Never miss an issue

Subscribe to our magazine

Insights

Curry powder? No, titanium!

The fine powder in this container may seem tempting to friends of healthy spices – but it is definitely inedible: a titanium alloy made of fine grains averaging 35 micrometers in diameter.

Nevertheless, the powder is in the service of human health. The fine-rough structures an expert is gently wiping free by hand are the tops of medical implants: hip sockets for people who need a joint replacement. They were created with the help of laser beams that burned them out of the powder layer by layer – so the photo depicts the final stage of production in a 3D printer.

You can read more about this innovative medical technology and its opportunities and pitfalls in our photo feature story which you can find here.

>>>>

In brief

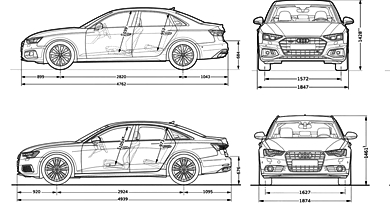

Automobile society of classes

In order to correctly separate vehicles into classes, for example for mobility pricing, one must be able to clearly distinguish mid-sized cars from upper class cars and small cars from compact cars. But this is becoming increasingly difficult: in photos, an Audi A4 looks almost the same as an Audi A6, a Mini One looks similar to a Mini Countryman. To date, there is no independent procedure for this. Until now, the classes in each country have been divided by experts – to a large extend at their own discretion. Empa researcher Naghmeh Niroomand has now developed a system that can classify cars worldwide based on their dimensions. Purely mathematical and fair. Thanks to it, the current classification by experts could soon be a thing of the past. At the same time, car classes would be easier and more objectively comparable worldwide. After all, a "mid-size car" is something different in Italy than it is in the USA.

>>>>

Mask check via App

Until now, only the mask itself knew whether the Corona mask on one's face provided sufficient protection in a given situation. Empa researcher Flora Bahrami has now developed an App that can predict the maximum duration of protection in the presence of people who are infected. Depending on the type of mask type, location and activity level, the App calculates how long the situation will be safe. This results in different times for a workout with coughing athletes in the gym or taking a bus along with silent passengers. Also visible: how many viruses one has potentially inhaled, depending on the type of mask and length of stay. "Mask manufacturers can also use the App to optimize product development," says Bahrami.

>>>>

Extended protection against germs

Extended protection against germs

A team from Empa and the medtech company Lumendo (VD) is currently developing a hand disinfectant that provides protection that will last several hours. The long-term effect of Disigel is based on a gel that is gentle on the skin but kills germs. The gel is intended to protect against antibiotic-resistant bacteria and pandemic viruses. The project is supported by Innosuisse, the Swiss Innovation Agency. The effect of Disigel is currently being tested in the lab.

>>>>

From dismantling to re-use

Another construction site at NEST: With the new Sprint unit, NEST gets an office unit built largely from recycled materials. Sprint aims to set new standards for circular construction. However, the office unit is also a reaction to the current COVID-19 situation, which made it clear that we need to adapt our buildings more flexibly and quickly to changing needs.

>>>>

Editorial

3D printing for professionals

3D printing is now "mainstream"; the Internet is abuzz with more or less useful templates for 3D printers, which are now available on almost all eCommerce platforms. So far, so boring.

But manufacturing a medical implant to replace a defective hip joint, for example, is probably something that very few hobby 3D printers would dare to do. And quite rightly so, as our photo report from the "Swiss m4m Center" in Bettlach, Solothurn, shows (starting on p. 20). There, patient-specific implants will be created layer by layer from a bed of metal powder. This is a multi-stage, extremely complex process that requires an enormous amount of materials and process engineering expertise.

The "Swiss m4m Center" is the first "Advanced Manufacturing Technology Transfer Center", a Swiss-wide network that is intended to give local industry a technological edge over international competition in the field of advanced manufacturing technologies.

Incidentally, this idea originated at Empa as a kind of extension of our "Coating Competence Center". It's good to see that this is now bearing fruit: The m4m network now counts almost 50 partner institutions.

Michael Hagmann, Head of Communication

Concrete

Prestressed plasters for old buildings

The technology of stabilizing concrete structures with carbon fiber-reinforced polymers, thus helping them to last longer, was developed decades ago; among others at Empa. Today, researchers in Dübendorf are working on a new variant with prestressed lamellas – with good prospects for practical application.

>>>>

Flame retardant textiles

Fireproof and comfortable

A new chemical process developed by Empa turns cotton into a fire-resistant fabric, that nevertheless retains the skin-friendly properties of cotton.

>>>>

Interview

"Recycling is not always sustainable"

>>>>

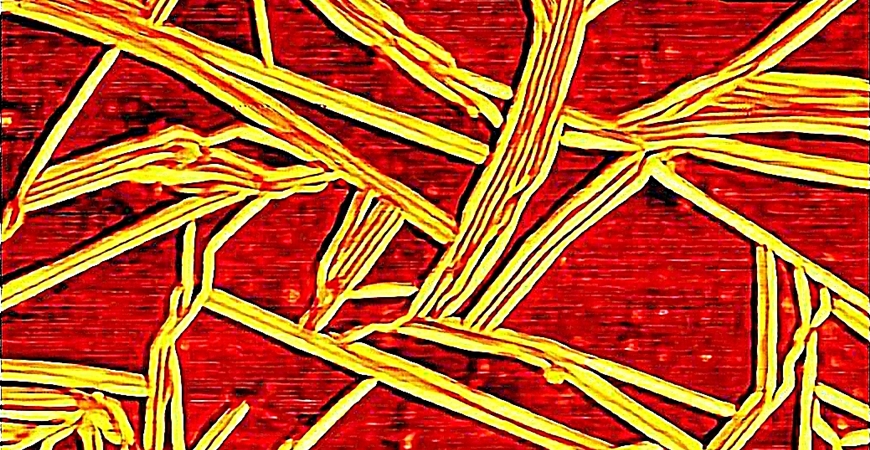

Solid state physics

Filigree chemistry for mega crystals

An international team led by Empa and ETH Zurich researchers is playing with shape-engineered nanoscale building blocks that are up to 100-times larger than atoms and ions. And although these nano "Lego bricks" interact with each other with forces vastly different and much weaker than those holding atoms and ions together, they form crystals all by themselves, the structures of which resemble the ones of natural minerals. These new mega-crystals or superlattices that are depicted on the cover of the latest issue of "Nature" exhibit unique properties such as superfluorescence – and may well usher in a new era in materials science.

>>>>

Foto story

From titanium powder to a hip socket

Additive Manufacturing, AM in brief, is fascinating: As if by magic, complex workpieces grow in 3D printers: layer by layer by layer ... – without human intervention, as it may seem at first glance. But the technology is demanding and requires a lot of manual work with a sure touch, as a visit to the expert team at the Swiss m4m Center in Bettlach shows.

>>>>

Better fibers

A jacket from a jacket from a jacket ...

Manufacture, wear, wash, incinerate: This typical life cycle of garments, which pollutes the environment, is to be changed in the future – towards principles of circular economy with recycling at its core. Using an outdoor jacket made from PET bottles and recycled materials, Empa researchers have investigated whether the product actually delivers what the idea promises.

>>>>

Gloss

RIP, Hypatia …

Hypatia, the joint cluster computer of Empa and Eawag, is no more. On 10 March, the well-behaved and fast helper for scientific simulations was dismantled in Empa's basement and loaded onto the trucks of a waste disposal company. Many components of the mainframe will now begin a new life elsewhere. Hypatia was named after one of the few female scientists of antiquity who lived in Egypt in the 4th century.

>>>>

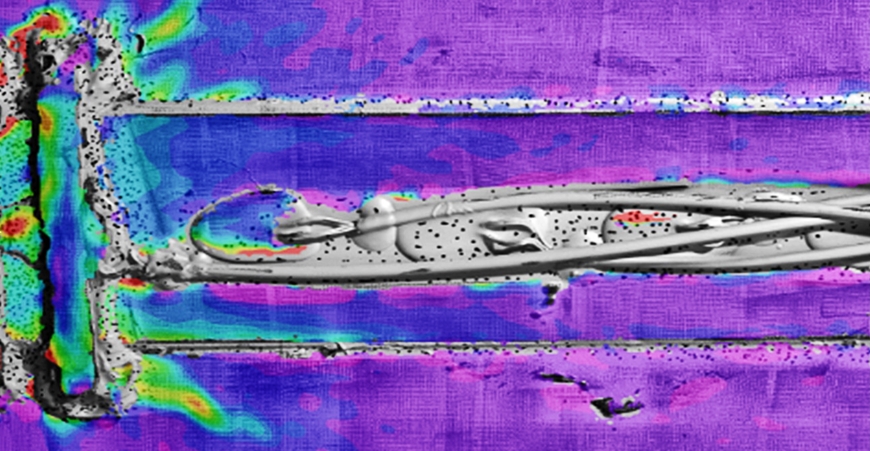

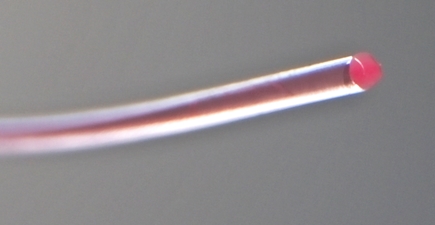

Fibers

A data river runs through it

Data and signals can be transmitted quickly and reliably with glass fibers – as long as the fiber does not break. Strong bending or tensile stress can quickly destroy it. An Empa team has now developed a fiber with a liquid glycerol core that is much more robust and can transmit data just as reliably. And such fibers can even be used to build microhydraulic components and light sensors.

>>>>

Rising energy demand for cooling

Some like it cool

Climate-related temperature rises will further increase the cooling demand of buildings. A projection by Empa researchers based on data from the NEST building and future climate scenarios for Switzerland shows that this increase in energy demand for cooling is likely to be substantial and could have a strong impact on our future – electrified – energy system.

>>>>

On the road

Nest opens its virtual doors

Nest opens its virtual doors

Until now, tours of NEST have only taken place live and on site. Since June 2021, the entire building can also be visited online and spontaneously. Guests on the virtual NEST tour can visit the individual building modules – known as units – as well as the Energy Hub (ehub) and Water Hub research platforms and move freely through the building. The tour takes them to experts who share their know-how directly with the guests. What's more, there are countless innovative materials, technologies and processes to discover. The virtual tour runs on PC and Mac, smartphones and tablets.

>>>>

Empa at the Institute of Bioinformatics

In January 2021, Empa joined the Swiss Institute of Bioinformatics (SIB) as a new member institution. The SIB is an academic non-profit organization whose vision is to promote excellence in data science for progress in biological research and health. Members include research groups from the most important Swiss universities and research institutes. Empa is represented by the group "Multi-omics for healthcare materials" led by Marija Buljan. The group is part of Peter Wick's "Particles-Biology Interactions" lab and focuses on the unfolding of disease-associated cellular signaling networks to find precise solutions for immunoengineering. The group's activities focus on the generation and analysis of biomedical multi-omics datasets that can support the development of new materials for personalized health applications.

>>>>

Strategist for energy storage

The umbrella organization of the renewable energy and energy efficiency industry (AEE Suisse) has launched a new working group "Electrical Energy Storage" in May 2021. The group consists of renowned battery specialists, such as Andrea Vezzini, head of the Energy Storage Research Center at the Bern University of Applied Sciences and Arts, and Jonas Mühlentaler from the Institute of Electrical Engineering at the Lucerne University of Applied Sciences and Arts. Empa is represented by Marcel Gauch, an expert in electromobility and also Empa's sustainability delegate. Another Empa-trained expert on the working group is Olivier Groux, project manager for development at Kyburz AG.

Batteries

Electrical supply without worries

The number of data-transmitting microdevices, for instance in packaging and transport logistics, will increase sharply in the coming years. All these devices need energy, but the amount of batteries would have a major impact on the environment. Empa researchers have developed a biodegradable mini-capacitor that can solve the problem. It consists of carbon, cellulose, glycerin and table salt. And it works reliably.

>>>>

Diagnostics

Early detection of dementia

Alzheimer's and other dementias are among the most widespread diseases today. Diagnosis is complex and can often only be established with certainty late in the course of the disease. A team of Empa researchers, together with clinical partners, is now developing a new diagnostic tool that can detect the first signs of neurodegenerative changes using a sensor belt.

>>>>

Molecular diagnosis

Detecting Alzheimer's in blood

Empa researcher Peter Nirmalraj wants to capture images of Alzheimer's peptides with unprecedented precision. This could allow new insights into the molecular pathogenesis of the neurodegenerative disease – and perhaps open the way to new therapies.

>>>>