A strategic partnership – thanks to NEST

Together to the recyclable house

Stahlton Bauteile AG and zirkulit AG have formed a strategic partnership – initiated by their collaboration in the latest NEST unit, STEP2. The goal is to jointly realize recyclable concrete buildings.

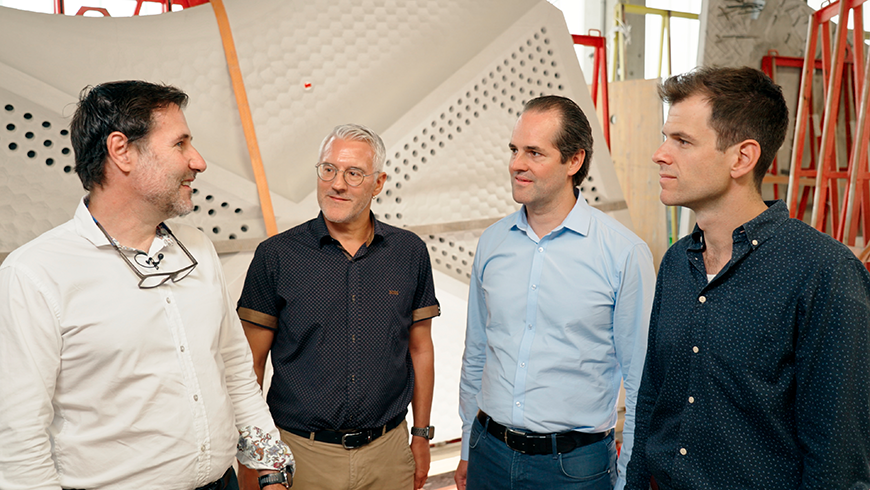

NEST, the research and innovation building of Empa and Eawag, aims to accelerate the innovation process in the construction industry. A key aspect of this is that players from different disciplines come together and develop new solutions for the construction sector. In this way, various industry partnerships have already emerged from different NEST projects over the past years. The most recent one: a strategic partnership between Stahlton Bauteile AG and zirkulit AG of Eberhard Unternehmungen. This was initiated by the joint work in the latest NEST unit STEP2, the construction of which will start shortly. "I am extremely pleased that with the STEP2 unit, together with our partner BASF, we can offer ideal conditions for the formation of such partnerships," says Enrico Marchesi, Innovation Manager at NEST and responsible for the project at Empa.

Paving the way to a sustainable future

The aim of the partnership is to turn the vision of a recyclable concrete house into reality. In the STEP2 unit, Stahlton Bauteile AG and zirkulit AG use the novel ribbed filigree slab to demonstrate what resource saving, innovative solutions they can create when they combine their expertise. The slab system was planned and developed by the architectural office ROK, the engineering office WaltGalmarini was responsible for the statics. The slab elements, produced using mineral and high-resolution 3D printing technology, are unique in Europe. Thanks to integrated acoustic modules equipped with Cavipor® absorber foam from STEP2 partner BASF, they absorb sound and thus ensure pleasant room acoustics. Thanks to the prestressing technology, the slab elements can be extremely slim. This saves around 40 to 50 percent of concrete compared to a conventional concrete flat ceiling with the same span width.

Nevertheless, where concrete cannot be dispensed with, the circular concrete zirkulit® is used. The two companies thus form the basis for circular buildings. Patrick Eberhard, member of the management board at Eberhard Unternehmungen, has been driving the development of circular building materials for years with his team around Reto Märki, managing director of zirkulit AG. He says: "We appreciate developments on real projects together with pragmatic partners. NEST offered us the ideal environment for this. This way, we get into concrete implementation together, which, also due to the consistent saving of primary resources, achieves the fastest and most sustainable progress." Samuel Suter, CTO at Stahlton Bauteile AG, adds: "We are already working on further projects to further optimize our circular components in terms of resource consumption and CO2 balance".

-

Share