Integrity of Mechanical Components

Our research integrates materials science and mechanical engineering to ensure the reliability of mechanical components operating under challenging conditions—such as high temperature and/or hydrogen exposure.

We employ analytical and experimental methods to investigate the mechanical behaviour and degradation mechanisms of materials. Building on these insights, we develop physics-based predictive models and apply advanced computational techniques—including tools from scientific machine learning—to support the assessment of real-world components, thereby bridging fundamental science and engineering practice.

Mechanical Integrity at Ambient and Elevated Temperatures

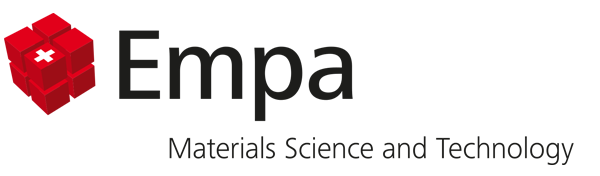

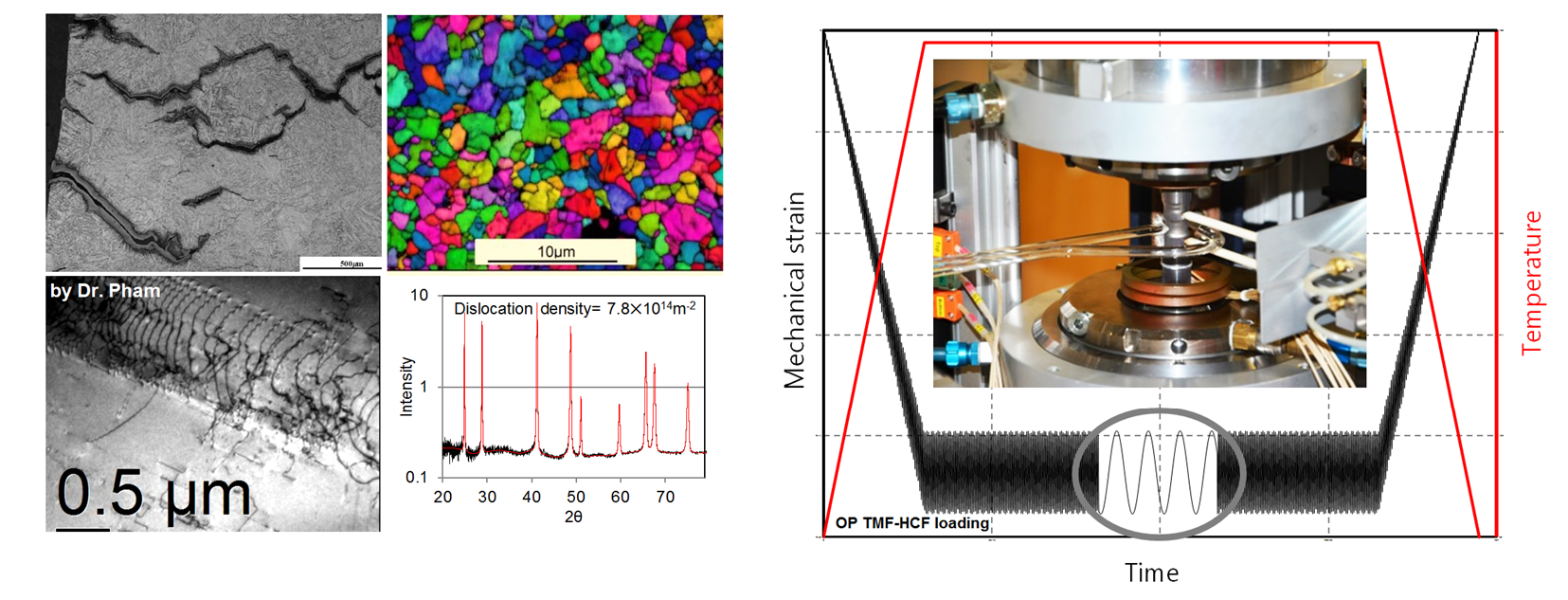

- Characterisation of the mechanical response of materials (deformation and damage behaviour, creep/fatigue/thermomechanical fatigue) over a wide range of temperatures for conventional and additively manufactured materials

- Material microstructure characterisation (pre- and post-test inspection)

- Understanding the correlation between material’s microstructure and its mechanical response

- Development of material constitutive models for deformation/damage and implementation into FEA

- Integrating scientific machine learning and stochastic modelling for computationally efficient probabilistic mechanical integrity assessment

Mechanical Integrity in Hydrogen Environment

- Microscopy-based inspection of hydrogen damage mechanisms in materials (embrittlement, high-temperature hydrogen attack, blistering, and rapid gas-decompression damage)

- Physics-based modelling of hydrogen-assisted degradation and fracture (coupled stress–chemical potential frameworks)

- Mechanical testing of materials under hydrogen exposure at ambient and elevated temperatures across a wide range of gas pressures

- Mechanical integrity assessment of hydrogen-critical components, such as high-pressure pipelines, following established codes and guidelines (ASME B31.12, DVGW G 464)