Thin interlayers strengthen flexible composite materials

Cool satellites and flexible electronics

Ultra-light, super-flexible, highly insulating: An aluminum-coated polymer film is used to shield satellites from temperature extremes. Researchers at Empa have succeeded in making the material even more resistant by implementing an ultra-thin intermediate layer. The technology could in future also be used to improve flexible electronics and medical sensors.

The picture the pops up before our inner eye when we hear the word "satellite" is probably this: Two extended solar “wings” and a compact body wrapped in foil with a golden or silvery shimmer. Researchers at Empa's Mechanics of Materials and Nanostructures laboratory in Thun are now working to improve precisely this foil. As its widespread use indicates, the material is crucial for satellites and space probes. It is known as multilayer insulation or superinsulation and consists of several layers of a robust polymer coated with a thin layer of metal, usually aluminum. The coated film can also be encountered on Earth, for example in the form of survival blankets.

Aboard spacecraft, superinsulation protects the electronics from temperature fluctuations. "For satellites in low Earth orbit, the temperature difference between the sun-facing side and the side facing away is around 200 degrees. A similar temperature difference also occurs when a satellite flies into the Earth's shadow or out of the shadow back to the sunlit side of the planet – and this happens 16 times a day," says Empa researcher Barbara Putz. “Electronics work best at room temperature, though.” And since it is directly exposed to space conditions, the superinsulation itself must also be resistant to extreme conditions.

An extremely resistant polymer, polyimide, is most often used as the base for the thin-film structure. In addition to its temperature and vacuum resistance, this material is also characterized by the fact that the aluminum layer adheres to it particularly well. “The reason for this is an intermediate layer, just a few nanometers thin, that forms at the interface between the polymer and the aluminum during the coating process,” explains Putz. The researcher now wants to investigate this interface in more detail – and use the intermediate layer in a targeted way. It should not only enable better superinsulation for future satellites but also accelerate the development of flexible electronics back on Earth. She received an Ambizione Grant from the Swiss National Science Foundation (SNSF) for this research project.

Five nanometers make all the difference

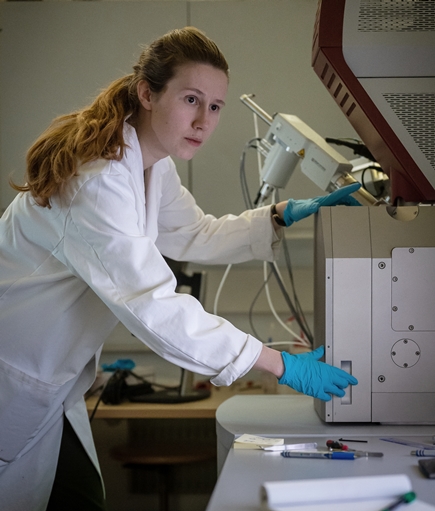

To better understand the intermediate layer and its effects on material properties, Putz and her doctoral student Johanna Byloff opted for a simple model system: a 50-micrometer-thick polyimide film coated with 150 nanometers of aluminum. Between the metal and the plastic, the researchers apply a coating of aluminum oxide measuring just five nanometers. Working with such a thin intermediate layer is challenging. To ensure clean processing, the researchers use a coating machine from the Empa spin-off Swiss Cluster AG, which was founded in 2020 by researchers from the Mechanics of Materials and Nanostructures laboratory. The device makes it possible to apply different coating processes to the same workpiece one after the other without removing it from the vacuum chamber.

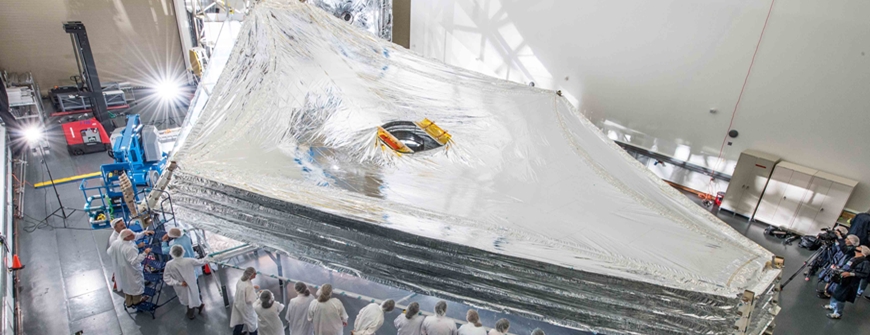

“We use the same combination of materials that is used for space applications, such as the European Mercury probe BepiColombo or the sunshield of NASA's James Webb Space Telescope,” says Byloff. “The difference is that the thin intermediate layer forms naturally in those applications, whereas we manufacture it specifically, which allows us to adjust its properties.” The space telescope's 21-by-14-meter sunshield also illustrates the demands placed on the composite material in space. In addition to the large temperature differences, the insulating layers are exposed to mechanical stress. “On the one hand, the sunshield was stowed away during transport of the telescope and had to unfold at its destination without the layers tearing or separating from each other,” explains Byloff. “On the other hand, particles and space debris can damage the film. It is important that the damage remains localized and does not spread as long cracks across the entire surface.”

From satellites to medical sensors

The researchers put their model film through its paces, subjecting it to tensile experiments and temperature shocks and characterizing it chemically and physically. The result: The new intermediate layer makes the material more elastic and significantly more resistant to cracks and flaking. Next, the researchers want to vary the thickness of the interlayer and apply it to other polymer substrates. “The natural interlayer can only form on a few polymers and only to a thickness of around five nanometers, which limits its usefulness,” says Barbara Putz. “We expect that our artificial interlayer will enable multilayer systems on other polymers that were previously out of the question due to poor coating adhesion.”

Satellite insulation is not the only area in which flexible multilayer systems are in demand. Putz and Byloff also see a major field of application for their research in flexible electronics, which are also based on metal-coated polymer substrates. Thin-film components for electronic devices usually have several layers made of different materials. But here, too, the mechanical properties could be improved through the targeted use of thin intermediate layers. This could advance the manufacturing of foldable or rollable devices, smart textiles, and flexible medical sensors, for example.

Dr. Barbara Putz

Empa, Mechanics of Materials and Nanostructures

Phone +41 58 765 62 54

Johanna Byloff

Empa, Mechanics of Materials and Nanostructures

Phone +41 58 765 63 12

J Byloff, COW Trost, V Devulapalli, S Altaf Husain, D Faurie, PO Renault, TEJ Edwards, MJ Cordill, D Casari, B Putz: Atomic Layer-Deposited Interlayers for Robust Metal–Polymer Interfaces; ACS Applied Materials & Interfaces (2025); doi: 10.1021/acsami.5c05156

Space technologies

Empa's research is conquering space. From components for space probes and imaging techniques for satellites to materials development on the International Space Station: Empa researchers are working on a wide range of materials and technologies for use at the “final frontier”. But no matter how high the research flies, it is still down-to-earth, as technologies for space have a variety of applications on Earth, whether for innovative electronics, medical devices, or monitoring environmental agreements.

Read the EmpaQuarterly online or download the PDF version.

-

Share