New manufacturing process for electroactive polymers

Electrosprayed artificial muscles

Elastomers – also referred to as electroactive polymers (EAP) – transform electrical energy into mechanical energy and have a wide variety of applications, from powering windscreen wipers and generating sound to operating camera lenses. As an example of this, Optotune, a spin-off of ETH Zürich and Empa, have already launched infinitely focusable lenses of this type on the market. The principle is always the same: two electrodes are applied to the synthetic material, creating an electrical field. When voltage is applied, the material expands. When current no longer flows, the material contracts again. In a project entitled "SmartSphincter", part of the Swiss Nano-Tera research programme, researchers from the University of Basel and Empa have now developed artificial muscles for treating incontinence.

In order to operate effectively, micrometer-thick silicone layers need a voltage of several hundred volts, which is much too high for artificial muscles in the human body. Nanometer-thin layers, on the other hand, require only a few volts. Since the force exerted by these thin layers is very low, several thousand layers have to be put on top of each other in order to generate a sufficiently high force.

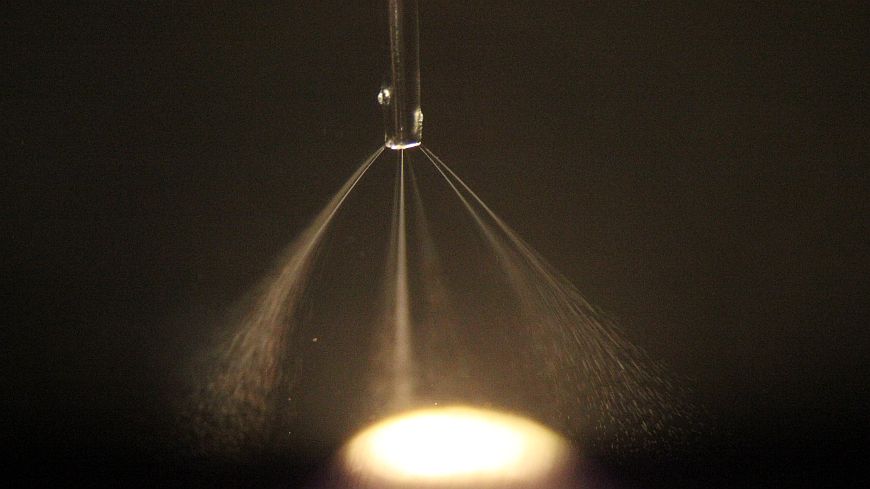

Coating using electrospray

However, the present manufacturing methods are not suited to the fabrication of such layered structures. Together with Florian Weiss and Gabor Kovacs from the Mechanical Systems Engineering department at Empa, the team headed by Bert Müller of the Biomaterials Science Center of the University of Basel developed a method of deposition which enables silicone layers to be fabricated that are much thinner than one micrometer. Furthermore, the layers are extremely flat: their surface roughness is less than one nanometer.

In the Empa lab, silicone molecules are vaporised with the aid of a high-voltage electrical current; this technique is known as electrospraying. Electrospraying is normally carried out using direct current. For the development of artificial muscles, however, the Empa scientists are experimenting with alternating current. Several thousands of layers created in this way can be built up to create artificial muscles which require an operating voltage of only 40 volts. This corresponds roughly to the voltage of a button cell. The researchers hope that this technology can soon be used to produce an implant for treating incontinence.

This comparatively simple manufacturing process is highly suitable for industrial production and offers tremendous potential for the fabrication of artificial muscles which could be used, for example, to power windscreen wipers. In another Empa spin-off entitled Compliant Transducer Systems, Gabor Kovacs is also working on artificial muscles which can be manufactured in large quantities. Kovacs' goal is to produce low-cost polymer actuators which can be manufactured by the millions to be used, for example, in motor vehicles, where they could operate a range of flaps, mirrors and lamps, or in industrial automation to drive grippers, switches and valves.

Information

Dr. Gabor Kovacs

Empa, Mechanical Systems Engineering

Phone +41 58 765 40 63

Prof. Dr. Bert Müller

Universität Basel, Biomaterials Science Center

Phone +41 61 207 54 31

Editor / Media contact

Martina Peter

Empa, Communication

Phone +41 58 765 49 97

Electrospraying Nanometer-Thin Elastomer Films for Low-Voltage Dielectric Actuators, FM Weiss, T Töpper, B Osmani, S Peters, G Kovacs, B Müller, Adv Electr Mat (2016), doi: 10.1002/aelm.201500476

Thin Film Formation and Morphology of Electro-sprayed Polydimethylsiloxane, FM Weiss, T Töpper, B Osmani, H Deyhle, G Kovacs, B Müller, Langmuir (2016), doi: 10.1021/acs.langmuir.6b00476

Artificial Muscle Devices: Innovations and Prospects for Fecal Incontinence Treatment, E Fattorini, T Brusa, C Gingert, SE Hieber, V Leung, B Osmani, MD Dominietto, P Büchler, F Hetzer, B Müller, Annals Biomed Engin (2016), doi: 10.1007/s10439-016-1572-z

-

Share