Medical textiles and sensors

Smart protection for delicate skin

Skin injuries caused by prolonged pressure often occur in people who are unable to change their position independently – such as sick newborns in hospitals or elderly people. Thanks to successful partnerships with industry and research, Empa scientists are now launching two smart solutions for pressure sores.

If too much pressure is applied to our skin over a long period of time, it becomes damaged. Populations at high risk of such pressure injuries include people in wheelchairs, newborns in intensive care units and the elderly. The consequences are wounds, infections and pain.

Treatment is complex and expensive: Healthcare costs of around 300 million Swiss francs are incurred every year. "In addition, existing illnesses can be exacerbated by such pressure injuries," says Empa researcher Simon Annaheim from the Biomimetic Membranes and Textiles laboratory in St. Gallen. According to Annaheim, it would be more sustainable to prevent tissue damage from occurring in the first place. Two current research projects involving Empa researchers are now advancing solutions: A pressure-equalizing mattress for newborns in intensive care units and a textile sensor system for paraplegics and bedridden people are being developed.

Optimally nestled at the start of life

The demands of our skin are completely different depending on age: In adults, the friction of the skin on the lying surface, physical shear forces in the tissue and the lack of breathability of textiles are the main risk factors. In contrast, the skin of newborns receiving intensive care is extremely sensitive per se, and any loss of fluid and heat through the skin can become a problem. "While these particularly vulnerable babies are being nursed back to health, the lying situation should not cause any additional complications," says Annaheim. He thinks conventional mattresses are not appropriate for newborns with very different weights and various illnesses. Annaheim's team is therefore working with researchers from ETH Zurich, the Zurich University of Applied Sciences (ZHAW) and the University Children's Hospital Zurich to find an optimal lying surface for babies' delicate skin. This mattress should be able to adapt individually to the body in order to help children with a difficult start in life.

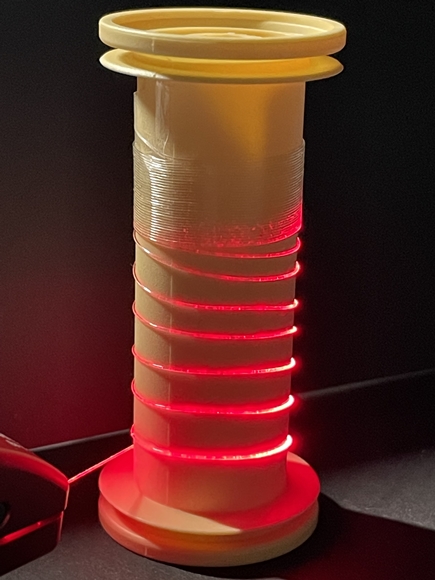

In order to do this, the researchers first determined the pressure conditions in the various regions of the newborn's body. "Our pressure sensors showed that the head, shoulders and lower spine are the areas with the greatest risk of pressure sores," says Annaheim. These findings were incorporated into the development of a special kind of air-filled mattress: With the help of pressure sensors and a microprocessor, its three chambers can be filled precisely via an electronic pump so that the pressure in the respective areas is minimized. An infrared laser process developed at Empa made it possible to produce the mattress from a flexible, multi-layered polymer membrane that is gentle on the skin and has no irritating seams.

After a multi-stage development process in the laboratory, the first small patients were allowed to lie on the prototype mattress. The effect was immediately noticeable when the researchers filled the mattress with air to varying degrees depending on the individual needs of the babies: Compared to a conventional foam mattress, the prototype reduced the pressure on the vulnerable parts of the body by up to 40 percent.

Following this successful pilot study, the prototype is now being optimized in the Empa labs. Simon Annaheim and doctoral student Tino Jucker will soon be starting a larger-scale study with the new mattress with the Department of Intensive Care Medicine & Neonatology at University Children's Hospital Zurich.

Intelligent sensors prevent injuries

In another project, Empa researchers are working on preventing so-called pressure ulcer tissue damage in adults. This involves converting the risk factors of pressure and circulatory disorders into helpful warning signals.

If you lie in the same position for a long time, pressure and circulatory problems lead to an undersupply of oxygen to the tissue. While the lack of oxygen triggers a reflex to move in healthy people, this neurological feedback loop can be disrupted in people with paraplegia or coma patients, for example. Here, smart sensors can help to provide early warning of the risk of tissue damage.

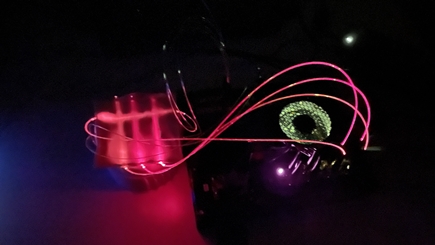

In the ProTex project, a team of researchers from Empa, the University of Bern, the OST University of Applied Sciences and Bischoff Textil AG in St. Gallen has developed a sensor system made of smart textiles with associated data analysis in real time. "The skin-compatible textile sensors contain two different functional polymer fibers," says Luciano Boesel from Empa's Biomimetic Membranes and Textiles laboratory in St. Gallen. In addition to pressure-sensitive fibers, the researchers integrated light-conducting polymer fibers (POFs), which are used to measure oxygen. "As soon as the oxygen content in the skin drops, the highly sensitive sensor system signals an increasing risk of tissue damage," explains Boesel. The data is then transmitted directly to the patient or to the nursing staff. This means, for instance, that a lying person can be repositioned in good time before the tissue is damaged.

Patented technology

The technology behind this also includes a novel microfluidic wet spinning process developed at Empa for the production of POFs. It allows precise control of the polymer components in the micrometer range and smoother, more environmentally friendly processing of the fibers. The microfluidic process is one of three patents that have emerged from the ProTex project to date.

Another product is a breathable textile sensor that is worn directly on the skin. The spin-off Sensawear in Bern, which emerged from the project in 2023, is currently pushing ahead with the market launch. Empa researcher Boesel is also convinced: "The findings and technologies from ProTex will enable further applications in the field of wearable sensor technology and smart clothing in the future."

ProTex: A successful inter-institutional team

With the BRIDGE funding scheme, the Swiss National Science Foundation (SNSF) and the Swiss Innovation Agency Innosuisse support projects that demonstrate scientific excellence, a clear implementation strategy and economic and social potential. The team led by Luciano Boesel (Empa), Guido Piai (OST) and Ursula Wolf (University of Bern) was convincing, and ProTex was funded as part of BRIDGE Discovery. "Together, we have the necessary expertise in the fields of materials, optics, electronics, medicine and technology," says Empa researcher Boesel, describing the successful collaboration in the interdisciplinary team.

Donations that make a difference

This research project was launched thanks to a generous donation from one foundation. The Empa Zukunftsfonds, Empa's research promotion program, is constantly seeking private third-party funding to finance such innovative projects and enable young talents to start their scientific career. Further information: /web/zukunftsfonds

Dr. Simon Annaheim (Neugeborenen-Projekt Prepicare)

Biomimetic Membranes and Textiles

Phone +41 58 765 7768

Dr. Luciano Bösel (ProTex)

Biomimetic Membranes and Textiles

Phone +41 58 765 7393

Empa Quarterly#82 Mining the Atmosphere

To limit climate change, we need to compensate not only for future emissions, but also for historical ones. One solution would be the "atmospheric vacuum cleaner": we remove the excess CO2 from the atmosphere. But what do we do with it? Instead of extracting the carbon for polymers, medicines, fibers, fuels and the like from crude oil, we use atmospheric CO2. This is the simple – yet extremely challenging in technical terms – idea behind Empa's new research initiative, Mining the Atmosphere.

Read the EmpaQuarterly online or download the pdf-version.

Empa Quarterly#83 Perovskites: Versatile cristals

Over 180 years ago, a curious crystal was discovered in the Ural Mountains. Today, it has given rise to an entire class of materials that is of great interest to researchers: perovskites. What all perovskites have in common is their crystal structure, which gives them unusual properties. By changing the exact composition of the perovskite, scientists can control these properties. Empa researchers are using this promising material to develop solar cells, detectors and quantum dots.

Read the EmpaQuarterly online or download the pdf-version.

-

Share

|

The green delight The Christmas tree in this picture doesn't need any candles. It glows bright green all by itself – thanks to bioluminescence. Empa researcher Francis Schwarze has developed a process for producing bioluminescent wood using fungi. |

|

CO2-binding society Empa Director Tanja Zimmermann and Eawag Director Martin Ackermann want to provide answers to the climate crisis with new initiatives and ambitious goals. |