When damaged ropes change color

Hanging by a colored thread

High-performance fibres that have been exposed to high temperatures usually lose their mechanical properties undetected and, in the worst case, can tear precisely when lives depend on them. For example, safety ropes used by fire brigades or suspension ropes for heavy loads on construction sites. Empa researchers have now developed a coating that changes color when exposed to high temperatures through friction or fire.

The firefighter runs into the burning building and systematically searches room by room for people in need of rescue. Attached to him is a safety rope at the other end of which his colleagues are waiting outside in front of the building. In an emergency - should he lose consciousness for any reason - they can pull him out of the building or follow him into the building for rescue. However, if this rope has been exposed to excessive heat during previous operations, it may tear apart. This means danger to life! And up to now there has been no way of noticing this damage to the rope. A team of researchers from Empa and ETH Zurich has now developed a coating which changes color due to the physical reaction with heat, thus clearly indicating whether a rope will continue to provide the safety it promises in the future.

Researchers from ETH Zurich and Empa developed a coating system in 2018 as part of a Master's thesis, which the Empa team was now able to apply to fibers. "It was a process involving several steps," says Dirk Hegemann from Empa's Advances Fibers lab. The first coatings only worked on smooth surfaces, so the method first had to be adapted so that it would also work on curved surfaces. Empa has extensive know-how in the coating of fibers - Hegemann and his team have already developed electrically conductive fibers in the past (see links). The so-called sputtering process has now also been successfully applied to the latest coating.

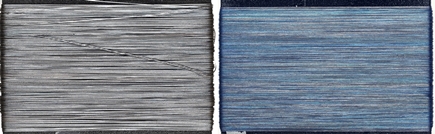

Wafer-thin layers with great effect

Three layers are required to ensure that the fiber actually changes color when heated. The researchers apply silver to the fibre itself, in this case PET (i.e. polyester) and VectranTM, a high-tech fibre. This serves as a reflector - in other words, as a metallic base layer. This is followed by an intermediate layer of titanium nitrogen oxide, which ensures that the silver remains stable. And only then follows the amorphous layer that causes the color change: Germanium-antimony tellurium (GST), which is just 20 nanometers thick. When this layer is exposed to elevated temperatures, it crystallizes, changing the color from blue to white. The colour change is based on a physical phenomenon known as interference. Two different waves (e.g. light) meet and amplify or weaken each other. Depending on the chemical composition of the temperature-sensitive layer, this color change can be adjusted to a temperature range between 100 and 400 degrees and thus adapted to the mechanical properties of the fiber type.

Tailor-made solutions

The possible areas of application for the colour-changing fibres are still open, and Hegemann is currently looking for possible project partners. In addition to safety equipment for firefighters or mountaineers, the fibres can also be used for load ropes in production facilities, on construction sites, etc. In any case, research on the subject is far from complete. At present, it is not yet possible to store the fibers for long periods of time without losing their functionality. "Unfortunately, the phase-change materials oxidize over the course of a few months," says Hegemann. This means that the corresponding phase change - crystallization - no longer takes place, even with heat, and the rope thus loses its "warning signal". In any case, it has been proven that the principle works, and durability is a topic for future research, says Hegemann. "As soon as the first partners from industry register their interest in our own products, the fibers can be further optimized according to their needs".

Empa assigns patent rights for textile fiber metallizing process to Swiss company, media release

Techtextil Innovation Award 2015: Chest strap heart rate monitor, media release

Noise reduction

A green earplug

Cars, trains, planes: For two thirds of the European population, traffic noise is part of everyday life. However, the right environment can have a major impact on this nuisance, as Empa researchers have found out. Green spaces in urban areas help to make road and railroad noise less of a nuisance. Only in the case of aircraft noise does this seem counterproductive: the greener the surroundings, the more disturbing the aircraft noise. More. (Image: Unsplash)

Sustainable fuels

Volatile stuff for heavy trucks

In future, commercial vehicles will not only have to emit less CO2 but also meet stricter exhaust emission limits. Many experts expect that this could herald the end for fossil diesel. One possible alternative is dimethyl ether: The highly volatile substance burns very cleanly and can be produced from renewable energy. Empa is investigating this new powertrain concept using a special test engine. More. (Image: istock)

Food technology

Drying fruit with ionic wind

If fruit or vegetables are dried with heat, nutrients can be destroyed and flavors can be reduced. This is why non-thermal drying of food – i.e. without heating – is preferred by the industry. Among other things, fans are used for this purpose. A new drying process developed at Empa using ionic wind promises to make the non-thermal drying of food much more energy-efficient, faster and even gentler. More.