Polyimide aerogels

Polyimides are high-performance engineering polymers with inherent attributes of good mechanical property, low permittivity and excellent chemical stability when exposed to high temperature or harsh chemical environments. Polyimide aerogels are porous materials with the intrinsic chemical composition and properties of polyimide materials, generally prepared by the sol-gel process, followed by supercritical CO2 drying. However, a high degree of volume shrinkage is common for polyimide aerogels after exposure to temperatures above 200 °C), resulting in their underutilization for high temperature applications.

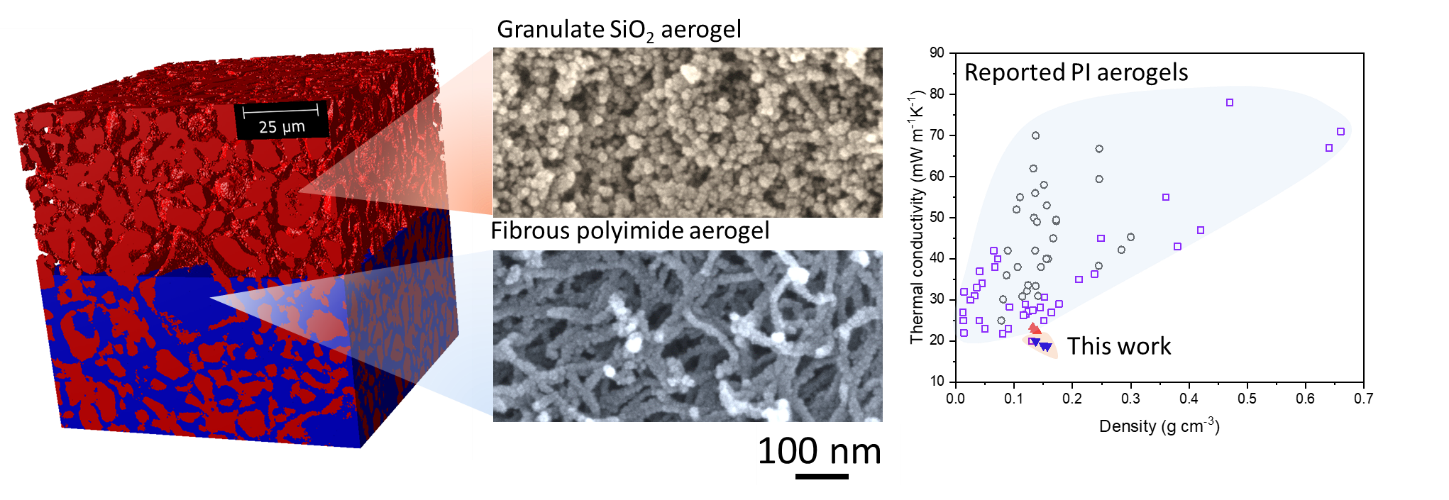

To solve this problem, in our group we developed an aerogel-in-aerogel composites that comprise of silica aerogel grains with a nanoparticulate microstructure embedded in a nanofibrous polyimide aerogel matrix. The composites display a unique, heterogeneous structure with a high surface area, >600 m2 g-1, a low thermal conductivity down to 17.5 mW m-1 K-1, and most importantly, a much-reduced volume shrinkage at high temperature (up to 400 °C).

In addition to the work on the silica-polyimide composites, we pursue novel microstructures in pure polyimide aerogel. Instead of regular 3D interconnected nanofiber networks, we have created a new kind of pore structures by stacking 1-10 µm microspheres that themselves consist of nanofiber strands. These hierarchical structures emerge by controlling the phase separation of polyimide aerogels induced by the chemical imidization and the resulting gels can be dried via oven drying as well as supercritical drying. The final aerogels display excellent dimensional stability in high-temperature conditions over long periods of time.