Flexo Printing

Flexo printing is a widely-used printing technique in the packaging industry. It utilizes relief elements on a flexible printing plate or cylinder to transfer the ink to the substrate. It is essentially a modern letterpress.

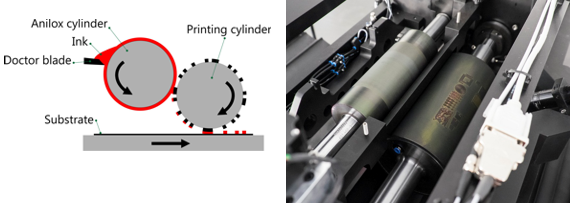

Schematic of the Flexo printing process and printing unit of the C600

Key features

- Relief elements on a flexible printing plate can print on nearly any type of substrate

- High variety of low viscosity inks can be used (UV, solvent, waterbased etc.)

- Anilox roller made of chrome/ceramic

- Web speed ≤ 80 m/min

- Mass-printing technique

- Resolution ≥ 150 dpi, ≤ 20μm

- Film thickness 0.1 – 3 μm

Flexographic printed silver electrodes and test structures. 3-D image to determine layer-thickness (~100 nm for the printed Ag structures)