Research & Projects

Thin-film materials and coatings are essential to countless state-of-the-art technologies we use every day. Whether a ceramic coating protects a tool from premature wear or a semiconducting thin film enables the touch functionality of a smart phone, many recent technological advancements were enabled by thin-film technology.

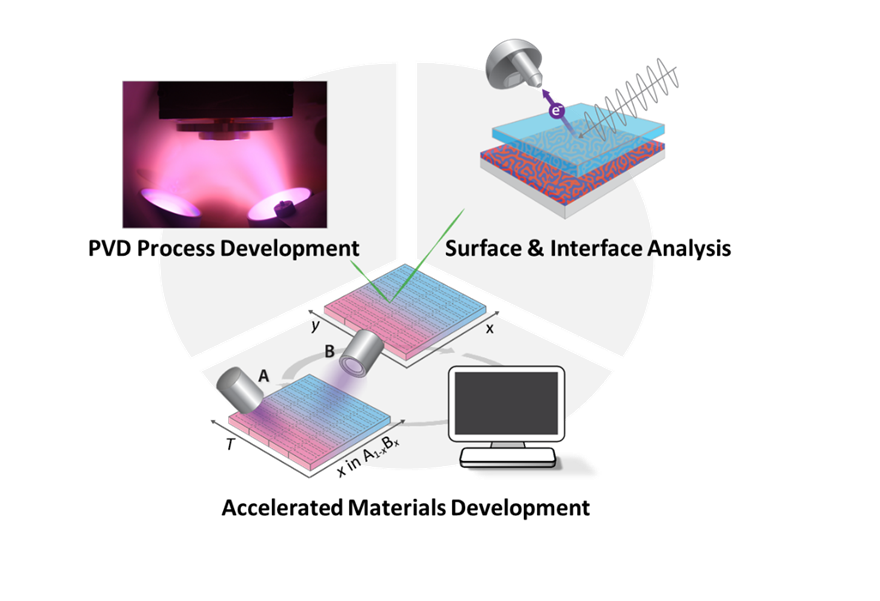

The Coating Technologies group has a long-standing expertise in physical vapor deposition (PVD) of functional thin-films and coatings, with a particular focus on plasma-based processes. Employing a variety of deposition techniques, such as reactive radio frequency magnetron sputtering or high-power impulse magnetron sputtering (HiPIMS) we can tailor the synthesis environment for a large range of materials and applications. Our goal is to understand the synthesis-structure-property relationships in these processes to develop thin-film materials and coatings with improved properties, but also to synthesize entirely new functional materials, such as high-energy metastable phases. We aim to advance thin-film technologies by performing fundamental and applied research in the areas of Process Development, Surface and Interface Analysis, as well as Accelerated Materials Development.

Current projects and recent activities (selected):

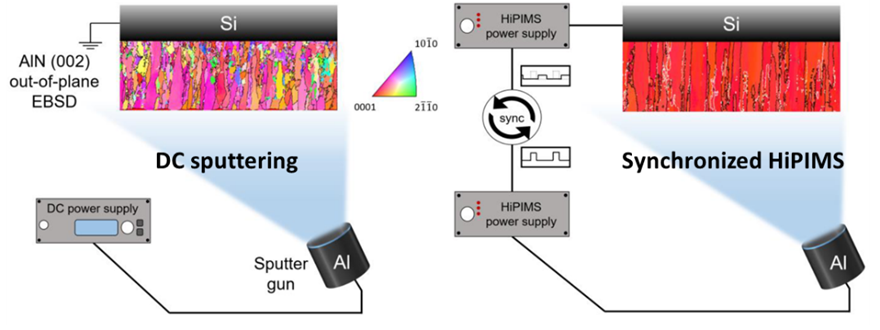

Development of piezo- and ferroelectric thin films using HiPIMS

Piezoelectric and ferroelectric thin films are crucial for many technologies. Their performance is directly linked to their structural properties. Ionized physical vapor deposition techniques offer distinct advantages to control the microstructure of ceramic thin films. We currently explore how novel synthesis approaches, such as of reactive synchronized HiPIMS can be used for the deposition of high-quality piezoelectric AlN and AlScN thin films at moderate temperatures (Funding: SNSF).

Recent publications:

"Low temperature deposition of functional thin films on insulating substrates enabled by selective ion acceleration using synchronized floating potential HiPIMS" - J. Patidar, O. Pshyk, K. Thorwarth, L. Sommerhäuser, S. Siol, Nature Communications 16 (1), 4719, 2025

"Ferroelectric AlScN thin films with enhanced polarization and low leakage enabled by high-power impulse magnetron sputtering" - F. Messi, J. Patidar, N. Rodkey, C.W. Dräyer, M. Trassin, S. Siol, APL Materials 13 (5), 2025

"Deposition of highly crystalline AlScN thin films using synchronized high-power impulse magnetron sputtering: From combinatorial screening to piezoelectric devices" - J. Patidar, K. Thorwarth, T. Schmitz-Kempen, R. Kessels and S. Siol, Physical Review Materials 8 095001, 2024

"Improving the crystallinity and texture of oblique-angle-deposited AlN thin films using reactive synchronized HiPIMS" - J. Patidar, A. Sharma, S. Zhuk, G. Lorenzin, C. Cancellieri, M. F. Sarott, M. Trassin, K. Thorwarth, J. Michler and S. Siol, Surface & Coatings Technology 468, 129719, 2023

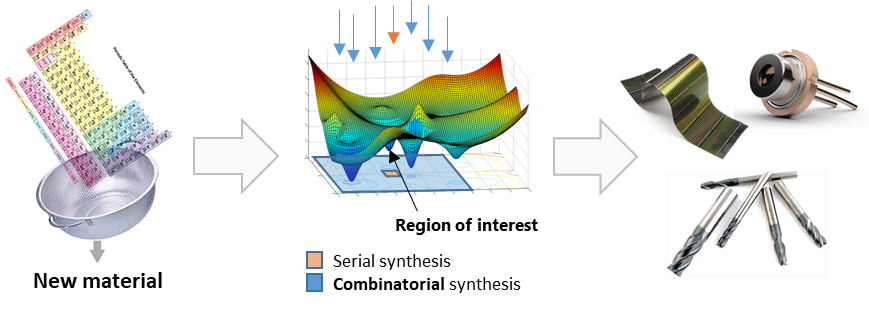

Accelerated development of new functional thin-film materials

New technologies require innovative materials. For instance, nitrides are one group of materials that shows a particularly high innovation potential, with several new phases being reported every year. Using non-equilibrium combinatorial PVD, coupled with automated characterization and data analysis we screen underexplored phase-spaces, and develop promising new materials with tailored functionality. (Funding: Helmut Fischer & Annie Walther Foundation, Innosuisse, Empa, SFA-AM, SNSF)

Recent publications:

"Advancing high-throughput combinatorial aging studies of hybrid perovskite thin films via precise automated characterization methods and machine learning assisted analysis" - A. Wieczorek, A.G. Kuba, J. Sommerhäuser, L.N. Caceres, C.M. Wolff, S. Siol, J. Mat. Chem. A 12 (12), 7025-7035, 2024

"Combinatorial Reactive Sputtering with Auger Parameter Analysis Enables Synthesis of Wurtzite Zn2TaN3" - S. Zhuk, A. Wieczorek, A. Sharma, J. Patidar, K. Thorwarth, J. Michler, S. Siol, Chem. Mater. 2023, 35, 17, 7069–7078

"Synthesis and Characterization of the Ternary Nitride Semiconductor Zn2VN3: Theoretical Prediction, Combinatorial Screening, and Epitaxial Stabilization" – S. Zhuk, A. A. Kistanov, S. C. Boehme, N. Ott, F. La Mattina, M. Stiefel, M. V. Kovalenko and S. Siol, Chem. Mater. 2021, 33, 23, 9306–9316

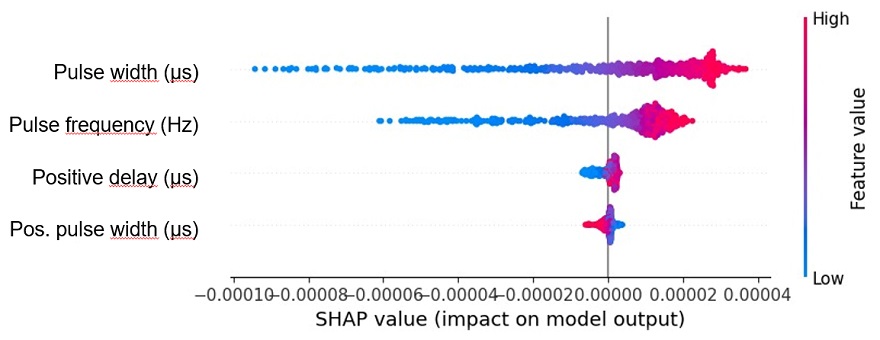

Machine learning for advanced process development

Physical vapor deposition processes, such as HiPIMS, are often characterized by complex, multi-dimensional parameter spaces. Combining real-time plasma diagnostics with smart automation we are developing deposition tools, which can autonomously explore deposition parameter spaces or optimize processes for specified target values using active-learning approaches. This allows us to better understand and optimize even advanced deposition processes for the best possible results. (Funding: SFA-AM, Empa)

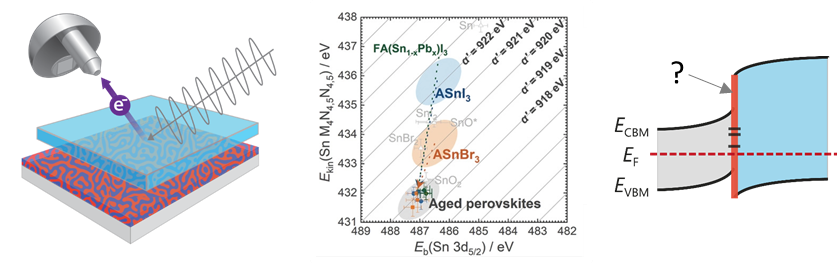

Advanced concepts for surface analysis on functional thin films

X-ray photoelectron spectroscopy necessitates a precise calibration of the energy scale and knowledge of the Fermi level position at the free surface. Consequently, surface contamination and surface band bending often complicate measurements on insulating or semiconducting thin films. We combine clean (UHV or inert gas) sample transfers with robust, but sensitive analysis techniques to provide unique insights into the chemical state and electronic structure of functional thin film surfaces. (Funding: SFA-AM, Empa)

Recent publications:

"Resolving Oxidation States and X–site Composition of Sn Perovskites through Auger Parameter Analysis in XPS" – A. Wieczorek, H. Lai, J. Pious, F. Fu, S. Siol, Adv. Mater. Interfaces 2022, 220182

"Chemical state analysis of reactively sputtered zinc vanadium nitride: The Auger parameter as a tool in materials design" – S. Zhuk, S. Siol, Applied Surface Science 2022, 601, 154172

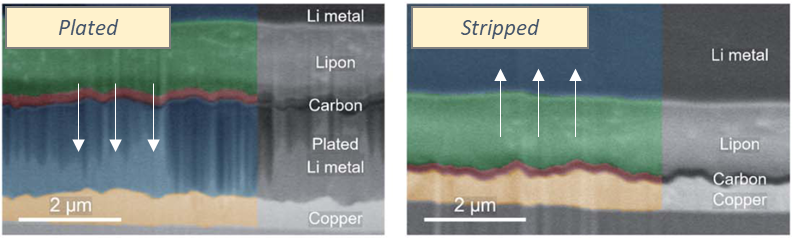

Coatings for next-generation Li-ion batteries

In batteries, high electronic potentials, coupled with reactive environments can result in reduced lifetimes of the embedded components. Together with industrial partners as well as our colleagues from the Laboratory for Materials for Energy Conversion as well as the Laboratory for Thin Films and Photovoltaics we are developing coating solutions to enhance the functionality and durability of electrodes in current and next-generation Li-ion battery technologies. (Funding: Innosuisse, Empa)

Recent publications:

"Influence of amorphous carbon interlayers on nucleation and early growth of lithium metal at the current collector-solid electrolyte interface" – M. H. Futscher, T. Amelal, J. Sastre, A. Müller, J. Patidar, A. Aribia, K. Thorwarth, S. Siol, Y. E. Romanyuk, J. Mater. Chem. A, 2022, 10, 15535-15542

-

Share