SUBITEX – Sustainable Biomedicine Textiles

Sustainable biomedical textiles for the future

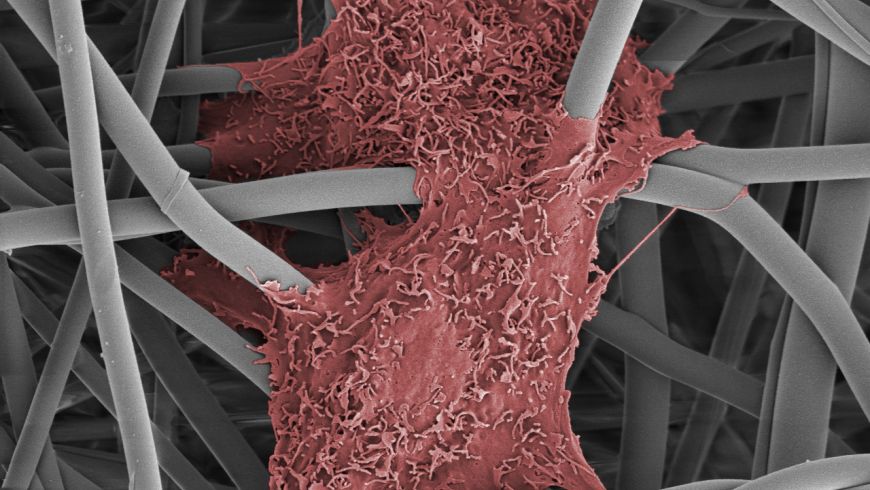

Textiles are especially suitable for use on and in the human body. The body itself consists of many fibers too, including muscle, tendon and nerve fibers. Textiles can also be used to make copies of entire organs or parts of them. One current example of this is a major project involving Empa, called "Zurich Heart": under the aegis of the Zurich University Medicine initiative, in collaboration with the University Hospital, the University and ETH (Swiss Federal Institute of Technology) Zurich, Empa researchers are developing an artificial heart pump. This will include a fleece textile with a layer of heart muscle cells, which will not be detected by the blood as a foreign body.

"We need to say goodbye to the idea that the development of textiles revolves around cotton T-shirts", says René Rossi, Subitex project manager and head of Empa's Biomimetic Membranes and Textiles lab. Instead, according to Rossi, their research is focused on a very wide range of ceramic, metal, wood, and synthetic fibers. "A textile is not just a cloth either, but rather a two-dimensional entity derived from a one-dimensional material: a fiber," he adds. The entities derived from this are flexible, malleable, stretchable, and light knitted, woven, or crocheted fabrics. Rossi continues: "Theoretically, there are no limits to textile materials or their properties."

Many Swiss textile companies have also recognized this, successfully transforming themselves into specialist manufacturers of highly technical and high-quality products. They have networked more and more intensively with researchers and have skilfully occupied economic niches. Empa offers its services as a research partner precisely because it draws a line from basic research, as in the case of the "Zurich Heart" project, all the way to products that are close to the market. For example, it has developed optical fibers that are used in hospitals to measure the vital functions of premature babies, or as biosensors with pH-sensitive fibers to monitor wounds. Other examples of applications include textile pressure sensors that can be installed in wheelchairs, for instance, in order to show incorrect pressure loads; textile plasters that release medication in a targeted way; and a wettable chest strap that can be reliably used for long-term monitoring of electrocardiograms for cardiovascular patients.

A research initiative with 15 industrial partners

In order to promote further innovations and make even better use of the vast all-round potential of textiles, Empa and the Swiss industrial association, Swiss Textiles, established the "SUBITEX" research initiative two years ago. The development and use of innovative materials, fibers, fabrics and processes should assure Swiss textile companies a long-term competitive advantage in the global market. As part of this initiative, ten projects co-financed by the Commission for Technology and Innovation (KTI) have already been launched. Fifteen textile companies have now joined the initiative, including Flawa AG, Cilander, E. Schellenberg Textildruck AG, Mammut Sports Group, Schoeller Textil AG, Serge Ferrari Tersuisse AG, and TISCA Tischhauser & Co. AG.

So that it can pass on even more textile expertise to Subitex partners, Empa has invested part of the financial contributions from Subitex in the "Self-care materials" research program of the Competence Center for Materials Science and Technology (CCMX) of the ETH domain. This program investigates the substance emission and absorption properties of fiber structures. The CCMX program is a mix of basic and industrial research and is extremely lucrative, because the Swiss National Fund (SNF) contributes the same amount to the program as that contributed by the industry.

For this purpose, Empa's electrospinning and microfluidics systems develop fiber systems from smart polymers. These systems respond to external influences such as temperature, pH value, humidity, or pressure. Today's systems use small, passive capsules that can only release substances by decomposing. What makes self-care materials special is that their innovative fiber systems release substances in a targeted way over a specific period of time when they are "activated". Very small fibers made from smart polymers can be used not only in biomedical textiles and fabrics, but also in packaging films for the food industry.

The SUBITEX research initiative is scheduled to last five years and will continue to run until 2020. For further information, see: http://subitex.empa.ch

Swiss Textiles at Techtextil 2017

The international leading fair for technical textiles will take place from 9 to 12 May in Frankfurt. Swiss Textiles will organize a joint booth for Swiss textile companies. Empa will also be represented with a stand.

-

Share