|

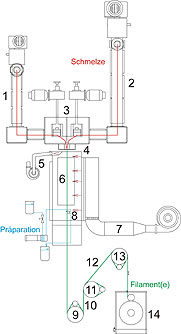

However, less common thermoplastic base materials (for example

bioengineered plastics or “bioplastics”) can also be

used. There are a host of potential combinations that have yet to

be explored. With Spider fibres can not only be produced on a

laboratory scale, their composition and formulation can be

constantly varied with relatively little time and effort, something

which cannot be cost-effectively achieved in industrial plants. The

numerous characterization options open to Empa mean that the

properties of these new fibre types can be scientifically

predicted.

Special techniques such as plasma coating make it possible to

construct complex fibre structures and to undertake selective

chemical modifications on the fibre surface. In this way the

chemical and physical properties of the fibres can be influenced as

required, for instance their hydrophilic properties, strength,

shrinkage characteristics and elasticity. It is also possible to

incorporate nanoparticles in the cladding region to achieve a

desired functionality.

New prospects for bi-component fibres

The object of this research is to identify fibres with specific

properties for use in functional or “intelligent” textile

materials for clothing, technical and medical textiles or fibre

composites. Possible functions of these innovative textiles include

the controlled release of drugs in medical plasters, shock

absorbers in protective clothing, temperature control in

firemen’s suits or sportswear and applications in sensor

technology (for instance changing colour to indicate environmental

changes). Materials can thus be tailored to make them

biocompatible, biologically degradable, moisture-repellent or extra

absorbent, flame-retardant or odour-reducing as needs demand.

One particularly promising avenue is the application of

high-grade polymers in the form of a coating on a core made of

standard polymer with resultant savings in raw materials and

costs.

Another idea with great potential is to manufacture fibres with

photovoltaic properties. These could convert the energy of light

into electric current, turning a suit into a power plant as it

were. It’s good to know that Empa’s new spinning machine

for bi-component fibres is playing a part in this.

|