NanoHouse - Life cycle of nanoparticle-based façade coatings

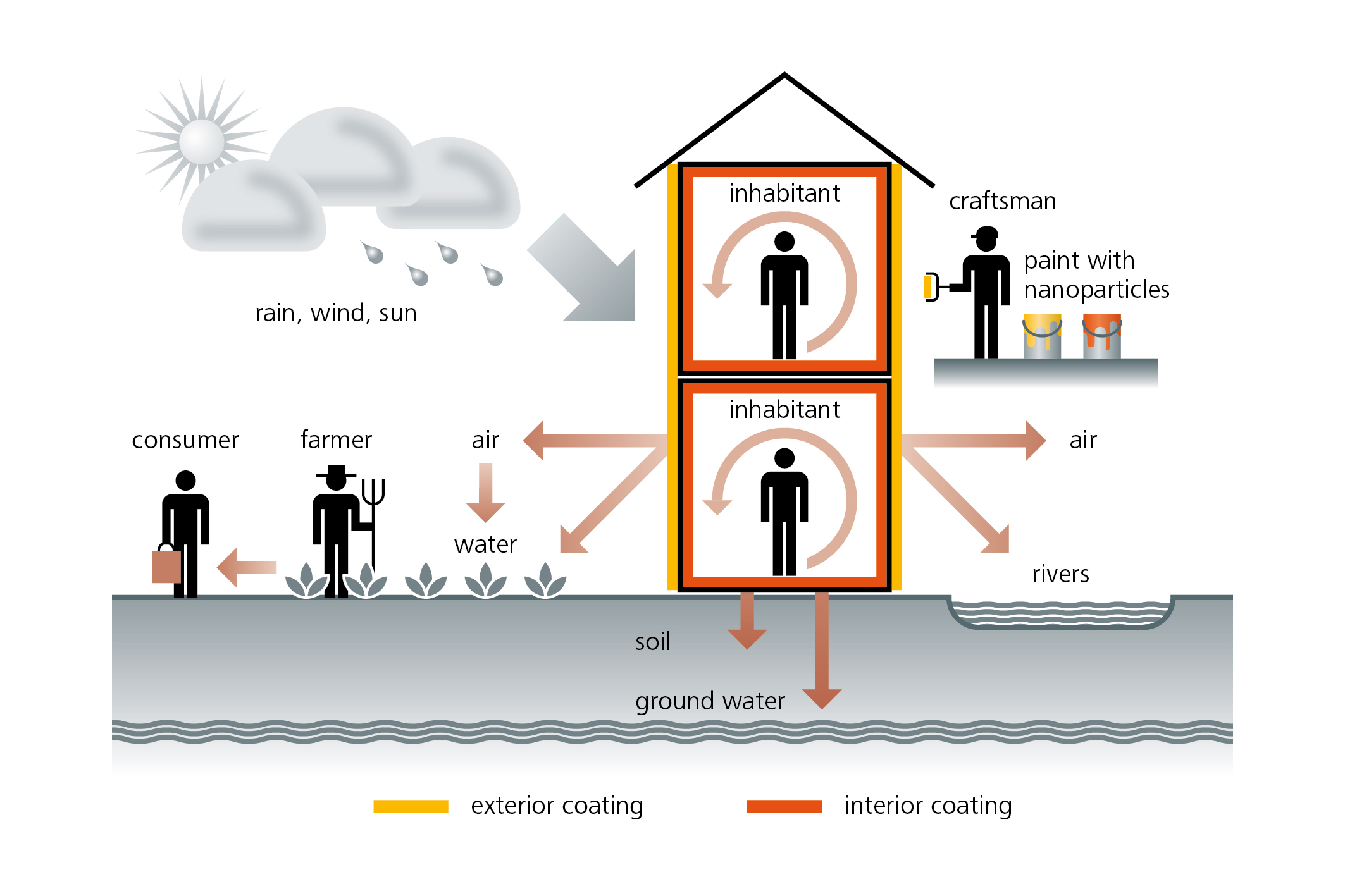

The integration of engineered nanoparticles (ENPs) in façade coatings may lead to improved or new functionalities during their life cycle and may bring several sustainable advantages; they may replace hazardous substances, prolong the life time of façade coatings and they can be advantageously used for air purification, thermal insulation, self-cleaning, and other. Nevertheless, the use of nanomaterials in this economic area can grow dynamically only if the safety of humans and the environment is satisfactorily resolved.

NanoHouse aimed promoting a responsible and sustainable inclusion of nanomaterials in the paint industry through a Life Cycle Thinking (LCT) approach and understand whether the potential benefits of three façade coatings containing different ENPs (nano-TiO2, nano-SiO2, and nano-Ag) can outbalance their potential risks for human health and the environment during the whole product life cycle.

Together with partners from industry and research experiments on the unintended release of ENP from facade coatings were done. An innovative aspect was to investigate the hazard and behaviour of “aged” ENP and compared them to pristine ENP. Additionally a survey on benefits and risks and a respective LCA was performed.

Conclusions and Recommendations

The results from here investigated ENPs and paints cannot be generalized for other types of ENPs and nano-paints and long term effects should be further investigated. Nevertheless, the most important hot spots for releaseidentified were: Airborne inhalation during ENPs’ production, renovation or recycling of construction materials, « nanowaste » from the production of ENP, integration of ENPs in paints and their use, and the disposal of industrial waste and residues from incineration on landfills

To maximise the benefits and minimize the risks of ENP in paints, general recommendations for manufactures were provided:

- Explore the potential for functional benefits and for improved environmental performance during early stages of innovation accurately

- Test functional improvements

- Use safe design (ENP type and bonding in paint)

- Use ENPs in their gel or fluid formulation

- Avoid airborne particles and dust formation

- Assure proper disposal of residues, that established recycling systems will not be disturbed and pre-treatment of industrial waste water

For more information about the methodology and results from LCT, fate and behaviour of ENPs in the environment and their toxicity, see the following dissemination reports.

Publications

I Hincapie, T Künniger, R Hischier, D Cervellati, B Nowack, C Som (2015) Nanoparticles in facade coatings: a survey of industrial experts on functional and environmental benefits and challenges J Nanopart Res 17: 287. 1-12. (pdf)

Al-Kattan, A.; Wichser, A.; Vonbank, R.; Brunner, S.; Ulrich, A.; Zuin, S.; Arroyo, Y.; Golanski, L.; Nowack, B., Characterization of materials released into water from paint containing nano-SiO2. Chemosphere 2015, 119, 1314–1321. (pdf)

Hischier, R.; Nowack, B.; Gottschalk, F.; Hincapie, I.; Steinfeldt, M.; Som, C., Life cycle assessment of facade coating systems containing manufactured nanomaterials. Journal of Nanoparticle Research 2015, 17. (pdf)

Al-Kattan, A.; Wichser, A.; Zuin, S.; Arroyo, Y.; Golanski, L.; Ulrich, A.; Nowack, B., Behavior of TiO2 released from nano-TiO2-containing paint and comparison to pristine nano-TiO2. Environmental Science & Technology 2014, 48, 6710−6718. (pdf)

Al-Kattan, A.; Wichser, A.; Vonbank, R.; Brunner, S.; Ulrich, A.; Zuin, S.; Nowack, B. (2013) Release of TiO2 from paints containing pigment-TiO2 or nano-TiO2 by weathering. Environmental Science: Processes & Impacts 15: 2186-2193. [pdf]

Kaiser J.-P., Zuin S and Wick P. Is nanotechnology revolutionizing the paint and lacquer industry? A critical opinion. Science of the Total Environment 2013, 442:282-289.

Som, C.; Nowack, B.; Krug, H.F.; Wick, P. (2013) Towards the development of decision supporting tools that can be used for safe production and use of nanomaterials. Accounts in Chemical Research 46: 863–872. [pdf]

Hischier, R.; Walser, T. (2012) Life cycle assessment of engineered nanomaterials: State of the art and strategies to overcome existing gaps. Science of the Total Environment. 425 (2012) 271–282. [DOI]

Smulders, S., Kaiser, JP., Zuin, S., Van Landuyt, KL, Golanski, L., Vanoirbeek, J., Wick, P., Hoet, PHM. (2012). Contamination of nanoparticles by endotoxin: evaluation of different test methods. Part Fibre Toxicol, 9:41.

Ulrich, A.; Losert, S.; Bendixen, N.; Al-Kattan, A.; Hagendorfer, H.; Nowack, B.; Adlhart, C.; Ebert, J.; Lattuada, M.; Hungerbühler, K. (2012) Critical aspects of sample handling for direct nanoparticle analysis and analytical challenges using asymmetric field flow fractionation in a multi-detector approach. J. Anal. At. Spectrom. 27: 1120-1130. [pdf]

Som, C.; Wick, P.; Krug, H.; Nowack, B. (2011) Environmental and health effects of nanomaterials in nanotextiles and façade coatings. Environ. Int. 37: 1131–1142. [pdf]

Publications from other partners of NanoHouse can be found here.

Claudia Som

Empa

Technology & Society Laboratory

Lerchenfeldstrasse 5

CH-9014 St. Gallen

Tel.: +41 58 765 76 92

claudia.som@empa.ch

-

Share