Electromobility

Facts and figures on the life cycle of batteries

Electric cars are on the rise. On behalf of the Swiss Federal Office of Energy (SFOE), the research and consulting company INFRAS, together with researchers from Empa, has developed a basic report that identifies and answers relevant questions along the life cycle of traction batteries, from raw material extraction to their disposal.

Battery-powered vehicles are considered the key to decarbonizing transport. On behalf of the Swiss Federal Office of Energy (SFOE), INFRAS together with Empa has compiled the current state of knowledge around the topic of batteries for electric vehicles with a broad literature analysis. The resulting basic report is addressed to actors of the mobility industry, to the public administration as well as to media representatives.

The life cycle of a battery

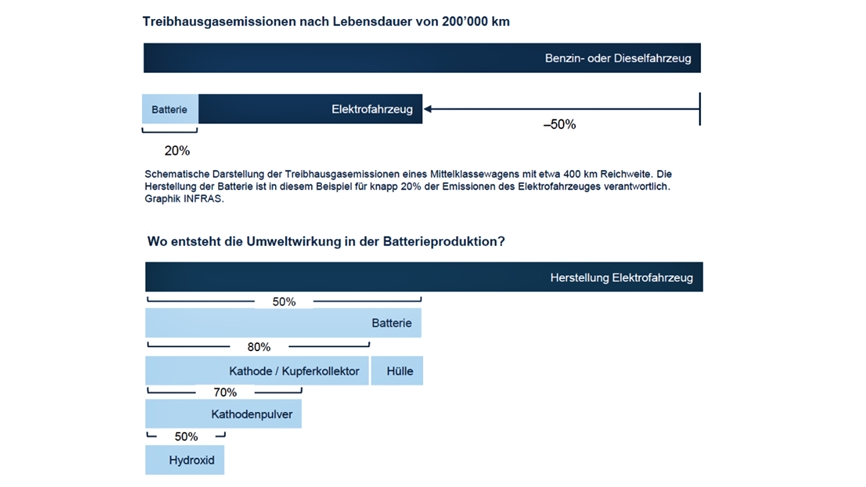

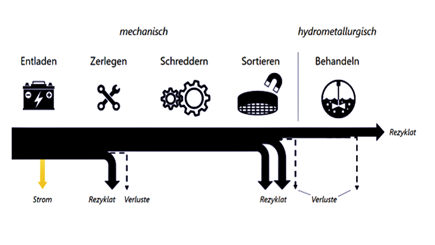

The basic report answers questions along the life cycle of a traction battery, from the extraction of raw materials and the production of battery cells to their use and end-of-life processes. The issues addressed include raw material availability, energy and material efficiency, environmental and social impacts, and safety. Empa researchers in the Technology and Society lab focused on the recycling of traction batteries.

Recycling of traction batteries

By recycling traction batteries, important raw materials such as lithium, cobalt, nickel and graphite can be recovered – after a possible secondary use. The recycling of these batteries is currently not yet profitable. However, recycling costs will decrease with increasing volumes as a result of economies of scale. At the same time, the development of novel recycling technologies will allow an increasing proportion of battery materials to be recovered in higher quality, thus increasing recycling revenues.

Roberto Bianchetti

Project leader, INFRAS

Dr. Patrick Wäger

Technology and Society, Empa

Phone +41 58 765 78 45

-

Share