of fibre direction of Euro-pean beech wood (Fagus sylvatica L.). European Journal of Wood and Wood Products 76 (3):925 – 935.

https://doi.org/10.1007/s00107-017-1279-3

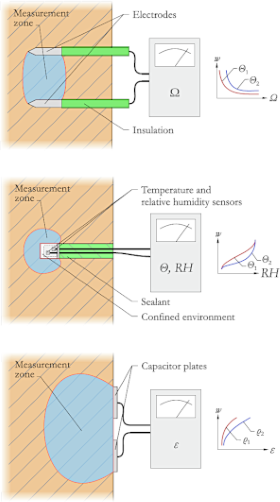

Structural health monitoring of timber structures

The aim of this project is to give an overview of available structural health monitoring (SHM) strategies for timber structures and describe the used methods and technologies. Monitoring strategies will be analysed taking into account specific aspects of the behaviour of timber structures (e.g. anisotropy, high variability, moisture and temperature dependency, low stiffness, duration of load effects, and creep). The operational aspects of the monitoring strategies (what is monitored and how the monitoring is carried out), and data acquisition aspects (excitation methods, sensor type, number and locations, and the data acquisition, transmission, and storage equipment) will also be analysed.

Funding: Federal Office for the Environment FOEN and Cantons (Wald- und Holzforschungsförderung Schweiz WHFF-CH)

Partners: Schilliger Holzindustrie AG

Publications:

- Palma, P., and R. Steiger. 2020. “Structural health monitoring of timber structures – Review of available methods and case studies.” Construction and Building Materials, 248: 118528.

https://doi.org/10.1016/j.conbuildmat.2020.118528. - Palma, P., and R. Steiger. 2018. Structural health monitoring of timber structures – review of available methods and case studies. 56. Dübendorf, Switzerland: Empa - Swiss Federal Laboratories for Materials Science and Technology.

Earthquake resistant timber structures for multi-story buildings

The project focused on the behavior of joints and wall elements in multi-story wooden structures during moderate earthquakes and strong winds. Using a deformation-based design method, the structure was optimized for low to medium seismicity and moderate wind action prevailing in Switzerland. Experiments were performed on OSB-sheathed light-frame timber shear walls subjected to quasi-static monotonic and cyclic loading, with simultaneously acting vertical force and bending moment, and numerical simulations were set up for parametric studies. Adapted loading protocols for cyclical tests of joints and wall elements were developed. Compared to protocols for areas with high seismicity, these protocols include fewer load cycles and smaller cumulative damage demands. This opens the door for more competitive solutions in areas with low to medium seismicity. By means of a parametric study on single-degree of freedom systems, new relationships between behavior factor and ductility were established. This makes it possible to apply the N2 method according to Eurocode 8 to light-frame timber structures.

Funding: Swiss National Science Foundation SNSF, National Research Program NRP 66

Partners: EPFL, Earthquake Engineering and Structural Dynamics Laboratory; heig-VD; Pirmin Jung Ingenieure AG; Artho Holz- und Elementbau AG; Lignum – Holzwirtschaft Schweiz; Wenk Erdbebeningenieurwesen und Baudynamik GmbH

Publications:

- Sadeghi Marzaleh A., Steiger R. (2021). Experimental investigation of OSB sheathed timber frame shear walls with strong anchorage subjected to cyclic lateral loading. Engineering Structures 226. Published online: 10 October 2020. https://doi.org/10.1016/j.engstruct.2020.111328

- Sadeghi Marzaleh A., Nerbano S., Sebastiani Croce A., Steiger R. (2018). OSB sheathed light-frame timber shear walls with strong anchorage subjected to vertical load, bending moment, and monotonic lateral load. Engineering Structures 173: 787 – 799. https://doi.org/10.1016/j.engstruct.2018.05.044

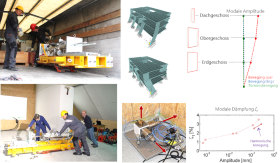

On-site assessment of actual dynamic properties of a multi-story light-frame timber building

A 3-story building with OSB-sheathed light-frame timber walls and timber-concrete composite slabs was subjected to dynamic excitation. The experiments consisted of measurements of the accelerations resulting from forced horizontal vibrations excited by means of a hydraulic actuator shaking a mass of 940 kg. The building was excited in its two main directions to vibrations within a frequency range of 0.2 to 14 Hz. Natural frequencies, modal damping ratios and mode shapes of the building were estimated using accelerations measured in the 4 outer corners of each upper floor. For increasing displacement amplitude (1/8000 to 0.7 mm) the natural frequencies decreased moderately (-15 %) whereas the modal damping ratios increased significantly (+100 %). Modal damping ratios computed using ambient vibration data were smaller than those obtained from forced vibration tests, which suggests that modal damping for the levels of vibration in interest in design might be significantly underestimated if based on ambient vibration testing. However, the mode shapes computed using ambient vibration data turned out to be reliable.

Funding: Federal Office for the Environment FOEN and Cantons (Wald- und Holzforschungsförderung Schweiz WHFF-CH)

Partners: Pirmin Jung Ingenieure AG; Artho Holz- und Elementbau AG; Zindel Brönnimann Ferrario ZBF Architekten AG; Ferrario Bau AG

Publications:

- Steiger R., Feltrin G., Weber F., Nerbano S., Motavalli M. (2017). Experimental modal analysis of a multi-sto-rey light-frame timber building. Bulletin of Earthquake Engineering 15 (8): 3265 – 3291.

https://doi.org/10.1007/s10518-015-9828-9

Friction effects between components of light-frame timber shear walls

Experimental investigations on friction properties between parts of light-frame timber shear walls were carried out, namely between adjacent sheathing panels made of Oriented Strand Board (OSB) and between OSB panels and glued laminated timber (GLT) frame members. The friction stresses were evaluated for different levels of compressive stress and different loading rates in monotonic and cyclic tests. The test results confirmed that the static friction coefficients are larger and have a larger variability than the kinetic friction coefficients. The friction coefficients between the GLT frame members and the OSB panels were in general smaller than the friction coefficients between the sheathing panels themselves. The tests showed that the friction coefficients decrease with increasing cumulative sliding displacement. Analysis of the contact surface before and after the shear test indicated that the sliding reduces the height of the asperities of the contact surfaces. However, after a cumulative displacement of about 100 mm the friction coefficients remain approximately constant.

Funding: Swiss National Science Foundation SNSF, National Research Program NRP 66

Partners: EPFL, Earthquake Engineering and Structural Dynamics Laboratory; Empa Lab Transport at Nanoscale Interfaces

Publications:

- Steiger R., Fink G., Nerbano S., Hack E., Beyer K. (2018). Experimental investigation of friction stresses between adjacent panels made of Oriented Strand Board (OSB) and between OSB panels and glued laminated timber (GLT) frame members. Materials and Structures 51:2.

https://doi.org/10.1617/s11527-017-1124-5

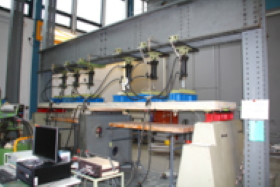

Slabs made of cross-laminated timber panels in composite action with non-reinforced concrete

The project’s aim was to investigate and further develop a slab system consisting of a composite cross-laminated timber / concrete cross-section. The concrete plate has no rebars and the cross-lam panel acts simultaneously as formwork and as tensile reinforcement. Strength, stiffness and failure modes of beam-type elements were investigated in short-term and long-term bending tests. Number, positioning and shape of the shear connectors guaranteeing a rigid connection between cross-lam panel and concrete slab were optimized, taking into account not only stresses when subjected to varying levels of bending moment but also from changes in moisture and from long-term effects as creep and shrinkage.

Funding: Federal Office for the Environment FOEN and Cantons (Wald- und Holzforschungsförderung Schweiz WHFF-CH)

Partners: Pius Schuler AG, Schilliger Holzindustrie AG

-

Share