Bâtiment respectueux du climat

Isolation à partir de bouteilles vides

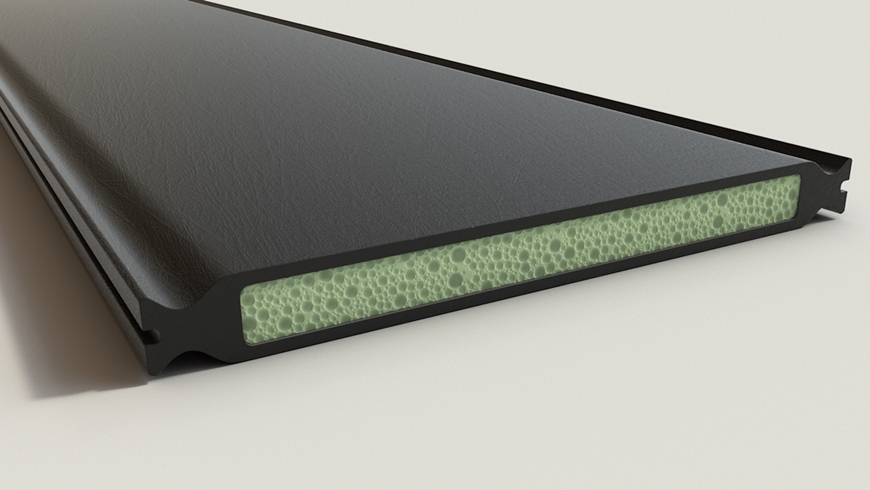

Les bandes isolantes sont essentielles pour une bonne isolation thermique des profilés de fenêtres et des façades en aluminium. Les chercheurs de l'Empa et leurs partenaires travaillent depuis un certain temps sur un nouveau type de produit "sandwich" dont le remplissage est écologique : du matériau recyclé provenant de bouteilles en PET. La mise sur le marché est maintenant imminente - avec de bonnes perspectives de succès.

Elles sont encore mieux cachées que les vis, dont on peut au moins encore voir les têtes, mais elles sont tout aussi omniprésentes : des bandes isolantes sont collées à l'intérieur des profilés en aluminium et en métal pour les fenêtres et les vitrages de façade - comme isolateurs thermiques entre l'extérieur et l'intérieur, car sinon le froid ou la chaleur circuleraient sans contrôle à travers le métal. Un composant discret, en d'autres termes, qui devient encore plus important avec le réchauffement climatique et la nécessité de réduire les émissions de CO2.

Mais bien qu'elle soit établie depuis plus de quatre décennies, la bande isolante a un potentiel d'amélioration. Une équipe de l'Empa dirigée par Michel Barbezat et Giovanni Terrasi du département Génie des systèmes mécaniques travaille sur un nouveau type de produit - avec des experts de l'entreprise de construction métallique Hochuli à Wigoltingen, qui a fondé à cet effet sa propre société sœur "hochuli advanced".

Le point fort de la bande isolante "Alpet" : à l'intérieur du plastique renforcé de fibres de verre se trouve une bande de mousse en polyéthylène téréphtalate - PET, autrement dit, provenant de bouteilles en PET recyclées.

Les nombreux pores d'air de cette couche isolent efficacement : la conductivité thermique des prototypes est en moyenne, en fonction de la largeur de la bande, d'environ 0,1 W/mK - bien moins qu'une bande isolante standard en polyamide (environ 0,25 W/mK) et aussi nettement moins que les produits haut de gamme disponibles aujourd'hui.

Régler de nombreux détails

Une approche simple, comme cela semble être le cas à première vue - mais pour transformer l'idée en produit, un travail conceptuel important a été nécessaire dans le cadre d'un projet Innosuisse. Prenons par exemple la méthode de production : après avoir testé différents procédés, les experts ont opté pour ce que l'on appelle l'extrusion, dans laquelle le plastique fondu et chauffé est pressé à travers une fente sous forme de pâte molle et façonné de cette manière - autour de la bande de PET. Mais cela soulève à son tour des questions, par exemple sur la proportion de vides d'air dans ce "remplissage".

"Autant que possible" est la réponse, afin d'obtenir un effet isolant important. Seulement : "Trop" mettrait en danger la stabilité du brin de PET préparé, car son encastrement dans le plastique noir se fait à des températures allant jusqu'à 300 degrés et sous haute pression.

Les chercheurs ont également adapté l'épaisseur de cette "coque" aux nécessités : aussi étroite que possible pour un bon effet isolant - mais suffisamment épaisse pour que la bande puisse ensuite bien résister aux contraintes mécaniques ; y compris le post-traitement du profilé global fini, comme le revêtement en poudre ou l'anodisation.

À partir de nombreux échantillons, les développeurs ont distillé sept variantes pour les tester - soit un total d'environ 1 000 mètres de bande isolante - et les ont finalement utilisées pour créer le prototype final qui servira de base aux produits finis.

Une étape importante du processus de production a également été réalisée de cette manière : La bande se soude pratiquement d'elle-même grâce à la chaleur - sans qu'il soit nécessaire de coller un autre "joint".

"C'est déjà un gros avantage", déclare Frank Hochuli, ingénieur en construction métallique, du partenaire industriel. "Il n'y a pas de points faibles locaux où le matériau pourrait se détacher. Et moins il y a d'étapes, plus le produit est bon marché."

Un long processus qui a fini par porter ses fruits, comme le constate également Michel Barbezat, chercheur à l'Empa. "Techniquement, nous avons certainement de très bonnes chances", dit-il. Les valeurs mesurées et le produit, qui peut être facilement recyclé malgré l'utilisation de deux matériaux, sont déjà convaincants. Et les experts sont également confiants quant à la stabilité à long terme nécessaire sur de nombreuses années, que son équipe a tenté d'estimer à l'aide d'expériences et de la méthode innovante des " Stepped Isostress" (voir encadré).

Tests indépendants en Allemagne

Michel Barbezat reconnaît qu'il n'est pas facile de convaincre une grande entreprise de systèmes qui fabrique et vend des profilés pour les fabricants de fenêtres de coopérer. "Après tout, par rapport aux grandes entreprises, nous ne sommes rien", dit-il. C'est pourquoi les partenaires ont envoyé leur bande isolante "Alpet" à l'institut de contrôle ift de Rosenheim, en Bavière, qui est une référence dans le secteur depuis des décennies.

Les experts n'ont pas seulement répété les tests suisses, mais ont également soumis les prototypes à des essais au feu, à des essais de rupture et à d'autres contraintes - par exemple, à des microfissures invisibles après 1000 heures de stockage dans l'huile ou l'acide léger, ou à une forte tension dans le sens transversal. Selon Frank Hochuli, les certifications officielles pour le comportement au feu, la capacité de charge statique et pour l'isolation thermique ont maintenant été délivrées.

Plus respectueux de l'environnement avec peu d'efforts

Quel effet la nouvelle bande isolante aurait-elle sur l'ensemble du système "fenêtre", y compris les vitres, les profilés en aluminium, les joints et tous les autres détails ? Par rapport aux conceptions haut de gamme actuelles, Frank Hochuli estime que l'isolation thermique d'un nouvel immeuble de bureaux, par exemple, pourrait être améliorée de près d'un cinquième. Et comme la bande isolante, avec sa "queue d'aronde" comme raccord de montage, est compatible avec tous les systèmes courants, les solutions existantes peuvent être mises à niveau relativement facilement - par exemple, pour répondre aux exigences élevées des normes relatives aux maisons passives. "Avec les profilés en aluminium, on ne peut le faire que très difficilement de nos jours, dit-il, notre système faciliterait certainement les choses."

Des tests détaillés sont ensuite effectués par les fabricants eux-mêmes, dans leurs propres laboratoires, avec leurs propres systèmes de profilés. Des discussions ont eu lieu à ce sujet ; les premiers clients commencent déjà à faire des essais. "Je suis résolument optimiste", déclare M. Hochuli. "Sinon, je n'aurais pas fondé une entreprise pour mettre notre idée sur le marché". Mais le projet ne fera pas cavalier seul : les experts de l'Empa continueront à soutenir la bande isolante avec leur savoir-faire après de nombreuses années d'accompagnement.

La méthode "Stepped Isostress"

Comment un composant en plastique se déforme-t-il sur une période de 30 ans ou plus - sous une charge continue et de grandes différences de température ? Les "essais de fluage" courants effectués en laboratoire pendant plus de 1000 heures sous des charges thermomécaniques combinées ne permettent pas de faire des déclarations sérieuses.

Cependant, pour pouvoir faire des prévisions à long terme, de nouvelles méthodes ont été développées et affinées ces dernières années, dont la "Stepped Isostress Method" (SSM) que les experts de l'Empa ont appliquée à la nouvelle bande isolante.

En termes simples, les déformations de nombreux essais individuels avec des charges croissantes sont additionnées pour former une "courbe maîtresse", qui fournit des informations sur de plus grandes périodes de temps.

Cette procédure peut également être réalisée en une seule fois, avec des charges augmentant progressivement, et facilite l'étude simultanée de plages de températures critiques.

Dr. Michel Barbezat

Laboratory for Mechanical Systems Engineering

Tél. +41 58 765 44 98

michel.barbezat@empa.ch

Frank Hochuli

Directeur général Hochuli advanced

Tél. +41 52 762 04 02

frank.hochuli@hochuli-advanced.ch

Norbert Raabe

Communication

Tél. +41 58 765 44 54

redaktion@empa.ch

Page d'accueil de l'entreprise Hochuli advanced à Wigoltingen