Machine Learning for Multiscale Thermal Simulation of Additive Manufacturing

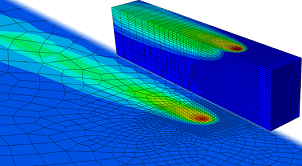

Understanding the evolution of temperature profiles during the metal additive manufacturing process is the first step towards investigating the development of residual stresses, microstructure, and properties of the manufactured components. Thus, reliable thermal simulations are essential in studying the MAM process, where efficient models with minimal uncertainties would act as the input to sequentially coupled mechanical and microstructural analyses.

The fast kinetics and highly localized nature of the phenomena involving melting and solidification of metal powder demand fine time and space discretization for solving the heat transfer equations around the high-intensity localized heat source (e.g. laser). This requirement significantly increases the computational costs and makes part-scale calculations prohibitively expensive. Existing simplified simulation approaches apply gross approximations to overcome the numerical cost barrier and introduce high levels of uncertainty that ignores important process details. This project combines multiscale modelling and machine learning to enable part-scale high fidelity simulations and fast thermal analysis without compromising accuracy. The efficiency and reliability of the proposed idea have been demonstrated for 2D thermal simulations [1,2]. This project is running in collaboration with Risk, Safety and Uncertainty Quantification and Seminar for Applied Mathematics from ETHZ.

Microstructure and Mechanical Property Prediction for Laser Powder Bed Fusion Process

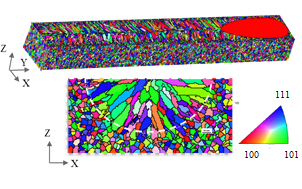

It is widely acknowledged that the microstructure of additively manufactured builds is considerably different to those observed in the cast or wrought alloys. AM microstructure is characterized by fine-elongated grains oriented in the build direction. Accordingly, anisotropic high strengths at room temperature and low creep performance at elevated temperatures were often observed for AM alloys. Parameters such as grain size, shape, crystallographic orientation and consequently, the mechanical properties were found to be very sensitive to the AM process parameters and therefore tuning the process conditions allows for the fabrication of builds with desired properties. Notably, the adoption of process conditions for different sites of a part enables the fabrication of functionally graded microstructures.

Full exploitation of the AM process potentials for designing the microstructure requires a deep understanding of microstructure development during the deposition process and its relationship with the resulted mechanical properties (i.e. process-microstructure-property correlation). The running PhD project, in collaboration with the Computational Mechanics Group at ETH aims to develop a cellular automata-crystal plasticity finite element simulation framework for microstructure and mechanical properties simulation for AM process. Moderating the computational cost of such a detailed analysis through machine learning is planned.

Machine Learning for Multiscale Simulations of Residual Stresses and Distortion in Laser Powder Bed Additive Manufacturing

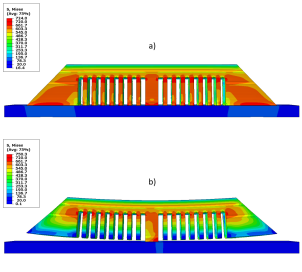

While additive manufacturing enables the production of functionally graded materials and complex topologies, its employment to fabricate ready-to-use components is often inhibited by the induced distortions and residual stresses. Steep temperature gradients and high cooling rates are involved during the process upon localised heat input. The resulted thermal strains induce inhomogeneously distributed plastic deformation, and thus residual stresses that can cause distortion and cracking of the built, affecting the geometrical accuracy and mechanical integrity of the products. To realise a 'first-time-right' high-quality production, a deeper understanding of the residual stress development process through high-fidelity numerical simulations, and therefore, development of residual stress and distortion mitigation strategies are required. The high computational cost of such detailed simulations is a barrier against their adoption for the real-size components. Typically, gross simplifications at the expense of accuracy and reliability have been taken by the previous research for part-scale analyses.

After re-examining the common assumptions in the high-fidelity thermomechanical simulation (e.g. the employed constitutive model types), this PhD project exploits the power of multiscale modelling and machine learning algorithms to realise reliable component-scale simulations for accurate prediction of distortion and residual stresses in AM components.

Neural Network Based Finite Element Method

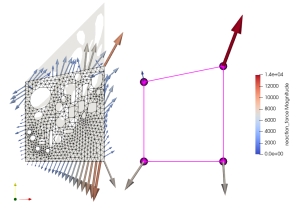

Additive manufacturing technologies offer enormous design freedom and enable the fabrication of highly complex geometries that would otherwise be too difficult or costly to be manufactured by traditional methods. In order to take full advantage of the design freedom offered by AM, reliable and economical numerical models are necessary. In particular, the accurate resolution of heterogeneous structures and multi-scale structures is essential to obtain enhanced control over AM fabricated parts requiring temporary support during the build. In this context, a multi-resolution framework is developed that allows the modelling of part scale behaviour on the one side as well as an adequate resolution of fine-scale features on the other side. The element-based scale bridging strategy is exploited to derive efficiently functionality graded lattice structures utilizing Topology Optimization. It is envisaged to use the framework in order to derive part-specific optimized support structures that play a key role in additive manufacturing.

Within the ongoing PhD project, in collaboration with ZHAW and ETHZ, the development of a Deep Learning based finite element method is aimed for. The envisaged framework exploits the Geometric Multiscale Finite Element Method as a scale bridging strategy that allows a finite element discretization via user-defined multi-node super elements. The super-element itself is fully controlled by a pre-trained Machine Learning model that provides necessary quantities for the Finite Element solver on the one side and additional information about the fine-scale behaviour on the other side.