Build digitally

"co-operate" times two

Digital construction using Building Information Modeling – BIM for short – is a trend for the future: more efficient, less expensive and more transparent, from design to operation of the building. The new Empa and Eawag research campus is now being built with the help of a digital twin, which will also simplify facility management of the new buildings.

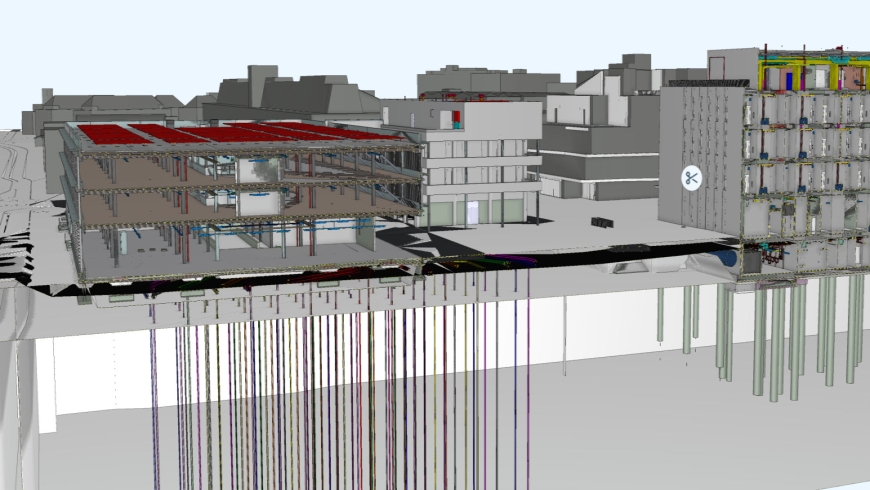

Around 3,800 cubic meters of concrete for foundations and floor slabs under the building, more than 2,450 square meters of windows and almost 13,000 meters of electrical cables: information about the current planning status of the future Empa research campus, delivered with just a few mouse clicks – with the help of a digital model. This is the nucleus for a completely virtual twin that makes detailed planning, execution and operation more efficient.

This way of working is based on the BIM method, which has become increasingly important in recent years (see info box). Technical regulations such as Code of Practice 2051 of the Swiss Society of Engineers and Architects (sia) now describe exactly how to proceed – for instance, when planners and companies work with which data, and how. After all, the task is complex: The digital building "grows" – just like its role model in the real world – thanks to a wide range of information on the building materials, lines and built-in parts, which in turn are linked to dozens of "attributes": from data on prices and delivery dates to instructions for subsequent operation.

New process, new insights

The advantages of the process: The digital twin makes the project more transparent for everyone involved – for example, in terms of construction progress and running costs. Or even in the case of changes, which are almost unavoidable in larger projects: Using the model, contradictions or discrepancies can be spotted quickly. Granted, the effort is initially higher than with conventional projects, says Stephan Mülhaupt from Empa's Real Estate Management team, but as the project progresses the new method pays off.

It's an exciting experience that has its pitfalls. "If, say, building components are recorded in too much detail, there is a risk at some point that data volumes will become too large," says Mülhaupt, "This is also a learning process for us." The Empa experts are supported by specialists from Cadmec AG, who have experiences from numerous previous projects.

What is special about the co-operate campus project? "There really is an extraordinary amount of information flowing from the digital models of the planners into the overall model," says André Wegener, who is responsible for the project. "The planners feel that they can pick up and involve the building owners much better with digital communication tools based on the model. This leads to faster and more transparent decisions."

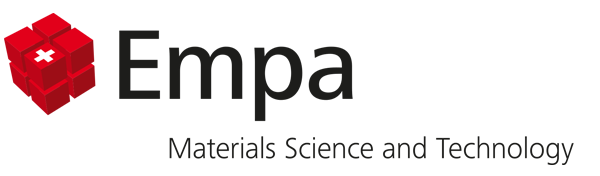

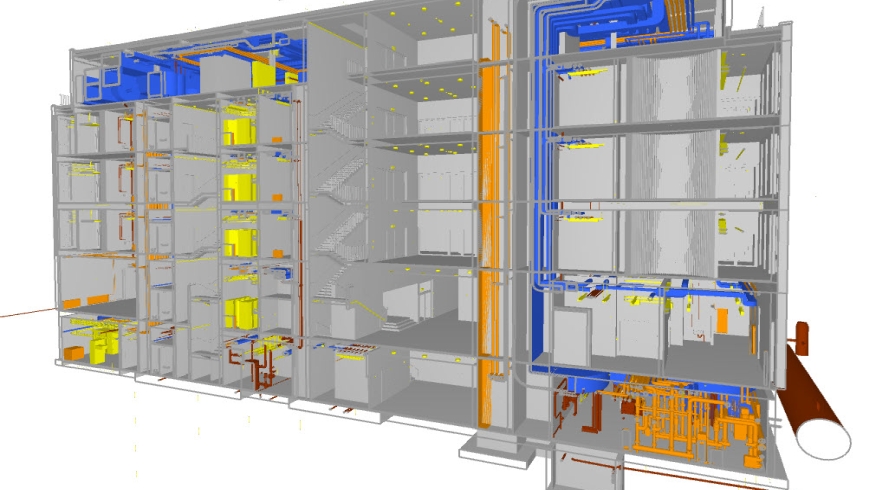

Currently, the images of the laboratory building and the multifunctional building with the garage already contain data for electrical engineering, ventilation systems, heating technology and other systems, as well as the model for the geothermal probes. As ICT coordinator, Wegener makes sure the complex data transfer runs smoothly between the numerous participants – one of the new job roles that have emerged because of digitized construction.

The project will end with the fusion of the data into an "As Built Model": an exact digital representation of the entire real-world co-operate infrastructure – from the foundation concrete with its reinforcement to the ceiling lights including electrical wiring. It is intended not only as a source of information, but also for facility management. A simple example: Window and floor areas of the buildings can be generated from the model with just a few mouse clicks in order to efficiently plan cleaning cycles.

Data as a beacon of hope

In the future, of course, digitization could offer many more opportunities, for example for sustainable construction. BIM data could be used to optimally position buildings for sunlight or ventilation and thus save energy. Or to optimize material cycles for water and energy during operation. And even after the end of a building's service life, the exact knowledge of materials and components would be useful in order to feed them back into the material cycle after demolition.

Such perspectives convince experts like Stephan Mülhaupt that the effort of digitization is worthwhile. "Nowadays, it's mainly highly complex construction projects that are realized with the help of digital twins," he says, "but the more experience industry gains, the faster this way of working will become established." And at some point, he hopes, the benefits will then trickle down to smaller projects like residential buildings.

Pioneering BIM projects

The BIM method has so far been used primarily for complex construction projects. In Germany, the new building of the Frankfurt Höchst Clinic was designed digitally in order to be able to optimize the complex routes of people and transport in this large-scale structure. In addition, BIM was to help meet the passive house standard. Deutsche Bahn also plans to make extensive use of the process in the future and tested it in the planning of the Rastatt tunnel. In Switzerland, the Felix Platter Hospital in Basel was built in this way: Architects and specialist planners, for example for building or medical technology, as well as the developer cooperated with digital models. The resulting data was finally merged into a model to be used for facility management. The innovative project was honored with the buildingSMART International Award 2016.