Materials research

Voltage from the parquet

Researchers at Empa and ETH Zurich have made wood flexible and turned it into a micro-generator. When it is loaded, electrical voltage is generated. In this way, the wood can serve as a bio-sensor – or generate usable energy.

Ingo Burgert and his team have proven it time and again: Wood is so much more than "just" a building material. Their research aims at extending the existing characteristics of wood in such a way that it is suitable for completely new ranges of application. For instance, they have already developed high-strength, water-repellent and magnetizable wood. In a recent study, his team, collaborating with the research group led by Francis Schwarze, has shown how electricity can be generated by some kind of "wood sponge" using a simple chemical process. This is where the so-called piezoelectric effect comes into play.

Voltage due to deformation

Piezoelectricity means that an electric voltage is created by the elastic deformation of solids. This phenomenon is mainly exploited by metrology, which uses sensors that generate a charge signal, say, when a mechanical load is applied. However, such sensors often use materials that are unsuitable for use in biomedical applications, such as lead zirconate titanate (PZT), which cannot be used on human skin due to the lead it contains. It also makes the ecological disposal of PZT and Co rather tricky. Being able to use the natural piezoelectric effect of wood thus offers a number of advantages. If thought further, the effect could also be used for sustainable energy production. But first of all, wood must be given the appropriate properties. Without special treatment, wood is not flexible enough; when subjected to mechanical stress; therefore, only a very low electrical voltage is generated in the deformation process.

From block to sponge

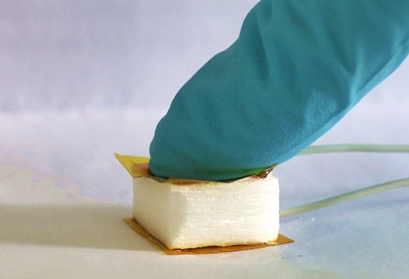

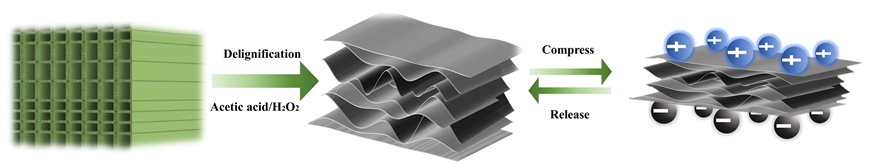

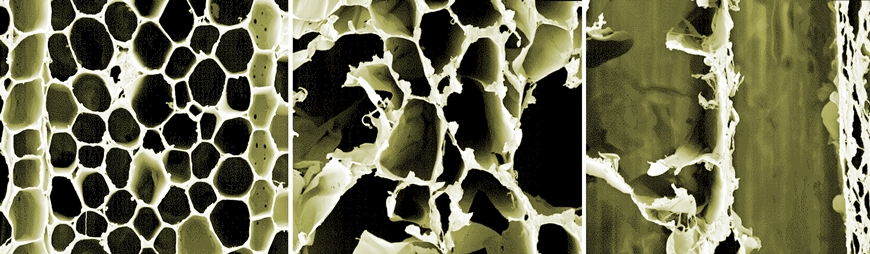

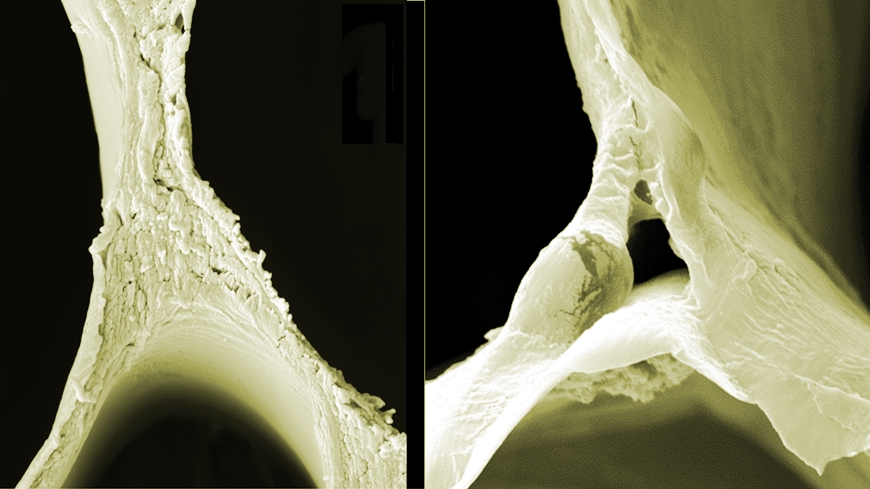

Jianguo Sun, a PhD student in Burgert's team, used a chemical process that is the basis for various "refinements" of wood the team has undertaken in recent years: delignification. Wood cell walls consist of three basic materials: lignin, hemicelluloses and cellulose. "Lignin is what a tree needs primarily in order to grow to great heights. This would not be possible without lignin as a stabilizing substance that connects the cells and prevents the rigid cellulose fibrils from buckling," explains Burgert. In order to transform wood into a material that can easily be deformed, lignin must at least partially be "extracted". This is achieved by placing wood in a mixture of hydrogen peroxide and acetic acid. The lignin is dissolved in this acid bath, leaving a framework of cellulose layers. "We take advantage of the hierarchical structure of wood without first dissolving it, as is the case in paper production, for example, and then having to reconnect the fibers", says Burgert. The resulting white wood sponge consists of superimposed thin layers of cellulose that can easily be squeezed together and then expand back into their original form – wood has become elastic.

Electricity from wooden floors

Burgert's team subjected the test cube with a side length of about 1.5cm to about 600 load cycles. The material showed an amazing stability. At each compression, the researchers measured a voltage of around 0.63V – enough for an application as a sensor. In further experiments, the team tried to scale up their wooden nanogenerators. For example, they were able to show that 30 such wooden blocks, when loaded in parallel with the body weight of an adult, can light up a simple LCD display. It would therefore be conceivable to develop a wooden floor that is capable of converting the energy of people walking on it into electricity. The researchers also tested the suitability as a pressure sensor on human skin and showed that it could be used in biomedical applications.

However, there is still a long way to go before the "piezo" wood can be used as a sensor or even as an electricity-generating wooden floor. But the advantages of such a simple yet renewable and biodegradable piezoelectric system are obvious – and are now being investigated by Burgert and his colleagues in follow-up projects.

Prof. Dr. Ingo Burgert

Cellulose & Wood Materials

Phone +41 58 765 45 08

Prof. Dr. Francis Schwarze

Cellulose & Wood Materials

Phone +41 58 765 7247

Francis.Schwarze@empa.ch

J Sun, H Guo, GN Schädli, K Tu, S Schär, FWMR Schwarze, G Panzarasa, J Ribera, I Burgert; (2021);

J Sun, H Guo, J Ribera, C Wu, K Tu, M Binelli, G Panzarasa, FWMR Schwarze, ZL Wang, I Burgert; Sustainable and Biodegradable Wood Sponge Piezoelectric Nanogenerator for Sensing and Energy Harvesting Applications; ACS Nano (2020); https://doi.org/10.1021/acsnano.0c05493

Pavement Printing

Knitting roads

Empa scientists are investigating how roads could be reinforced with simple means and recycled easily after use. Their tools are a robot and a few meters of string. (Image: Gramazio Kohler Research / ETH Zürich / Martin Rusenov).

>>>>

Biotechnology

The black gold of fungi

Empa researchers have succeeded in extracting the pigment melanin in large quantities from a fungus. The gigantic Armillaria fungus in the service of science is one of the largest and oldest living organisms in the world. Potential applications for the "black gold" range from wood preservatives to the construction of water filters and historic musical instruments. (Image: Empa).

>>>>

Developing countries

Tailor-made power grids

In her PhD thesis, Empa researcher Crisitina Dominguez is developing a computer model, which can be used to plan electricity grids in developing countries. To collect data, she travelled to Kenya to get an idea of how people live without electricity and what developments access to the power grid can trigger. (Image: Empa / ETH).

>>>>