Advanced Structural Materials and Systems (ASMS)

Our primary mission is to develop and investigate advanced structural materials and systems for use in civil infrastructure. The importance of building modern structures and renovating and conserving existing infrastructure is increasing day by day. Therefore, advanced structural materials are required to improve the load-carrying capacity and serviceability of the existing infrastructure and the design of new structures. Our research aims to make urban living more sustainable, comfortable, resilient, and functional in accordance with the UN Sustainable Development Goals (SDGs) of building sustainable cities and resilient infrastructure. Within our research area, new materials and systems are developed and studied in small and large-scale sizes to demonstrate their application feasibility for civil infrastructure. Currently, our core areas of research are:

- Digital Fabrication and Net-Zero Construction:

- Advanced Carbon Sequestration and Digital Construction for Net-Zero Concrete Structures

- Carbon-Negative Compression Dominant Structures For Decarbonized and Deconstructable Concrete Buildings

- Digital Fabrication of Ribbed Slabs With Post-Tensioned 3D Printed Concrete Formwork

- Development and Characterization of High Performance Materials:

- Eco-UHPC-VP: Eco-friendly Ultra High Performance Concrete, Volumetrically Prestressed with Fe-SMA Fibres

- Short- and long-term creep and stress relaxation of Fe-based shape memory alloys

- Application of Advanced Materials and Structural Systems:

- Self-centering and confining memory steel reinforcements for bridge columns

- FRP Bogie for freight wagons-feasibility study

To achieve our missions, we strongly collaborate with national and international research and industrial partners and experts in the field, including material scientists, manufacturers, acoustic scientists, electrochemistry scientists, engineering scientists, and consulting and construction sectors. Our primary research and collaboration with the industry have already resulted in “technology transfer” and “product development”.

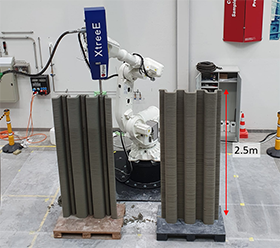

Advanced Carbon Sequestration and Digital Construction for Net-Zero Concrete Structures

This multidisciplinary project involves synergic integration of advanced carbon sequestration and digital fabrication methods for developing next-generation net-zero concrete structures. The project will enable the digital fabrication of CO2-sequestering mixtures prepared using by-products from steel industry. It is expected that the project's outcome may lead to the development of structural elements with at least 50% less embodied CO2 emissions than conventional structural elements. In this way, the project will pave the way to directly benefit from digitization and automation in the building and construction industry to reduce environmental impacts.

Involved staff: Zohaib Hassan, Saim Raza, Moslem Shahverdi

Project Partners:

- ETH Zurich

- Empa Laboratory-506, Advancing Life Cycle Assessment Group

- Empa Laboratory-202, Corrosion & Materials Integrity Group

- Empa Laboratory-304, Mechanical Systems Engineering

- Iowa State University (ISU), USA

- Carbicrete, Canada

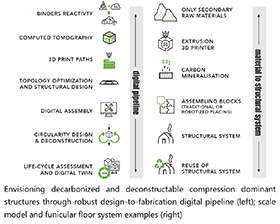

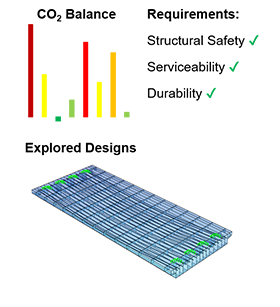

Carbon-Negative Compression Dominant Structures for Decarbonized and Deconstructable Concrete Buildings (CARBCOMN)

CARBCOMN project is a collaborative project funded by the European Innovation Council (Horizon EIC 2023), involving a consortium of 11 research and industry partners across Europe, including Empa. CARBCOMN will create a decarbonised construction system for load-bearing concrete buildings and infrastructure, through an integrated digital pipeline enabling the design, creation and validation of this new system that has circularity features. The project will do this by combining (i) carbon-negative concrete through carbon mineralisation, (ii) zero primary raw materials for making the concrete, (iii) compression dominant structures that are immune for rebar corrosion and become intrinsically more durable, (iv) automated manufacturing of geometrical shapes that drastically reduce material consumption, (v) discretised blocks that allow deconstruction and reuse of entire structures, (vi) shape memory alloys to improve system redundancy, and (vii) life cycle assessment (LCA) integration in form optimised structural designs of these decarbonised and deconstructable concrete load-bearing elements.

Involved staff: Mahsa Sakha, Saim Raza, Matteo Breveglieri, Christoph Czaderski, Moslem Shahverdi

Project Partners:

- ETH Zurich

- Ghent University

- University of Patras

- TU Darmstadt

- Orbix

- Tesis

- Mario Cucinella Architects

- incremental3D

-

re-fer

- Zaha Hadid Architects

- SERI

- European Innovation Council

Digital Fabrication of Ribbed Slabs With Post-Tensioned 3D Printed Concrete Formwork

In this cutting-edge project, digital fabrication technology will be utilized to develop material-efficient floor slab systems. The proposed slab system will comprise stay-in-place permanent 3D printed concrete formwork, and cast-in-place reinforced concrete topping. The state-of-the-art post-tensioning technology by BBR VT International AG will be used to improve the structural performance of the concrete formwork. In addition, topology optimization tools will be implemented to optimize the geometry of the formwork to manufacture slabs with free-form geometries to ensure significant material savings. It is anticipated that the successful completion of this project would lead to a technological paradigm shift in the construction industry, ultimately leading to the adoption of more sustainable and technologically advanced construction methods.

Involved staff: Mahsa, Sakha, Saim Raza, Moslem Shahverdi

Project Partners:

- BBR VT International AG

- ETH Zurich

- Swiss Innovation Agency - Innosuisse, financing

Digital Concrete for Design and Construction of Bridge Infrastructure with Net-Zero Emissions

To help achieve the ambitious goal of Net-Zero CO2 emissions by 2050, this large-scale multidisciplinary project aims at developing a detailed framework for design and construction of bridges with net-zero emissions. The project involves theoretical and numerical studies on alternative bridge designs using different construction materials and techniques. Specifically, the potential/suitability of materials with a low CO2 footprint and construction techniques involving reusable/digitally fabricated concrete formworks will be evaluated for bridge design and construction. The project also aims to develop criteria for assessing and quantifying CO2 neutrality and the performance of bridge structures, and provide support tools for owners and engineers.

Involved staff: Yunus Harmanci, Moslem Shahverdi

Project Partners:

- PSI - Paul Scherrer Institut

- Eawag - Swiss Federal Institute of Aquatic Science and Technology

- WSLS - Swiss Federal Institute for Forest, Snow and Landscape Research

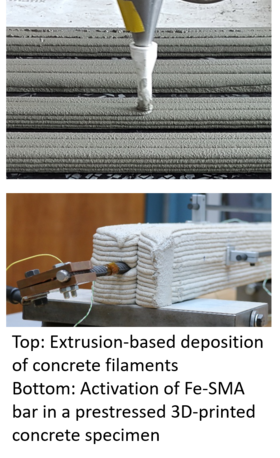

Prestressed Shape Memory Alloy Reinforcement for 3D Concrete Printing

Digital concrete fabrication with additive manufacturing techniques such as extrusion-based 3D concrete printing (3DPC) is expected to revolutionize the construction sector. However, a major obstacle to its wider implementation is the incorporation and efficient utilization of reinforcement within load-bearing 3DPC structures. Amongst the most robust reinforcement methods proposed for overcoming the weak tensile and interfacial behavior of 3DPC is prestressing, typically with post-tensioning steel tendons. This project considers a novel prestressing approach utilizing iron-based shape memory alloy (Fe-SMA) reinforcement, which has already proven very successful in strengthening conventional concrete structures under various loading scenarios. The aim is to investigate the mechanical performance and self-prestressing ability of Fe-SMA-reinforced 3DPC elements to demonstrate the feasibility of this simple but robust method for reinforcing digitally fabricated concrete.

Involved staff: Zafiris Triantafyllidis, Moslem Shahverdi

Project Partners:

- Digital Building Technologies, ITA, ETH Zürich

- Empa Laboratory-308, Concrete & Asphalt Laboratory

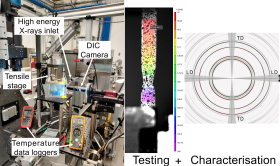

Short- and Long-Term Creep and Stress Relaxation of Fe-based Shape Memory Alloys

Fe-based shape memory alloy (Fe-SMA) application as prestressed reinforcements for structural strengthening and retrofitting increases with time. A typical life span of a reinforced concrete structure is in the range of 50-100 years. Therefore, time-sensitive properties such as creep and stress relaxation of reinforcement play a crucial role in determining the service life of prestressed concrete structures. A short-term recently showed a pronounced amount of creep and relaxation in Fe-SMA at low temperatures. These properties are influenced by the phases present in Fe-SMA and factors leading to transformation. However, transformation kinetics, creep and relaxation mechanism, and long-term behavior remain unknown. Thus, in this project, transformation kinetics will be investigated using an in-situ synchrotron creep and relaxation test. First, various material and application parameters influencing creep and relaxation will be studied. Later, ex-situ experiments will shed light on the long-term behavior of Fe-SMA. Subsequently, long-term data will be used to model the creep and relaxation behavior.

Involved staff: Meet Jaydeepkumar Oza, Christian Leinenbach, Moslem Shahverdi

Project Partners:

- BÖHLER, Austria

- re-fer

- EPFL Laussane

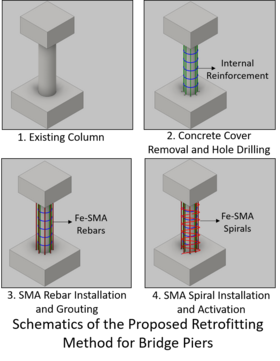

Self-Centering and Confining Memory Steel Reinforcements for Bridge Columns

RC bridge piers may witness a tilt once the earthquake load is over. This tilt can adversely affect the functionality of individual piers and the entire bridge structure by causing misalignment with the elements of the superstructure. Past research has shown that a recentering ability can be added to the bridge piers by prestressing. However, the available prestressing techniques are very cumbersome to implement. To address this challenge, an innovative and easy-to-implement technique that utilizes the unique prestressing characteristics of iron-based shape memory alloy reinforcement will be developed for self-centering and active confinement of bridge piers. The successful implementation of the project will have a tremendous societal impact with respect to keeping bridges and highway networks functional after the extreme loading events and thus ensuring smooth post-disaster response and recovery. Such applications will be studied for the first time, and the developed technique/product will be applied in a pilot project.

Involved staff: Saim Raza, Moslem Shahverdi

Project Partners:

- re-fer AG

- Swiss Innovation Agency - Innosuisse, financing

FRP Bogie for Freight Wagons

Employing composite materials and structures in the railway transit systems, particularly in rail vehicles, brings several significant advantages to this industry: remarkable weight reduction, less noise emission, improved running dynamic, etc. However, the higher cost of materials and manufacturing for FRP structures is the main barrier to such FRP–metal replacements. The focus of this project is to develop a novel design of a hybrid FRP/metal bogie, with optimized per-formance and cost characteristics. In such a hybrid design, FRP components are used only where necessary, serving not only as load-bearing elements but also providing the required flexibility by inte-grating spring functions into the bogie frame.

Involved staff: Ali Saeedi, Samuel Walden, Masoud Motavalli, Moslem Shahverdi

Project Partners:

- BAFU/BAV, Ittigen

- PROSE, Winterthur

- Ensinger, Otelfingen

- Empa 509, Dubendorf

- SBB, Basel

- Wascosa AG, Lucerne

-

Share