|

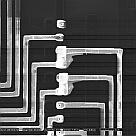

These secondary electrons, as they are called, give information

about the topography and material characteristics at the point

where the (primary) electron beam strikes the sample surface. The

primary electron beam is scanned point by point and line by line

over the sample, as in a television picture, giving a detailed and

greatly magnified image.

The advantage of the FIB over the SEM lies in the fact it uses a

gallium ion beam, and gallium ions are orders of magnitude heavier

than electrons, so that the interaction of the ion beam with the

sample is much more pronounced. If the electron beam were likened

to the beam of a torch, then the ion beam would be comparable to a

very powerful but finely controllable laser beam. The laser beam,

to continue the analogy, causes material from very precisely

targeted points on the surface of the sample to be knocked out, a

process called sputtering. This is exactly what happens in the FIB,

on an incredibly small scale. A by-product of the bombardment with

gallium ions is, of course, secondary electrons which are also

ejected. These allow an image of the sample to be generated (in

addition to the other FIB operations on the sample) which is of

similar quality to that produced by a good SEM.

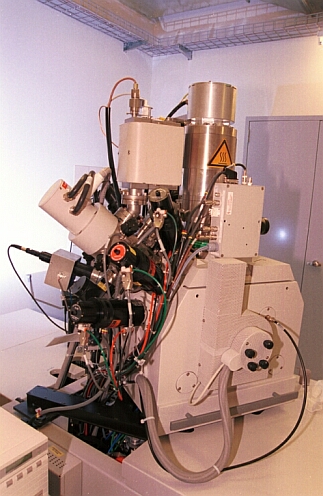

The «dernier cri» of FIB technology is the

combination of FIB, gas chemistry and classical SEM in one machine.

This set-up is known as Dual-Beam FIB, and multiplies the

advantages of the FIB with those of classical scanning electron

microscopy. The Dual-Beam FIB technique has advantages in certain

applications, such as the rapid and precise preparation of samples

for transmission electron microscopy (TEM). While TEM is capable of

even greater magnification than SEM, sample preparation was

traditionally a specialization mastered by very few experts in the

field. One of the two systems at Empa is a Dual-Beam FIB.

|