Equipment & Services

Overview of services

Our activities focus on wear, friction and lubrication. Complex physical and chemical processes affect the behavior of interfaces during wear. We study the tribological properties of materials and ways to modify them, from macro- and mesoscopic friction down to dissipative processes at the nanoscale. This can be used in the development of new lubricants and investigate the wear and friction behavior of new materials.

Services can range from the measurement of wear rates and friction coefficients to a assessment of the mechanisms of wear and friction. A number of tribometers are available for such studies and can incorporate a variety of specimen geometries and materials. The contacting surfaces can be further investigated using scanning electron microscopy to assess the topography of the worn surfaces, and with ToF-SIMS and XPS to examine the chemistry of the contact zones.

Equipment

The following equipment is available:

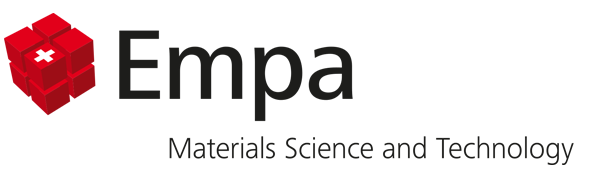

Mini Traction Machine (MTM)

The Mini Traction Machine is mainly used to measure the change in friction with speed for the test fluid. The contacting surfaces are a polished ball (r=19 mm) and disc, both of which are routinely made from 100Cr steel. Both the ball and disc are independently rotated allowing friction measurements at varying slide-roll ratios. Other materials can be used as ball and disc and the steel discs can be coated as required. Alumina, polyethylene, and glass discs are available.

Brugger Testing equipment

This method is designed to determine the ability of a lubricant to protect surfaces during overloading, that is, when the fluid film fails. The test lubricant is smeared over a steel cylinder and a ring. A load is applied to the cylinder and the ring rotates against it. The wear scar on the cylinder is measured and used to calculate the load-bearing capacity of the oil. The method is suitable for determining the lubricating ability of extreme pressure lubricants in the mixed lubrication regime.

High Frequency Reciprocating Rig (HFRR)

In the HFRR, the lower specimen is stationary and the upper specimen reciprocates. The high reciprocating frequencies generally mean that the lubricating regime changes in each stroke from boundary to hydrodynamic. The average friction is measured over each stroke and at the end of the test, the wear scar on the upper specimen can be measured. Additionally, the electrical resistance is measured, which can give some information about processes occurring at the surface such as the formation and removal of oxide layers.

LSTM1 (Low Speed Tribometer)

This equipment consists of a lower specimen holder that reciprocates and an upper, stationary specimen holder to which the load is applied. The lower specimen reciprocates at the chosen frequency and load, stroke length and pause between strokes are also variable parameters. The LSTM1 allows very slow speeds, which is particularly useful for reciprocating friction measurements in the boundary lubrication regime. This equipment is fitted with 3-axis acceleration sensors to measure vibrations and a microphone to record acoustic emissions, which are especially relevant in high friction applications.

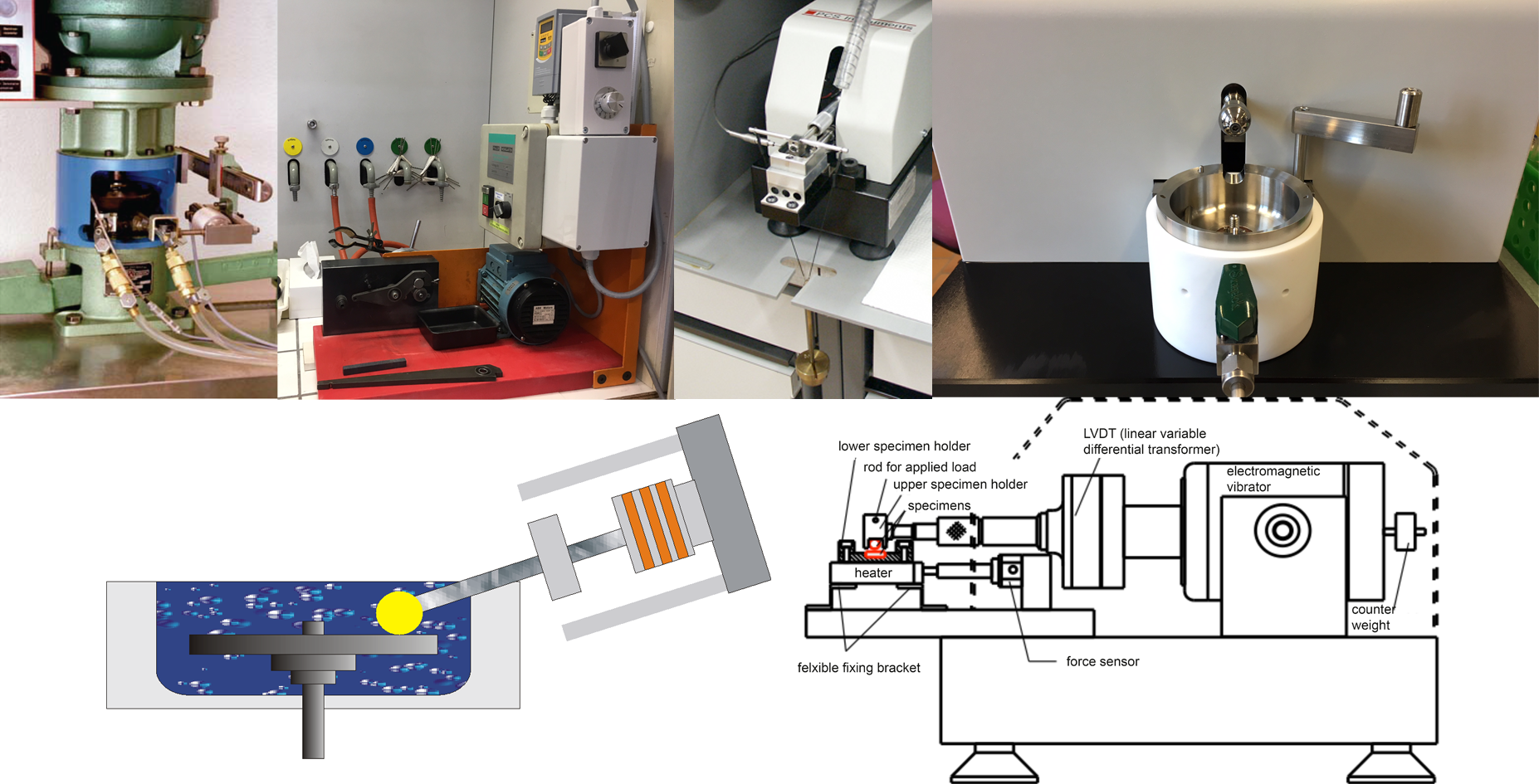

Finger friction measurements

Equipment has also been build to measure the friction of the finger against materials such as glass or plastics. The applied load and friction force are measured continuously during sliding. Speed is determined using a gopro camera. Vibrations can also be measured if required.

-

Share